Abstract

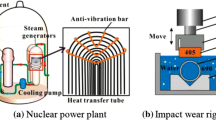

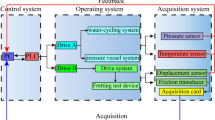

The fretting wear behavior of the contact between Zircaloy-4 tube and Inconel 600, which are used as the fuel rod cladding and grid, respectively, in PWR nuclear power plants was investigated in air. In this study, number of cycles, slip amplitude and normal load were selected as the main factors of fretting wear. The results indicated that wear increased with load, slip amplitude and number of cycles but was affected mainly by the slip amplitude. SEM micrographs revealed the characteristics of fretting wear features on the surface of the specimens such as stick, partial slip and gross slip which depended on the slip amplitude. It was found that fretting wear was caused by the crack generation along the stick-slip boundaries due to the accumulation of plastic flow at small slip amplitudes and by abrasive wear in the entire contact area at high slip amplitudes.

Similar content being viewed by others

References

Cha, J. H., Wambsganss, M. W. and Jendrzejczyk, J. A., 1987, “Experimental Study on Impact/ Fretting Wear in Heat Exchanger Tubes,”ASME Journal of Pressure Vessel Technology, Vol. 109, pp. 265–274.

Cho, K. H., Kim, T. H. and Kim, S. S., 1998, “Fretting Wear Characteristics of Zircaloy-4 Tube,”Wear, Vol. 219, pp. 3–7.

Fisher, N. J., Chow, A. B. and Weckwerth, M. K., 1995, “Experimental Fretting Wear Studies of Steam Generator Materials,”ASME Journal of Pressure Vessel Technology, Vol. 117, pp. 312–320.

Ko, P. L., 1979, “Experimental Studies of Tube Frettings in Steam Generators and Heat Exchangers,”ASME Journal of Pressure Vessel Technology, Vol. 101, pp. 125–133.

Ko, P. L., 1985, “Heat Exchanger Tube Fretting Wear: Review and Application to Design,”ASME Journal of Tribology, Vol. 107, pp. 149–156.

Vingsbo, O., 1988, “On Fretting Maps,”Wear, Vol. 126, pp. 131–147.

Vingsbo, O., Massih, A. R. and Nilsson, S., 1996, “Evaluation of Fretting Damage of Zircaloy Cladding Tubes,”ASME Journal of Tribology, Vol. 118, pp. 705–710.

Waterhouse, R. B., 1975,Fretting Corrosion, Pergamon Press, p. 36.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, TH., Kim, SS. Fretting wear mechanisms of Zircaloy-4 and Inconel 600 contact in air. KSME International Journal 15, 1274–1280 (2001). https://doi.org/10.1007/BF03185668

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03185668