Abstract

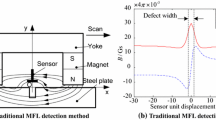

Leakage magnetic flux (LMF) is widely used for non-contact detection of cracks. The combination of optics and LMF offers advantages such as real time inspection, elimination of electrical noise, high spatial resolution, etc. This paper describes a new nondestructive evaluation method based on an original magneto-optical inspection system, which uses a magneto-optical sensor, LMF, and an improved magnetization method. The improved magnetization method has the following characteristics: high observation sensitivity, independence of the crack orientation, and precise transcription of the geometry of a complex crack. The use of vertical magnetization enables the visualization of the length and width of a crack. The inspection system provides the images of the crack, and shows a possibility for the computation of its depth.

Similar content being viewed by others

Abbreviations

- A1 :

-

Approximated area where dc and C4 exist

- Bs :

-

Saturated magnetic induction of the MO sensor

- B z, base :

-

Distribution of the magnetic induction in the non-crack area

- B z, crack :

-

Distribution of the magnetic induction in the crack area

- C1(δ), C2(δ):

-

Coefficients used to express I output as a linear equation of H

- C3 :

-

Constant proportional to the base power of detected light from the non-crack area

- C4 :

-

Constant proportional to the permeability of the specimen and m

- C 04 :

-

Initial approximation of C4

- dc :

-

Depth of the crack

- d 0c :

-

Initial approximation of d

- E:

-

Electric field of the light

- f3 :

-

Measured distribution of Output 1

- f4 :

-

Theoretical distribution of the LMF

- fsum:

-

Sum of the squares of differences between f3 and f4

- H:

-

Intensity of the external magnetic field

- Hs:

-

Magnetic field for saturating the MO sensor

- HZ :

-

Vertical component of LMF

- IMAX :

-

Upper limit of the power of detected light

- IMIN :

-

Lower limit of the power of detected light

- IOUTPUT :

-

Intensity of the reflected light from the MO sensor

- lc :

-

Length of the crack

- m:

-

Magnetic charge per unit area

- n:

-

Total number of points equally spaced on the measurement area

- r0 :

-

Radius of the laser spot

- wc :

-

Width of the crack

- (x,y,z):

-

Location of detection

- Z0 :

-

Lift-off

- σ:

-

Angle between the polarization plane and the analyzer

- θ s :

-

Faraday rotation angle

References

Dennis, J. J. and Woods, D. J,, 1987, “New computing Environments: Microcomputers in Large-Scale Computing”,Society for Industrial and Applied Mathematics.

Fitzpatrick, G. L., Thome, D. K., Skaugset, R. L., Shih, E. Y. C., and L. Shih, W. C., 1993, “Magneto-Optic/Eddy Current Imaging of Aging Aircraft-A New NDI Technique,”Materials Evaluation, Vol. 51, No. 12, pp. 1402–1407.

Ishihara, M., Sakamoto, T., Haruna K., Nakamura, N., Machida, K., and Asaharaara, Y., 1996, “Advanced Magnetic Flux Leakage Testing System Using Magneto-optical Film,”Journal of the Japanese Society for Nondestructive Inspection, Vol. 45, No. 4, pp. 283–289.

Lee, J., and Shoji T., 1998b, “Novel NDI and Analysis of the Crack by use of New Magnetization Method and MO sensor,”Proceedings of The 75th JSME Spring Annual Meeting, pp. 604–605.

Lee, J., and Shoji, T., 1999a, “Development of a NDI System using the Magneto-Optical Method-Development of the Magneto Optical Inspection System,”Journal of the Japanese Society for Non-Destructive Inspection, Vol. 48, No. 3, pp. 165–171.

Lee, J., and Shoji, T., 1999b, “Development of a NDI System using the Magneto-Optical Method-Remote Sensing using the Novel Magneto-Optical Inspection System,”Journal of the Japanese Society for Non-Destructive Inspection, Vol. 48, No, 4, pp. 165–171.

Lee, J., Lee, H., Shoji, T., and Minkov, D., 1998a,Application of Magneto-Optical Method for Inspection of a Tube, IOS Press, Amsterdam, pp. 49–57.

Lee, J., Shoji, T., and Najib, N., 1997, “Development of the Crack Inspection System by use of Laser and Leakage Magnetic Flux,”Proceedings of Symposium on Optical NDT Methods for Surface Flaw Detection, Tokyo, pp. 55–62.

Minkov, D., Lee, J. and Shoji, T., 2000, “Improvement of the Dipole Model of a Surface Crack,”Materials Evaluation (in press).

Mukae, S., Katoh, M. and Nishio, K., 1988, “Investigation of Quantification for Defect and Effect of Factors Affecting Leakage Flux Density in Mangetic Leakage Flux Testing Method”,Journal of the Japanese Society for Non-Destructive Inspection, Vol. 37, No. 11, pp. 885–894

Sato, K., 1994,Optics and Magnetics, Asakurasyoten

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J., Lyu, S. & Nam, Y. An algorithm for the characterization of surface crack by use of dipole model and magneto-optical non-destructive inspection system. KSME International Journal 14, 1072–1080 (2000). https://doi.org/10.1007/BF03185061

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03185061