Abstract

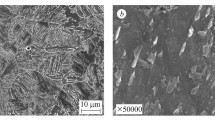

V-notched and fatigue precracked Charpy specimens of various sizes, tested in impact and slow bend, were used to study tempered martensite embrittlement in a 4340 steel. When plotted as a function of tempering temperature, the results showed that the magnitude of the toughness decrease caused by embrittlement varied with the type and size of the specimens. Embrittlement was always detected using thin samples but its detection in thick specimens depended on whether or not they contained a precrack. In particular, no embrittlement-associated fall in toughness was observed using standard size precracked samples tested in slow bend. Separation of the shear and flat fracture components of the absorbed energies showed that the variation of shear energy is a major factor contributing to embrittlement. The results are interpreted as indicating that intergranular fracture occurs more as the result of inhibition of plastic flow within the grains rather than directly as the result of the appearance of a low resistance crack path at the grain boundaries.

Similar content being viewed by others

References

M. Moser:Trans. Am. Soc. Heat Treating, 1925, vol. 7, p. 297.

N. H. Fahey and E. B. Kula:Proc. ASTM, 1963, vol. 63, p. 1147.

C. E. Hartbower and G. M. Orner: Metallurgical Variables Affecting Fracture Toughness in High-Strength Sheet Alloys, Air Force Materials Laboratory Report ASD-TDR-62-868, 1963. AlsoWelding J., 1963, vol. 42, p. 111-S.

M. A. Grossmann:Trans. AIME, 1946, vol. 167, p. 39.

R. L. Rickett and J. M. Hodge:Proc. ASTM, 1951, vol. 51, p. 931.

L. J. Klinger, W. J. Barnett, R. P. Frohmberg, and A. R. Troiano:ASM Trans. Quart., 1954, vol. 46, p. 1557.

L. S. Castleman, B. L. Averbach, and M. Cohen:ASM Trans. Quart., 1952, vol. 44, p. 240.

B. R. Queneau:Embrittlement of Metals, ASM, Cleveland, Ohio, 1956.

B. R. Banerjee: Fracture Micromechanics in High-Strength Steels, Structure and Properties of Ultrahigh-Strength Steels, STP 370, ASTM, Philadelphia, Pa., 1963.

R. Raring: Load-Deflection Relationships in Slow-Bend Tests of Charpy V-Notch Specimens,Proc. ASTM, 1952, vol. 52, p. 1034.

G. M. Orner and C. E. Hartbower:Welding J., 1960, vol. 39, p. 147-S.

G. M. Orner and C. E. Hartbower:Welding J., 1961, vol. 40, p. 405-S.

A. J. Baker, F. J. Lauta, and R. P. Wei: Relationships Between Microstructure and Toughness in Quenched and Tempered Ultrahigh-Strength Steels, Structure and Properties of Ultrahigh-Strength Steels, STP 370, ASTM, Philadelphia, Pa., 1963.

R. P. Wei: Fracture Toughness Testing in Alloy Development, Fracture Toughness Testing and Its Applications, STP 381, ASTM, Philadelphia, Pa., 1964, p. 279.

F. J. Lauta and E. A. Steigerwald: Influence of Work Hardening Coefficient on Crack Propagation in High-Strength Steels, Air Force Materials Laboratory Report AFML-TR-65-31, 1965.

E. B. Kula and A. A. Anctil: Tempered Martensite Embrittlement and Fracture Toughness in 4340 Steel, Watertown Arsenal Report AMRA TR 67-03, 1967.

W. J. Harris, J. A. Rinebolt, and R. Raring:Welding J., 1951, vol. 30, p. 417-S.

C. E. Hartbower:Welding J., 1957, vol. 36, p. 494-S.

C. E. Hartbower:Proc. ASTM, 1956, vol. 56, p. 521.

C. Wells and W. B. Triplett: Energy of Crack Formation and Crack Propagation Under Impact, Progress Reports on Air Force Materials Laboratory Contract AF33(616)-5830, 1960.

J. D. Lubahn:Welding J., 1955, vol. 34, p. 518-S.

J. D. Lubahn:Welding J., 1956, vol. 35, p. 557-S.

C. A. Griffis and J. W. Spretnak: An Analysis of the Energy Absorption and Fracture Process in Conventional Notched Bars of AISI 4340 Steel as a Function of Tensile Strength, Air Force Materials Laboratory Report AFML-TR-69-104, 1969.

J. M. Capus:J. Iron Steel Inst., 1963, vol. 201, p. 53.

J. H. Bucher, G. W. Powell, and J. W. Spretnak:A Micro-Fractographic Analysis of Fracture Surfaces in Some Ultrahigh-Strength Steels, Application of Fracture Toughness Parameters to Structural Materials, p. 323, ed. H. D. Greenberg, Gordon and Breach, N. Y., 1966.

B. S. Lement, B. L. Averbach, and M. Cohen:ASM Trans. Quart., 1954, vol. 46, p. 851.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ronald, T.M.F. The relation between the fracture behavior of 4340 bend specimens and the observation of tempered martensite embrittlement. Metall Trans 1, 2583–2592 (1970). https://doi.org/10.1007/BF03038388

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF03038388