Abstract

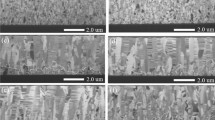

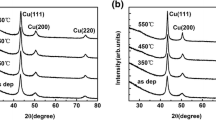

Cu is now widely accepted as the premier replacement for Al in ULSI interconnect metalliztion. However, it cannot be used without a diffusion barrier since it diffuses through a SiO2 layer into the Si substrate very easily. TiN is one of the potential candidates for the barrier. In this paper the properties of the Cu films deposited on four different kinds of TiN films were compared. The properties of the CVD-Cu film strongly depend upon the type of the TiN substrate. The Cu film with the highest quality from the viewpoint of surface roughness and thickness uniformity on the four different kinds of the TiN substrate are obtained at 180, 220, 200°C and 200°C for the TiN(TDEAT), TiN(TDEAT+NH3), TiN(TDMAT), and TiN (sputtered) substrates, respectively. The Cu deposition temperatures at which the Cu films with the lowest electrical resistivity are deposited 200°C on TiN(TDEAT), at 220°C on TiN(TDEAT+NH3) and TiN(TDEAT) and 180°C on TiN(sputtered), respectively. The smoothest and flattest surface morphology of the Cu film is obtained on TiN(TDMAT), the next on TiN(TDEAT), the third on TiN(sputtered), and the last on TiN(TDEAT+NH3) as a descending order at the Cu deposition temperatures of 200°C.

Similar content being viewed by others

References

“Handhook of Thin Film Technology ”, edited by L. Maissel and R. Glang, Mc Grawhill Book Co., p. 62, (1983).

J. Li. Y. Shacham-Diamond and J. W. Mayer, Mater. Sci. Rep., 9 (1992) p. 1.

N. Yokoyama, K. Hinode and Y. Homma, “LPCVD Titanium Nitride for ULSIs”, J. Electrochem. Soc.,138, 190 (1991).

M. Wittmer, “Properties and Microelectronic Applications of Thin Films of Refractory metal Nitrides”, J. Vac. Sci. Techno.,A-3, 1797 (1985).

R. Nast and W. -H. Lepel, Chem. Ber.102, p. 3324 (1969).

I. J. Raaijmakers, R. N. Vrtis, G. S. Sandhy, J. Yang, E. K. Broadbent, D. A. Roberts and A. Lagendijk, “Conformai Deposition of TiN at Low Temperature by Metal Organic CVD”, Proceedings of the 9th International VLSI Multilevel Interconnection Conference, p. 260, (1992).

Jaeho Kim, Jaegab Lee, Choongsoo Chi, Sangjoon Park, Changsu Kim and Eungu Lee, “Effect of Carrier gas (N 2,He) on MOCVD TiN Formation”, Korean J. Mat. Res.,6(4), 388 (1996).

A. Intemann, H. Koerner and F. Koch, “Film Properties of CVD Titanium Nitride Deposited with Organometallic Precursors at Low Pressure Using Inert Gases, Ammonia, or Remote Activation”, J. Electrochem. Soc.,140, 3215 (1993).

K. A. Littau, M. Eizenberg, S. Ghanayem. H. Tran, Y. Maeda, A. Sinha, M. Chang, G. Dixit, M. K. Jain, M. F. Chrisholm and R. H. Haveman, “CVD TiN: A Barrier Metallization for Sub-Micron Via and Contact Applications”, Proceedings of the 11th International VLSI Multilevel Interconnection Conference, p. 246, (1992).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Shin, Y.H., Lee, C. Comparison of the properties of Cu films deposited on four different types of TiN substrates. Metals and Materials 3, 108–112 (1997). https://doi.org/10.1007/BF03026133

Issue Date:

DOI: https://doi.org/10.1007/BF03026133