Abstract

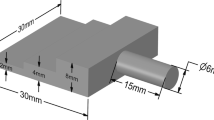

Hard alpha inclusions in titanium (Ti) investment castings are generally known to have detrimental effects on the mechanical properties of these castings. However, actual inclusions are infrequent and occur in random locations in castings. As a result, it is difficult to obtain tensile or fatigue test specimens of titanium castings with inclusions in the gage section. Quantifying the adverse influence of inclusions on the mechanical properties of castings is, therefore, extremely challenging. To address this problem, a novel artificial inclusion seeding methodology was developed to emulate actual Ti investment casting inclusions. Prefabricated inclusions were seeded into machined holes in cast Ti−6Al−4V plates, the holes were back-filled with plugs of the same Ti alloy and were then electron-beam (EB) welded closed. Hot isostatic pressing (HIP) was utilized to incorporate the inclusions fully into the cast titanium material. Finally, the plates were machined to create mechanical test specimens with inclusions centered in the gage region. Test specimens created by means of this novel artificial seeding methodology were evaluated and found to be equivalent to Ti casting specimens containing actual cast-in inclusions.

Similar content being viewed by others

References

M. Donachie,Titanium, A Technical Guide, ASM Int., Metals Park, Ohio, USA (1988).

S. Watakabe, K. Suzuki, and K. Nishikawa,ISIJ Int. 32, 145 (1992).

D. Eylon,Proc. 2 nd Japan Int. Sample Symp., p. 351, Makuhari, Japan (1993).

F. Froes and C. Suryanarayana,Physical Metallurgy and Processing of Intermetallic Compounds, p. 197, Chapmand and Hall, Inc. NY (1996).

K. Suzuki and M. Yao,Met. Mater.-Int. 10, 1 (2004).

D. Lee,Met. Mater.-Int. 11, 4 (2005).

B. Choi, J. Liang, and W. Gao,Met. Mater.-Int. 11, 6 (2005).

C. Shamblen and G. Hunter,Proc. of the 1989 Vacuum Metallurgy Conf. on the Melting and Processing of Specialty Materials, Pittsburgh, PA p. 6, (1989).

J.D. Cotton, L.P. Clark, T.R. Reinhart, and W. Spear,AIAA-2000-1464, American Institute of Aeronautics and Astronautics, p. 4, (2000).

Military Handbook,General Guidelines for Aircraft Structural Integrity Program (ASIP), MIL-HDBK-1530A, (2002).

National Transportation Safety Board (NTSB)Accident Report No: PB90-910406 NTSB/AAR 90-06 (1990).

United States Air Force,Proprietary Program History (2002)

AMS 4962,Aerospace Materials Specification 4962, Society of Automotive Engineers (1998).

WPAFB,Materials and manufacturing Directorate, Mechanical Data, Air Force Research Lab., Materials and Manufacturing Directorate, Design Data Group, Wright Patterson Air Force Base, Ohio, U.S.A. (2001).

D.C. Montgomery,Design and Analysis of Experiments, 2 nd ed, p. 21–28, John Wiley and Sons, New York (1984).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ret, P.L., Brevick, J.R. & Park, Y.K. Development and evaluation of a novel inclusion seeding methodology for Ti−6Al−4V castings. Met. Mater. Int. 13, 285–292 (2007). https://doi.org/10.1007/BF03027884

Issue Date:

DOI: https://doi.org/10.1007/BF03027884