Abstract

Overview of running research activities — Study on the melt flow in the hearth of the iron making blast furnace — Green energy for metals production — Advanced process modelling of hot metal desulphurization by injection of Mg and CaO — Inclusion engineering — High performance casting — Development of the oxygen steelmaking process — Simulation of a continuous steel reheat furnace — Simulation of a mobile heat treatment furnace — Simulation and optimization of phosphorus production

Zusammenfassung

Überblick über die laufenden Forschungsarbeiten — Schmelzfluss im Herd des Eisenhochofens — „Grüne Energie” zur Metallerzeugung — Fortschrittliche Prozessmodellierung der Flüssigmetall-Entphosphorung durch Einblasen von Mg und CaO — Einschlüsse — Hochleistungsgießen — Weiterentwicklung der Sauerstoff-Stahlerzeugung — Simulation eines kontinuierlichen Glühofens — Simulation eines mobilen Glühofens — Simulation und Optimierung der Phosphorerzeugung

Similar content being viewed by others

References

Post, J. R., W. M. Husslage, Y. Yang andM. A. Reuter: The Distributed Nature of Material Properties and Its Effect on Liquid Flow and Mass Transfer in the Blast Furnace Lower Zone. International Blast Furnace Lower Zone Symposium, Australia, 25–27 Nov. 2002, 6–13.

Post, J. R., Y. Yang andM. A. Reuter: Modelling the inhomogeneous dead man of a blast furnace: the population balance model approach. Proceedings of IMPC-2003, XXII International Mineral Processing Congress, Eds. L. Lorenzen and D. J. Bradshaw, Cape Town, 28 September–3 October 2003, 1396–1405.

Post, J. R., T. Peeters, Y. Yang andM. A. Reuter: Hot metal flow in the blast furnace hearth: thermal and carbon dissolution effects on buoyancy, flow and refractory wear. CFD-2003, 3rd International Conference on Computational Fluid Dynamics in the Minerals & Process Industries, Melbourne, 10–12 December 2003.

Post, J. R., D. Tognarelli, J. van der Stel, Y. Yang andM. A. Reuter: Hot Metal flow in the hearth of a blast furnace: Influence of dynamic changes in the dead man porosity due to coke dissolution and coke size changes. Proceedings of the 5th European Iron & Cokemaking Conference, 12–15 June 2005, Stockholm.

Georgalli, G. A., andM. A. Reuter: Modelling the co-ordination number of a packed bed of spheres with distributed sizes using a CT scanner. Minerals Engineering, 2005 (in press).

Visser, H. J., andR. Boom: Proceedings of the 3rd International congress on the science and technology of steelmaking, May 9–12 2005, Charlotte NC, USA. AIST, Warrendale (PA), USA, 369–379.

Tiekink, W. K., R. H. Boertje, R. Boom, B. Deo, W. van der Knoop, R. A. L. Kooter, M. Lee andP. Gelten: Some aspects of the behaviour of calcium in low carbon low silicon aluminium killed steel. Proceedings 13th Instituto Argentino de Siderurgia (IAS), Steelmaking Seminar, 29–31 October and 1 November 2001, Buenos Aires, Argentina, 339–346.

Tiekink, W. K., R. H. Boertje, R. Boom, R. A. L. Kooter andB. Deo: Aspects of CaFe cored wire injection into steel. 86th Steelmaking Proceedings, ISS Conference, 27–30 April 2003, Indianapolis, USA. ISS-AIME, Warrendale (PA), USA, 157–164.

Tiekink, W. K., andR. Boom: Calcium metallurgy of aluminium killed steel. NIMR Conference Building Bridges in Metallurgy, Noordwijkerhout, The Netherlands, 20–21 December 2004.

Kromhout, J. A., V. Ludlow, S. McKay, A. S. Normanton, M. Thalhammer, F. Ors andT. Cimarelli: Physical properties of mould powders for slab casting. Sixth International Conference on Molten Slags, Fluxes and Salts, Stockholm/Helsinki, June 2000. KTH, Division of Metallurgy, Sweden, 2000, ISBN 91-7170-606-2, paper 97.

Kromhout, J. A., andD. W. van der Plas: The melting speed of mould powders, determination and application in casting practice. Sixth International Conference on Molten Slags, Fluxes and Salts, Stockholm/Helsinki, June 2000. KTH, Division of Metallurgy, Sweden, 2000, ISBN 91-7170-606-2, paper 151.

Kromhout, J. A., A. A. Kamperman, M. Kick andJ. Trouw: Mould powder selection for thin slab casting. Seventh International Conference on Molten Slags, Fluxes and Salts, Cape Town, South Africa, January 2004, South African Institute of Mining and Metallurgy, Johannesburg, South Africa, 2004, 731–736.

Cornelissen, M. C. M., J. A. Kromhout andM. Kick: Thin Slab Casting: Growing Towards a High Performance Technology. SMEA Conference and Exhibition — Advances in Secondary Steelmaking and Continuous Casting, Sheffield, June 2004.

Peeters, T. W. J., R. Koldewijn, J. A. Kromhout andA. A. Kamperman: Optimization of an EMBr for a thin-slab caster. 5th European Casting Conference, Nice, June 2005.

Deo, B., andR. Boom: Fundamentals of Steelmaking Metallurgy, Prentice Hall International, London, UK, 1993, ISBN 0-13-345380-4.

Deo, B., S. Gandhi, R. Rastogi, G. van Unen andR. Boom: Theoretical and practical aspects of desulphurization by calcium carbide powder injection in 400 ton torpedoes. Trans. Indian Inst. Met. 48 (1995) 441–446.

Boom, R., A. A. Kamperman, O. Dankert andA. van Veen: Inert argon as active gas: a dangerous double agent. Proceedings of the Belton Memorial Symposium, 10–12 January 2000, Sydney, Australia, ISS-AIME, Warrendale (PA), USA, 53–61.

Boom, R., O. Dankert andA. van Veen: The solubility of argon in liquid steel. Metall. Mater. Trans. 31B (2000), 913–919.

Smith, R. B., R. Boom, M. G. Sexton, Y. de Lassat de Pressigny andR. Steffen: The future for DR and SR; a European perspective. Proceedings 4th European Coke and Ironmaking Congress, Volume 2, ATS, Paris, France, 19–22 June 2000, 703–709.

Boom, R., K. C. Mills andS. Riaz: Recent trends in research on slags. Proceedings 6th International Conference on Molten Slags, Fluxes and Salts, Stockholm, Sweden and Helsinki, Finland, 12–17 June 2000. KTH, Division of Metallurgy, Sweden, 2000, ISBN 91-7170-606-2, paper 110.

Boom, R., K. C. Mills andS. Riaz: Recent trends in research on slags. Ironmaking and Steelmaking, Vol. 27 (2000) 99–102.

Boom, R.: Iron, the hidden element — The role of iron and steel in the twentieth century: 47th Hatfield Lecture, Steel World, Vol. 5 (June 2000) 88–96.

Boom, R. andR. Steffen: Recycling of scrap for high quality steel products. Steel research 72 (2001) 91–97.

Mehmetaj, B., andR. Boom: Ferronickel production in Kosova — Past performance and new opportunities. Steel research 72 (2001) 428–433.

Boom, R.: IJzer, meester der metalen? Inaugural speech, Delft University of Technology, 14th June 2002, Delft University of Technology, 2002, ISBN 90-9016089-2.

Boom, R.: An Intimate Image of the Intermetallic Interface. Proceedings Mills Symposium Metals, Slags, Glasses: High Temperature Properties & Phenomena, 22–23 August 2002, London, UK, EditorsR. E. Aune andS. Sridhar, The Institute of Materials, London, UK, 2002, 219–220.

Graveland-Gisolf, E., P. Mink, A. Overbosch, R. Boom, G. de Gendt andB. Deo: The slag-droplet model for oxygen steelmaking: control of kinetics. Proceedings 11th Japan-Germany Seminar on Fundamentals of Iron and Steelmaking, 17–18 September 2002, Düsseldorf, Verlag Stahleisen, Düsseldorf, Germany, 2002, 35–41.

Boom, R., S. Riaz andK. C. Mills: Slags and fluxes entering the new millennium: an analysis of recent trends in research and development. Proceedings 7th International Conference on Molten Slags, Fluxes and Salts, Cape Town, South Africa, 25–28 January 2004, South African Institute of Mining and Metallurgy, Johannesburg, South Africa, 2004, 1–9.

Boom, R., S. Riaz andK. C. Mills: Slags and fluxes entering the new millennium: an analysis of recent trends in research and development. Ironmaking and Steelmaking, Volume 31, 2004, No. 6, 1–5.

Deo, B., J. Halder, A. B. Snoeijer, A. Overbosch andR. Boom: Effect of MgO and Al2O3 variations in oxygen steelmaking (BOF) slag on slag morphology and phosphorus distribution. Proceedings 7th International Conference on Molten Slags, Fluxes and Salts, Cape Town, South Africa, 25–28 January 2004, South African Institute of Mining and Metallurgy, Johannesburg, South Africa, 2004, 105–111.

Boom, R.: Evolution of process control in fifty years of oxygen steelmaking: the IJmuiden experience. Oxygen in Steelmaking, Proceedings of the International Symposium on Oxygen in Steelmaking, August 22–25, 2004, Hamilton, Ontario, Canada. EditorsG. Irons andS. Sun, The Metallurgical Society of the Canadian Institute of Mining and Metallurgy, Montreal, Quebec, 2004, 161–189.

Pettifor, S., andR. Boom: Novel developments in steelmaking. Scanmet II, Proceedings of the 2nd International Conference on Process Development in Iron and Steelmaking, 6–9 June 2004, MEFOS, Luleå, Sweden, 2004, Volume 1, 9–18.

Deo, B., R. K. Lingamaneni, A. Dey andR. Boom: Strategies for development of process control models for hot metal desulfurization: conventional and Al techniques. Materials and Manufacturing Processes 20 (2005) No. 3, Special Issue on Genetic Algorithms, 2005, Ed. N. Chakraborti, 407–419.

Yang, Y., J. Kroeze andM. A. Reuter: Simulation of slab movement and transient heating in a continuous steel reheat furnace. Progress in Computational Fluid Dynamics. An International Journal (PCFD) Vol. 4, No. 1, 2004, 46–58.

Yang, Y., R. A. de Jong andM. A. Reuter: Simulation of combustion and metal heating in a mobile heat treatment furnace. Multiphase Phenomena and CFD Modelling and Simulation of Engineering Processes. {edEds.}L. Nastac andBen Q. Li, TMS Annual Meeting, March 14–18, 2004 Charlotte, North Carolina. TMS, Warrendale. 429–439.

Yang, Y., R. A. de Jong andM. A. Reuter: Use of CFD in prediction of the performance of a heat treatment furnace. CFD 2005 — Fourth International Conference on Computational Fluid Dynamics in the Oil and Gas, Metallurgical & Process Industries, 6–8 June, 2005, Trondheim, Norway.

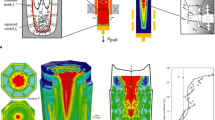

Scheepers, E., Y. Yang, M. A. Reuter andA. T. Adema: A Dynamic-CFD hybrid model of a submerged arc furnace for phosphorus production. Minerals Engineering, 2005 (in press).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Boom, R., Yang, Y. & Xiao, Y. Process metallurgical research activities at Delft University of Technology, Netherlands. Berg Huettenmaenn Monatsh 150, 390–394 (2005). https://doi.org/10.1007/BF03169082

Issue Date:

DOI: https://doi.org/10.1007/BF03169082