Abstract

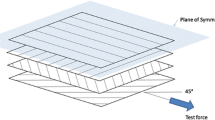

This paper evaluates the fatigue fracture behavior of a chopped strand glass mat/polyester composite both in air and sea water. Bending fatigue (R=−1) was performed on dry and wet specimens, that is respectively in air and sea water. Where the pH concentration of sea water was controlled to 6.0, 8.2, 10.0 and the wet specimens were immersed in the sea waters for 4 months. Throughout the tests, fatigue cracks both in the dry and wet specimens, tested in the air or sea water, occurred at the beginning of the cycle, followed by either of two regions: one decreasing and the other increasing as the crack growth rate increases.

Similar content being viewed by others

References

ASTM D 1141, 1975, “Standard Specification for Substitute Ocean Water.”

ASTM D 570, 1981, “Standard Test Method for Water Absorption of Plastics.”

Dharan, C. K. H., 1975, “Fatigue Failure Mechanisms in a Unidirectionally Reinforced Composite Material,”Fatigue of Composite Material, ASTM STP 569, pp. 171–188.

Hahn, H. T. and Lorenzo, L., 1984,in Advances in Fracture Research, ICF6, New Delhi, India, Pergamon Press, Oxford, Vol. 1, p. 549.

Ishai, O., 1975, “Environmental Effects on Deformation, Strength and Degradation of Unidirectional Glass-Fiber Reinforced Plastics,”Polym. Eng. Sci., Vol. 15, No. 7, pp. 486–490.

JIS K 7119, 1972, “Testing Method of Flexural Fatigue of Rigid Plastics by Plane Bending.”

Kim, Y. J. and Lim, J. K., 1992, “Synthetic Sea Water and Strain Rate Effects on Tensile Properties of E-Glass/Polyester Composites,”Korean Journal of Materials Research, Vol. 2, No. 2, pp. 133–142.

Kim, Y. J. and Lim, J. K., 1997, “A Study on Properties of Corrosion Fracture Surfaces of GFRP in Synthetic Sea Water,”KSME International Journal, Vol. 11, No. 3, pp. 249–254.

Knott, J. F., 1979, Fundamentals of Fracture Mechanics, Tower Press, pp. 246–251.

Kunz, S. C. and Beaumont, P. W. R., 1975. “Microcrack Growth in Graphite Fiber-Epoxy Resin Systems During Compressive Fatigue,”Fatigue of Composite Materials, ASTM STP 569, pp. 71–91.

Milewski, J. V. and Katz, H. S., 1987, “Handbook of Reinforcements for Plastics,” Van Nostrand Reinhold, New York, pp. 267–275.

Price, J. N., 1989, “Stress Corrosion Cracking in Glass Reinforced Composites,”Fractograph and Failure Mechanisms of Polymers and Composites, Elsevier Applied Science, London and New York, pp. 495–531.

Schmitz, G. K. and Metcalfe, A. G., 1966, “Stress Corrosion of E-glass Fibers,”Ind. Eng. Chem., Res & Dev., Vol. 5, No. 1, pp. 1–8.

The Japanese Society of Materials Science, 1980, “Data Book of Resistance of Fatigue Crack Propagation,”The Japanese Society of Materials Science, p. 32.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, Y.J., Lim, J.K. A study on fatigue crack propagation mechanism of GFRP in synthetic sea water. KSME International Journal 15, 1380–1385 (2001). https://doi.org/10.1007/BF03185679

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03185679