Abstract

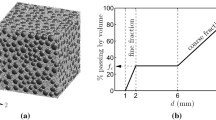

In the process of particle settling in a dilute, a density graded distribution of the liquid below the suspension needs to be designed according to the gravity of the suspension prior to sedimentation. In the present paper a compositionally graded W-Mo composite was formed via the settling of the W and Mo particles, with a density gradient distributed in the initial clear liquid along the settling direction.

Similar content being viewed by others

References

T Jüngling, J Bronback and B Kieback. Ceramic-Metal Functional Gradient Materials by Sedimentation In: B. Ilschner, N. Cherradi, 3rdInternational Symposium on Structural and Functional Gradient Materials, Switzerland: 1994: 161–166

G Kapelski, A Varloteaux. A Technique of Elaboration of Functionally Graded Cermets.Material Science Forum, 1999, 308-311: 175–180

Z Yang, L Zhang and Q Shen. Development of Mathematical Model on Preparation of Functionally Graded Material by Co-sedimentation.J. Mater. Sci. Technol., 2001, 17(2): 275–277

H Xiong, L Zhang and R Yuan. Densification of W-Ni-Cu and W-Ni-Fe Alloys at 1573K.J. Mater. Sci. Techn., 1999, 15: 94–96

H Xiong, L Zhang, L Chen and R Yuan. Design and Fabrication of W-Mo-Ti-TiAl-Al Functionally Graded Material.Metallurgical and Materials Transactions, 2000, 31A: 2369–75

L M Barker and D D Scott. Development of a High-pressure Quasi-isen tipic Plane Wave Generating Capability. SAND, 84-0432

H La and S Tong (translated).Measurement of Particle Size. Beijing: Chinese Building Industry Press, 1984: 232–240

J Huang, J Zhao, J Li, K Akira and W Ryuzo. Fabrication of Metal/ceramic Functionally Graded Materials with Continuous Gradient Composition by Co-sedimentation.China Science Bulletin, 1998, 43(5): 550–554 (in Chinese)

F Tian, Z Yang and L Zhang. Fabrication of Ti-Mo Functionally Graded Materials with a Specific Structure by Co-sedimentaiton.J. Wuhan Univ. Technol., 2000, 23(6): 1–4. (in Chinese)

G Kapelski and A Varloteaux. Role of Elaboration Parameters on the Porosity Fraction of Alumina Graded Performs.Ceramic Transactions, 2000, 114: 397–405

Author information

Authors and Affiliations

Corresponding author

Additional information

Sponsored by the National Natural Science Foundation of China under grant No. 50171049 and the Key Fund of Education Ministry of China under the grant 1999049702.

Rights and permissions

About this article

Cite this article

Yang, Zm., Gong, Dr. & Zhang, Lm. Design of co-sedimentation experiments used to fabricate functionally graded materials with a continuous change of composition. Journal of Wuhan University of Technology-Mater. Sci. Ed. 19, 11–13 (2004). https://doi.org/10.1007/BF03000157

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF03000157