Abstract

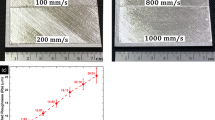

A basic reseach of tailored blank welding between a low carbon steel sheet and a STS 304 stainless steel sheet was carried out with CO2 laser beam. The materials used in this work were a low carbon steel sheet with a thickness of 0.9 mm and a STS 304 stainless steel sheet with the same thickness. Experiments were carried out by applying the Taguchi method to obtain optimized conditions in order to apply this tailored blank laser welding method in the practical manufacturing process. In order to compare the laser welding results with the conventional welding process, GTA welding was carried out for the same materials. Optical microscopy, SEM and XRD analyses were performed to observe the microstructures and to analyze the various phases. A tensile test, hardness test and Erichsen test were performed to evaluate the formability of welded specimens. In addition, immersion test was carried to estimate corrosion resistance. A WDS analysis showed that laser welding resulted in almost the same dilution of both low carbon steel and stainless steel in welded metal, meanwhile, GTA welding resulted in more dilution of stainless steel due to its slower heat conductivity. The formability of the laser welded specimen reached 83% of that in base metal. On the other hand, it was 63% in the case of GTA welding. During the tension test, base metal was fractured in the case of a laser welded specimen, meanwhile the welded zone was fractured in the case of the GTA welded specimen. The corrosion test showed that weight loss per unit area was less in the laser welded specimen than that of the GTA welded specimen.

Similar content being viewed by others

References

J.-C. Mombo-Caristan, V. Lobring, W. Prange and A. Frings inThe Industrial Laser Handbook, 1992-1993 Edition (eds., D. Belforte and M. Levitt). p. 89, Springer-Verlag, New York (1992).

R. H. Lochner and J. E. Matat,Designing for Quality, Quality Resources (1990).

G. S. Peace,Taguchi Method, Addison-Wesley, New York (1993).

S. H. Park,Quality Engineering, Minyoungsa, Seoul (1993).

J. H. Suh, T. H. Kim, B. K. Yu and K. D. Lee,Metals and Materials 4, 157 (1998).

V. P. Kujanpaa,J. of LaserAppl. 2, 24 (1990).

N. Suutala, T. Takalo and T. Moisio,Metall. Trans. 11A, 717 (1980).

S. Kou,Welding Metallurgy, John Wiley & Sons, New York (1987).

Y. Nakao,Weld. Int. 7, 619 (1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Park, J.H., Kim, T.H. Tailored blank welding between low carbon steel sheet and STS 304 stainless steel sheet by CO2 laser beam. Metals and Materials 5, 55–62 (1999). https://doi.org/10.1007/BF03026005

Issue Date:

DOI: https://doi.org/10.1007/BF03026005