Abstract

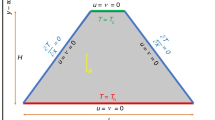

Using finite element method (FEM), the complex flow fields of quenching medium in a quenching tank are calculated for the cases with and without a workpiece in it. The influence of the flow homogenization device on the flow fields is studied. The computer simulation results are in consistency with the actual measurement results. According to the simulated results, the structure of the quenching tank and the flow homogenization device are optimized and more uniform flow fields are obtained.

Similar content being viewed by others

References

Yuan Wenqing, Chen Xiao, Hu Mingjuan et al., Computer simulation of three-dimensional temperature fields in a heating workpiece, Journal of Heat Treatment of Metal, 1991(12): 35–41.

Hu Mingjuan, Pan Jiangsheng, Li Bing et al., Computer simulation of three-dimensional temperature fields in an interface condition severely changed quenching process, Journal of Heat Treatment of Metal, 1996, 17: 90–97.

Dowling, W., Pattok, T., Ferguson, B. L., Development of a carburising and quenching simulation tools and program overview, Heat treatment of Metals, 1997(1): 1–6.

Gergelly, M., Somogyi, S. Z., Computerized property prediction and process planning in heat treatment of steel, Material Science Forum, 1994(163–165): 657–666.

Quan Yutai, Computer simulation of temperature fields, stress fields and structure transformation during heat-treatment process, Journal of Yu Zhou University (in Chinese), 1999, 16(2): 51–54.

Inoue, T., Arimoto, K., Implementation of program for simulating heat treatment processes and some results, Industrial Heating, 1995(4): 41–45.

Chen Jiamei, Method of determination on cooling capacity of quenching groove, Heat Treatment of Turbine, 1982(3): 26–29.

Torten, G. E., Bates, C. E., Clinton, N. A., Handbook of quenching technology, ASM International, Cleveland, 1993: 344–346.

Li Qiang, Wang Ge, Present status and trend of development of computer simulation on quenching process, Heat-duty Machinery, 2001(6): 4–7.

Li Qiang, Wang Ge, Computer simulation of the medium in quenching grooves, China-Russia Seminar on Nonequilibrium Phase Transition under Ultra-Conditions, Yanshan University, Qihuangdao, Hebei, P. R. China, 2001, July: 29–31.

Holder, A. W., Bedient, P. B., Dawson, C. N., FLOTRAN, a threedimensional ground water model, with comparisons to analytical solutions and other models, Advances in Water Resources, 2000, 23: 517–530.

Hu Mingjuan, Metal computer simulation of finite length cylindrical part during heating processed and reasonable utilization of energy, Proc. of the 4th Inter. Semi, of I FTH, Beijing, 1993, 40–45.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Li, Q., Wang, G., Chen, N. et al. Computer simulation of flow fields for quenching medium. Chin.Sci.Bull. 48, 739–742 (2003). https://doi.org/10.1007/BF03187043

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF03187043