Abstract

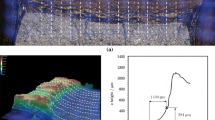

Most research to date concerning the cryogenic toughness of austenitic stainless steels has concentrated on the base metal and weld metal in weldments. The most severe problem faced on the conventional austenitic stainless steel is the thermal aging degradation such as sensitization and carbide induced embrittlement. In this paper, we investigate the cryogenic toughness degradation which can be occurred for austenitic stainless in welding. The test materials are austenitic stainless JN1, JJ1 and JK2 steels, which are materials recently developed for use in nuclear fusion apparatus at cryogenic temperature. The small punch (SP) test was conducted to detect similar isothermally aging condition with material degradation occurred in service welding. The single-specimen unloading compliance method was used to determine toughness degradation caused by thermal aging for austenitic stainless steels. In addition, we have investigated size effect on fracture toughness by using 20% side-grooved 0.5TCT specimens.

Similar content being viewed by others

References

ASTM E 813, 1989, “Standard Test Method for JIC, A Measure of Fracture Toughness,”Annual Book of ASTM Standards.

Horiguchi, K., Shindo, Y., Kobori. T., Takahashi, H., Nakajima, H. and Tsuji. H., 1995, “Cryogenic Fracture Toughness and Temperature Rise of thick Section Weldment in JN1 Forged Plate with Inconel 625 Type Filler Metals,”Proceeding of the 1995 Annual Meeting of JSME/MMD, 95-2(B), pp. 199–200.

Kwon, I. H., 1998, “A Study on Fracture Toughness Degradation in Cryogenic Structural Material Using Single-Specimen Method,”Transactions of the Korea Society of Mechanical Engineers, Vol. 22, No. 2, pp. 343–351.

Kwon, I. H. and Chung. S. H., 1998, “Cryogenic Fracture Behaviors and Polarization Characteristics According to Sensitizing Heat Treatment on Structural Material of the Nuclear Fusion Reactor,”Transactions of the Korea Society of Mechanical Engineers, Vol. 22, No. 2, pp. 311–320.

Lyu, D. Y., Yu, H. S., Chang, W. S., Lim, J. K. and Chung, S. H., 1990, “Fracture Toughness Evaluation of Welded Steel Joint by Small Punch Test,”Proc. of the KSME/JSME Joint Conference, Fracture and Strength ’90, pp. 1482–1487.

Madhava, N. M., and Armstrong, R. W., 1973, “Discontinuous Twining of Titanium at 4. 2K,”Matallurgical Transactions, Vol. 5, pp. 1517–1519.

Mchenry, H. I., and Reed, R. P., 1980, “Structural Alloys for Superconducting Magnets in Fusion Energy Systems,”Nuclear Engineering and Design, Vol. 58, pp. 219–236.

Nakajima, H., Yoshida, K., and Shimamoto, S., 1988, “Round Ribin Tensile and Fracture Test results for an Fe−22Mn−13Cr−5Ni Austenitic Stainless Steel at 4K,”Advances in Cryogenic Engineering (Materials), Vol. 34, pp. 241–249.

Ogawa, T., Koseki, T., Ohkita, S. and Nakajima, H., 1990, “4K Properties of High-Nitrogen Stainless Steel Weldments,”Welding Research Supplement, pp. 205–212.

Akuda, S., Saito, M., Hashida, T. and Takahashi, H., 1991, “Small Punch Testing Method for the Development for Functionally Gradient Materials,”Transactions of the Japan Society of Mechanical Engineers, Vol. 57, No. 536, pp. 940–945.

Reed, R. P. and Simons. N. J., 1984, “Low Temperature Strengthening of Austenitic Stainless Steels with Nitrogen and Carbon,”Advances Cryogenic Engineering Materials, Vol. 30, pp. 127–136.

Saucedo, M. L., Watanabe, Y., Shoji, T. and Takahashi, H., “An Electrochemical Study of Thermal Degradation in Austenitic Stainless Steels,”Proc. of Asian Pacific Conference for Fracture and Strength’96, pp. 837–842.

Shindo, Y., Kobori, T., Horiguchi, K., Yamada, E. Nakajima, H. and Tsuji, H., 1995, “Fracture Toughness and Temperature Rise during Crack Propagation in Forged JJI Type Austenitic Stainless Steel Plate at 4.2K,”Journal of Japan Institute of Metals, Vol. 59, No. 8, pp. 793–798.

Simmons, J. W., Atteridge, D. G. and Rawers., 1994, “Sensitization of High-Nitrogen Austenitic Stainless Steels by Dichromium Nitride Precipitation,”Corrosion, Vol. 50, No. 7, pp. 491–501.

Yoshida, K., Nakajima, H., Oshikiri, M., Tobler, R. L., and Shimamoto, S., 1988, “Mechanical Tests of Large Specimens at 4K: Facilities and Results,”Advances in Cryogenic Engineering (Materials), Vol. 34, pp. 225–232.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kwon, IH., Yu, HS. Cryogenic fracture toughness evaluation for austenitic stainless steels by means of unloading compliance method. KSME International Journal 15, 26–34 (2001). https://doi.org/10.1007/BF03184795

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF03184795