Abstract

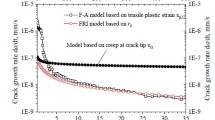

Nickel-based superalloys exhibit sustained load crack growth at elevated temperatures, which significantly contributes to the total fatigue crack growth rate when Kmax is above the threshold value for sustained load cracking, KIEAC. Two empirical curve fitting models, the MSE model and SINH model, have been developed for describing the constants in the crack growth rate equations as a function of the cycling variables for nickel-based superalloys at elevated temperatures. It has been demonstrated that the superposition approach with MSE or SINH fitting was particularly powerful to predict fatigue crack growth rates for nickel-based superalloys at temperatures above 500°C.

Similar content being viewed by others

References

T. Nicholas, G. T. Haritos and J. R. Christoff,AIAA J. Propulsion and Power 1, 131 (1985).

R. H. Van Stone, O. G. Gooden and D. D. Krueger, “Advanced Cumulative Damage Modeling”,Final Report, AFWAL-TR-88-4146, Wright-Patterson Air Force Base, OH (1988).

J. M. Larsen and T. Nicholas, “Cumulative Damage Modeling of Fatigue Crack Growth”,Conference Proceedings, AGARD Advisory Group for Aerospace Research and Development, No. 368, NATO (1987).

T. Nicholas, T. Weerassoriya and N. E. Ashbaugh, inFracture Mechanics, ASTM STP 905 (eds., J. H. Underwoodet al.), p. 167, ASTM, Philadelphia, PA (1986).

D. A. Utah,Air Force Wright Aeronautical Laboratories Report, AFWAL-TR-80-4098, Accession No. ADA 093992 (1980).

M. L. Heil, “Crack Growth in Alloy 718 Under Thermal-Mechanical Cycling”,Ph. D. Dissertation, Air Force Institute of Technology, Wright-Patterson AFB, OH, Dec. (1986).

G. K. Haritos, T. Nicholas and G. O. Painter, inFracture Mechanics, Eighteenth Symposium, ASTM STP 945 (eds., D. T. Read and R. P. Reed), p. 206, ASTM, Philadelphia, PA (1988).

R. P. Gangloff, inProc. of Sagamore Army Materials Research Conference on Corrosion Prevention and Control 33 (eds., M. Levy and S. Isserow), p. 64, U.S. Army Materials Technology Laboratory, Watertown, MA (1987).

T. Nicholas and T. Weerassoriya, inFracture Mechanics, ASTM STP 905 (eds., J. H. Underwoodet al.), p. 155, ASTM, Philadelphia, PA (1986).

W. Dietzel,et al., “Recommendations for Stress Corrosion Testing Using Precracked Specimens”,Document EISI P4-92D, First Draft, Committed 10, European Structural Integrity Society, London April (1992).

W. Dietzel, K. H. Schwalbe and D. Wu, “Application of Fracture Mechanics Techniques to the Environmentally Assisted Cracking of Aluminum 2024”, inFatigue and Fracture of Engineering Materials and Structures 12, 495 (1989).

R. A. Mayville, T. J. Warren and P. D. Hilton, “Crack Velocity-KI Relationship for AISI 4340 in Seawater Under Fixed and Rising Displacement”, inFracture Mechanics: Perspectives and Directions, ASTM STP 1020 (eds., R. P. Wei and R. P. Gangloff), p. 605, ASTM, Philadelphia, PA (1989).

C. R. Saffet al., “Damage Tolerance Analysis for Manned Hypervelocity Vehicles”,First through Fifth Interim technical Reports, No. F33615-88-C-3208, McDonnell Aircraft Company, St. Louis, MO (1986 through 1988),

M. O. Speidel, inStress Corrosion Cracking and Hydrogen Embrittlement of Iron Based Alloys (eds., J. Hochmann, J. Slater, R. D. McCright and R. W. Staehle), p. 1071, NACE, Houston, TX (1977).

R. J. Walter, J. D. Frandsen and R. P. Jewett, inHydrogen Effects in Metals (eds., I. M. Bernstein and A. W. Thompson), p. 819, TMS-AIME, Warrendale, PA (1981).

R. J. Walter and W. T. Chandler, “Effect of High Pressure Hydrogen on IN 718 at-260°F”,Rocketdyne Report, No. RR-70-3/QNO79953 (1970).

R. P. Wei and J. D. Landes,Mat. Res. Stds. 9, 25 (1969).

P. M. Scott, inCorrosion Fatigue: Mechanics, Metallurgy, Electrochemistry and Engineering, ASTM STP 801 (eds., T.W. Crooker and B.N. Leis), p. 319, ASTM, Philadelphia, PA (1983).

I. M. Austen, W. J. Rudd and E. F. Walker, inProc. of the International Conference on Steel in Marine Structures, Comptoir des Produits Siderugiques, Paris, Paper ST 5.4 (1981).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, S.S., Choe, S.J. & Shin, K.S. Quantitative models on corrosion fatigue crack growth rates in metals: Part II. application of fatigue crack growth rate modeling for nickel-based superalloys at elevated temperatures. Metals and Materials 4, 15–23 (1998). https://doi.org/10.1007/BF03026060

Issue Date:

DOI: https://doi.org/10.1007/BF03026060