Abstract

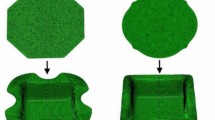

This study defined the cross-section consisting of a round in the major axis and a straight line in the minor axis for deep drawing product as elliptical. A process sequence design for elliptical-shaped deep drawing products was diversely proposed according to shape, dimension, and specification of products. This study presents two approaches to the design of a preform, a key process for elliptical-shaped products: using a punch with a circular cross-section, and for geometrical similarity of the intermediate process cup and final product, using a punch with a cross-section similar to that of the oval-shaped cup. In addition, blank shapes for elliptical-shaped products were designed and verified with experimental results. In the study, production rules, which play important roles in an automated process sequence design system, based on two approaches mentioned above and blank design, were generated for elliptical-shaped deep drawing products. The system developed on the production rules consists of a recognition module of input geometry, 3-D modeling to calculate surface area automatically, blank design, and a process planning module. Improving productivity and reducing time and cost would prove to be very useful.

Similar content being viewed by others

References

T. C. Chang,Expert Process Planning for Manufacturing, Addison-Wesley, New York (1990).

B. Gopalakrishnan and V. Pandiarajan,J. Mater. Proc. Tech. 28, 93 (1991).

S. B. Park, Y. Choi, B. M. Kim and J. C. Choi,J. Mater. Proc. Tech. 75, 17 (1998).

G. Eshel, M. Barash and W. Johnson.Int. J. Mech. Work. Tech. 14, 1 (1986).

S. K. Sitaraman, G. L. Kinzel and T. Altan,J. Mater. Proc. Tech. 25, 247 (1991).

S. K. Esche, S. Khamitkar, G. L. Kinzel and T. Altan,J. Mater. Proc. Tech. 59, 24 (1996).

M. Tisza,J. Mater. Proc. Tech. 53, 423 (1995).

G. Perrotti, E. Maggiorano, F. Spirito and S. Tomincasa,Annals of the CIRP 34, 236 (1985).

C. H. Toh, S. Kobayashi,Int. J. Mach. Tool Des. Res. 25, 15 (1985).

S. H. Park, J. W. Yoon, D. Y. Yang and Y. H. Kim,Int. J. Mech. Sci. 41, 1217 (1999).

N. S. Kim and S. Kobayashi,Int. J. Mach. Tool. Des. Res. 26, 125 (1986).

T. Kuwabara and W. H. Si,J. Mater. Proc. Tech. 63, 89 (1997).

S. A. Majlessi and D. Lee,J. Engineering for Industry 115, 110 (1993).

N. Kawai, T. Mori, H. Hayashi and F. Kondoh,J. Engineering for Industry 109, 355 (1987).

M. M. Moshksar and A. Zamanian,J. Mater. Proc. Tech. 72, 363 (1997).

D. H. Park, W. R. Bae and S. S. Kang,Key Eng. Mater. 177, 523 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kang, S.S., Park, D.H., Choi, B.K. et al. Development of an automated process sequence design system for multistage elliptical-Shaped deep drawing products. Met. Mater. Int. 7, 133–142 (2001). https://doi.org/10.1007/BF03026951

Issue Date:

DOI: https://doi.org/10.1007/BF03026951