Abstract

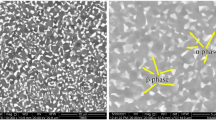

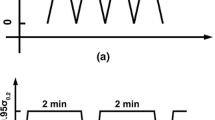

The multiple-sloped relationship between da/dN and AK in stage II fatigue crack propagation regime in most engineering alloys has been a subject of considerable research efforts. Even though the crack closure is recognized as a crucial factor affecting FCP rates, closure effect on transition behavior is often ignored due to the uncertainties associated with ΔKeff value and the difficulties in measuring closure especially in aqueous environment. The present study therefore focused on the closure-free transition behavior in mill annealed Ti-6A1-4V in moist air and 1% NaCl at a fixed potential of -500 mVSCE as a function ofR ratio. The complex da/dN-ΔK relationship in Ti-6A1-4V remains after closure-correction for eachR ratio and environment, suggesting that closure is not a controlling factor for a transition, while it may complicate transition behavior. After closure-correction, the transition points and slopes are insensitive to R ratio in moist air, suggesting that R ratio effect on transition behavior in moist air is mostly due to crack closure. The 1% NaCl solution further complicates the da/dN-ΔKeff shape in Ti-6A1-4V at R ratios of 0.1 and 0.4 by superimposing cyclic stress corrosion cracking (SCC)-induced transition at intermediate ΔK regime. Varying R ratio in 1% NaCl is complex and appears to modify the cyclic and/or static SCC contribution.

Similar content being viewed by others

References

R. S. Piascik and R. P. Gangloff,Metall. Trans. A.,22A, 2415 (1990).

R. S. Piascik and R. P. Gangloff,Metall. Trans. A.,24A, 2751 (1993).

J. A. Feeney, J. C. McMillan and R. P. Wei,Metall. Trans. A.,1, 1741 (1970).

G. R. Yoder, L. A. Cooley and T. W. Crooker,Scripta Metall. 16, 1021 (1982).

R. J. H. Wanhill and L. Schra,“Corrosion Fatigue Crack Arrest in Aluminum Alloys”, Report NLR-TR-87128-U, National Aerospace Laboratory, Netherlands (1987).

G. R. Yoder, L. A. Cooley and T. W. Crooker,Metall. Trans. A.,8A, 1737(1977).

G. R. Yoder, F. H. Froes and D. Eylon,Metall. Trans. A.,15A, 183 (1984).

P. E. Irving and C. J. Beevers,Metall. Trans. 5, 391 (1974).

S. B. Chakrabortty and E. A. Starke, Jr.,Metall Trans. A.,10A, 1901 (1979).

D. B. Dawson and R. M. Pelloux,Metall. Trans. A.,5A, 723 (1974).

R. J. Bucci, Ph.D. Dissertation, Lehigh University, Bethlehem, PA (1970).

D. A. Meyn,Metall. Trans. 2, 853 (1971).

R. J. Walter, J. D. Frandsen and R. P. Jewett, inHydrogen Effects in Metals (eds., L M. Berstein and A. W. Thompson), p. 819, TMS-AIME, Warrendale PA (1981).

M. O. Speidel, inStress Corrosion Cracking and Hydrogen Embrittlement of Iron Based Alloys (eds., J. Hochmann, J. Slater, R.D. McCright and R.W. Stachle), p. 1071, NACE, Houston, TX (1977).

K. S. Chan,Metall. Trans. A.,24A, 2473 (1993).

P. C. Paris, M. P. Gomez and W. E. Anderson,The Trend in Engineering, Washington State Univ.,13, No. 1, 9(1961).

R. G. Forman, V. Shivakumar, J. C. Newman, Jr., S. M. Piotrowski and L. C. Williams, inFracture Mechanics: Eighteenth Symposium, p. 281, ASTM STP 945, ASTM, Philadelphia, PA (1988).

H. J. Gudladt and J. Petit,Scripta Metall. 25, 2507 (1991).

R. O. Ritchie,Intl. Metall. Rev. 20, 205 (1979).

Mechanics of Fatigue Crack Closure, (eds., J. C. Newman and W. Elber), ASTM STP 982, ASTM, Philadelphia, PA (1988).

J. Petit, inTheoretical Concepts and Numerical Analysis of Fatigue, in print.

D. C. Slavik, C. P. Blankenship, Jr., E. A. Starke, Jr. and R. P. Gangloff,Metall. Trans. A,24A, 1807 (1993).

D. C. Slavik, Ph.D. Dissertation, University of Virginia, Charlottesvilie, VA (1993).

T. T. Shih and R. P. Wei,Engr. Frac. Mech. 6, 19 (1974).

M. O. Speidel, M. J. Blackburn, T. R. Beck and J. A. Feeney, inCorrosion Fatigue: Chemistry, Mechanics and Microstructure (eds., O. Devereux, A. J. McEvily and R. W. Staehle), p. 324, NACE, Houston, TX (1972).

M. D. Halliday and C. J. Beevers,Intl. J. Fracture,15, R27(1979).

A. J. McEvily,Atlas of Stress-Corrosion and Corrosion Fatigue Curves, ASM International, Metals Park, OH (1990).

R. P. Gangloff, inEnvironment Induced Cracking of Metals (eds., R. P. Gangloff and M.B. Ives), p. 55, NACE, Houston, TX(1990).

J. C. Newman, Jr.,Intl. J. Fracture 24, No. 3, R131 (1984).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, SS., Rhee, MH. & Lee, CS. Environment and R-ratio effects on fatigue crack propagation transitions in Ti-6A1-4V (ELI). Metals and Materials 2, 37–47 (1996). https://doi.org/10.1007/BF03025945

Issue Date:

DOI: https://doi.org/10.1007/BF03025945