Abstract

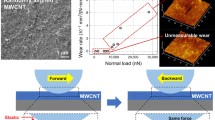

The mechanical as well as tribological characteristics of coating films as thin as a few nm become more crucial as applications in micro-systems grow. Especially, the amorphous carbon film has a potential to be used as a protective layer for micro-systems. In this work, quantitative evaluation of nano-indentation, scratching, and wear tests were performed on the 7nm thick amorphous carbon film using an Atomic Force Microscope (AFM). It was shown that AFM-based nano-indentation using a diamond coated tip can be feasibly utilized for mechanical characterization of ultra-thin films. Also, it was found that the critical load where the failure of the carbon film occurred was about 18μN by the ramp load scratch test. Finally, the wear experimental results showed that the quantitative wear rate of the carbon film ranged 10-9~10-8 mm3/N cycle. These experimental methods can be effectively utilized for a better understanding the mechanical and tribological characteristics at the nano-scale.

Similar content being viewed by others

References

Angus, J. C. and Hayman, C. C., 1988, “Low Pressure Metastable Growth of Diamond and Diamond Like Phase,”Science, Vol. 241, pp. 913- 921.

Bellido-Gonzalez, V., Stefanopoulos, N., and Deguilhen, F., 1995, “Friction Monitored Scratch Adhesion Testing,”Surface and Coatings Technology, Vol. 74–75, pp. 884–889.

Bogdanovic, G., Meurk, A., and Rutland, M. W., 2000, “Tip Friction-Torsional Spring Constant Determination,”Colloids and Surfaces B, Vol. 19, pp. 397–405.

Bhushan, B. and Koinkar, V. N., 1994, “Nanoindentation Hardness Measurements using Atomic Force Microscopy,”Applied Physics Letters, Vol.64, pp. 1653–1655.

Bhushan, B. (Editor), 1998,Tribology Issues and Opportunities in MEMS, Kluwer Academic Publisher.

Bhushan, B., 1999a, “Chemical, Mechanical and Tribological Characterization of Ultra-Thin and Hard Amorphous Carbon Coatings as Thin as 3.5nm: Recent Developments,”Diamond and Related Materials, Vol. 8, pp. 1985–2015.

Bhushan, B., 1999b,Handbook of Micro/Nanotribology, CRC press.

Bull, S. J., 1997, “Failure Mode Maps in the Thin Film Scratch Adhesion Test,”Tribology International, Vol. 30, pp. 491–498.

Chung, K. H. and Kim, D. E., 2003, “Fundamental Investigation of Micro Wear Rate Using an Atomic Force Microscope,”Tribology Letters, Vol. 15, pp. 135–143.

Erdemir, A., Fenske, G. R., Terry, J., and Wilbur, P., 1997, “Effect of Source Gas and Deposition Method on Friction and Wear Performance of Diamondlike Carbon Films,”Surface and coatings Technology, Vol. 94–95, pp. 525–530.

Huang, L.-Y., Xu, K.-W., and Li, J., 2002, “Evaluation of Scratch Resistance of Diamond- Like Carbon Films on Ti Alloy Substrate by Nano-Scratch Technique, “Diamond and Related Materials, Vol. 11, pp. 1505–1510.

Hwang, D. H., Kim, D. B., and Lee, S. J., 1999, ”Influence of Wear Particle Interaction in the Sliding Interface on Friction of Metals,”Wear, Vol. 225–229, pp. 427–439.

Khurshudov, A. and Kato, K., 1995, “Wear at the Atomic Force Microscope Tip Under Light Load, Studied by Atomic Force Microscopy,”Ultramicroscopy, Vol. 60, pp. 11–16.

Krache, B. and Damaschke, B., 2000, “Measurement of Nanohardness and Nanoelasticity of Thin Gold Films with Scanning Force Microscope,”Applied Physics Letters, Vol. 77, pp. 361–363.

Lemoine, P. and Laughlin, J. Mc, 1999, “Nano- mechanical Measurements on Polymer Using Contact Mode Atomic Force Microscopy,”Thin Solid Films, Vol. 339, pp. 258–264.

Liu, Y., Erdemir, A., and Meletis, E. I., 1996, “A Study of the Wear Mechanism of Diamond- Like Carbon Films,”Surface and Coatings Technology, Vol, 82, pp. 48–56.

Martinez, E., Andujar, J. L., Polo, M. C., Esteve, J., Robertson, J., and Milne, W. I., 2001, “Study of the Mechanical Properties of Tetrahedral Amorphous carbon Films by Nanindentation and Nanowear Measurements,”Diamond and Related Materials, Vol. 10, pp. 145–152.

Menon, A. K., 2000, “Interface tribology for 100 Gb/in2,”Tribology International, Vol. 33, pp. 299–308.

Oliver, W. C. and Pharr, G. M., 1992, “An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments,”Journal of Materials Research, Vol. 7, pp. 1564–1583.

Petzold, M., Landgraf, J., Futing, M., and Olaf, J. M., 1995, “Application of Atomic Force Microindentation Testing,”Thin Solid Films, Vol. 264, pp. 153–158.

Robertson, J., 1992, “Mechanical Properties and Structure of Diamond-Like Carbon,”Diamond and Related Materials, Vol. 1, pp. 397–406.

Staedler, T. and Schiffman, K., 2001, “Correlation of Nanomechanical and Nanotribological Behavior of Thin DLC Coatings on Different Substrates,”Surface Science, Vol. 482–485, pp. 1125–1129.

Sundararajan, S. and Bhushan, B., 1998, “Micro/Nanotribological Studies of Polysilicon and SiC Films for MEMS Applications,”Wear, Vol. 217, pp. 251–261.

Sung, I. H. and Kim, D. E., 2003, “Fabrication of Micro/Nano-Patterns Using MC-SPL (Mechano-Chemical Scanning Probe Lithography) Process,”International Journal of Korean Society of Precision Engineering, Vol. 4, pp. 22–26.

Valli, J., Maekela, U., Matthews, A., and Murawa, V., 1985, “TiN Coating Adhesion Studies Using the Scratch Test Method,”Journal of Vacuum Science and Technology A, Vol. 3, pp. 2411–2414.

Zhao, Q., Zhao, Z., Kazazic, E., Embree, M., Trinh, P., Lam, T., and Chang, S., 2002, “Investigation of Scratch Resistance of Thin Carbon Overcoat Media Using Micro Scratch Testing,”Wear, Vol. 252, pp. 654–661.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chung, KH., Lee, JW. & Kim, DE. Nano-mechanical and tribological characteristics of ultra-thin amorphous carbon film investigated by afm. KSME International Journal 18, 1772–1781 (2004). https://doi.org/10.1007/BF02984326

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02984326