Abstract

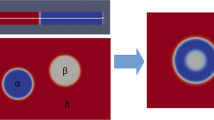

Morphological evolution of coherent precipitates under an applied stress is analyzed by means of a discrete atom method, which is predicated upon Hookean atomic interactions and Monte Carlo diffusion, and mates no assumption of a specific shape. Precipitates having elastic constants different from those of the matrix phase art treated in dislocation-free, anisotropic elastic systems under a plane strain condition with a purely dilatational misfit. Under an applied tensile stress, soft particles with a positive misfit strain tend to become plates perpendicular to the applied stress axis, while hard particles elongate along the stress direction. If the elastic interaction between the applied stress and the coherency strain is strong enough, precipitates often split into smaller particles and then follow coarsening. Even in the absence of a coherency strain, particles are shown to undergo morphological evolution through Eshelby’s inhomogeneity effects. A particle shape depends on the following variables: the sign and magnitude of the coherency strain, the sense and magnitude of the applied stress, its stiffness relative to the matrix phase, and the magnitude of the interfacial energy.

Similar content being viewed by others

References

J. D. Eshelby,Prog. Solid Mech. 2, 89 (1961).

J. K. Lee, D. M. Barnett, and H. I. Aaronson,Metall. Trans. 8A, 963 (1977).

T. Mura,Micromechanics of Defects in Solids, 2nd ed., p. 177, Martinus Nijhoff, Dordrecht (1987).

A. G. Khachaturyan,Theory of Structural Transformations in Solids, p. 213, Wiley & Son, New York (1983).

Y. Wang, L. Q. Chen and A. G. Khachaturyan, inSolid to Solid Phase Transformations (eds., W. C. Johnson et al.) p. 245, TMS, Warrendale, PA (1994).

Y. Wang, L. Q. Chen and A. G. Khachaturyan,Acta Metall. 41, 279 (1993).

M. E. Thompson, C. S. Su and P. W. Voorhees,Acta Metall. 42, 2107 (1994).

Z. A. Moschovidis and T. Mura,J. Appl. Mech. 42, 847 (1975).

S. Satoh and W. C. Johnson,Metall. Trans. 23A, 2761 (1992).

J. Gayda and D. J. Srolovitz,Acta Metall. 37, 641 (1989).

J. K. Lee,Metail. Trans. 22A, 1197 (1991).

J. K. Lee,Scripta Metall. 32, 559 (1995).

J. K. Lee,Metail. Trans. 27A, 1449 (1996).

J. K. Tien and S. M. Copley,Metall. Trans. 2, 215 (1971).

T. Miyazaki, K. Nakamura and H. Mori,J. Mater. Sci. 14, 1827 (1979).

W. F. Hosford and S. P. Agrawal,Metall Trans. 6A, 487 (1975).

B. Skrotzki, E. A. Starke, Jr., and G. J. Shiflet, inMicrostructures and Mechanical Properties of Aging Materials (eds., P. K. Liaw et al.) TMS, Warrendale, PA, in press.

A. Pineau,Acta Metall. 24, 559 (1976).

J. K. Lee and W. C. Johnson, inSolid to Solid Phase Transformations (eds., H. I. Aaronson et al.) p. 127, TMS, Warrendale, PA (1982).

W. C. Johnson, M. B. Berkenpas and D. E. Laughlin,Acta Metall. 36, 3149 (1988).

W. Hort and W. C. Johnson,Metall. Trans. 27A, 1561 (1996).

W. G. Hoover, W. T. Ashurst, and R. J. Olness,J. Chem. Phys. 60, 4043 (1974).

K. Binder. Monte Carlo Methods, p. 1, Springer-Verlag, New York (1979).

J. K. Lee, inPhase Transformations during the Thermal/Mechanical Processing of Steel (eds., E. B. Hawbolt and S, Yue) p 49, The Metallurgical Society of CIM, Montreal, Quebec (1995).

J. K. Lee, inMicromechanics of Advanced Materials (eds., S. N. G. Chu et al.) p. 41, TMS, Warrendale, PA (1995).

R. W. Little,Elasticity, p. 87, Prentice-Hall, Englewood Cliffs, NJ (1973).

J. M. Howe and D. A. Smith,Acta Metall. 40, 2343 (1992).

J. K. Lee and H. I. Aaronson,Acta Metall 23, 799 (1975).

H. I. Aaronson and C. Wells,Trans. AIME,206, 1216 (1956).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, J.K. Effects of applied stress on coherent precipitates via a discrete atom method. Metals and Materials 2, 183–193 (1996). https://doi.org/10.1007/BF03026093

Issue Date:

DOI: https://doi.org/10.1007/BF03026093