Abstract

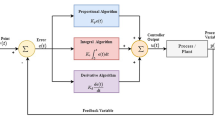

We describe a looper controller design for a hot strip finishing mill in steel plants. The main function of the looper system is to balance the mass flow of the strip by accumulating material in the middle of the stands. Another function is to control the strip tension which influences the width of the strip. To ensure strip quality, it is very important to control the tension of the hot strip finishing mill. However, because there is a mutual interaction between the looper angle and the strip tension, it is difficult to control the looper system. Previous researches examined only the operation of a single stand. But it is not sufficient to examine the operation and effect of whole stands because the operation is wholly interdependent. In this paper, we present a full model of the hot strip finishing mill in order to more effectively control strip tension. We propose several control methods for the full-stand hot strip finishing mill, denoted as conventional PI, PI with cross gain, and coefficient diagram method (CDM) PID control. In the real plants, there are some problems by using higher order controllers such as LQ, LQG and H∞. By comparison, the PID controller is very simple and easy to apply to all real plants. To that end, we present our findings on PID controls and their potential use in the hot strip finishing mill.

Similar content being viewed by others

References

Hearns, G. and Grimble, M. J., 1997, “Multi-variable Control of a Hot Strip Finishing Mill,”Proceedings of the American Control Conference Albuquerque, New Mexico, pp. 3775–3779.

Hesketh, T., Jiang, Y. A., Climents, D. J., Butler, D. H. and van der Laan, R., 1998, “Controller Design for Hot Strip Finishing Mills,”IEEE Trans, on Control System Techology, Vol. 6, No. 2, pp. 208–219.

Man Hyung Lee, 2001,Development of a High-Precision Automatic Control System for Hot-Strip Mill Finisher, RIMT, Pusan National University (The last report of first year), in Korea.

Manabe, S., 1997,An Algebraic Approach to Control System Design; Coefficient Diagram Method, (Lecture note), Chungbuk National University, in Korea.

Manabe, S., 1998, “Coefficient Diagram Method,”Proc. of 14 th IF AC Symposium on Automatic Control in Aerospace, pp. 199–210.

Masanoti Shioya, Naohatu Yoshitani, and Takatsugu Ueyama, 1995, “Noninteracting Control with Disturbance Compensation and its Application to Tension-Looper Control for Hot Strip Mill,”IEEE, pp. 229–234.

Myungjun, H., 1998, “A CDM for High-Order Plant,”Proc. of the 13 th KACC, pp. 793–795, in Korea.

Shin, K. H. and Hong, W. K., 1998, “Real-Time Tension Control in a Multi-Stand Rolling System,”KSME International Journal, Vol. 12, No. 1, pp. 12–21, in Korea.

Young-Choi Kim, 2001, “Application of CDM to MIMO System: Control of Hot Rolling Mill,”Transactions on Control, Automation and Systems Engineering, Vol. 3, No. 4, pp. 250–256, in Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahn, B.J., Choi, J.Y., Chang, Y.S. et al. On the full stand modeling and tension control for the hot strip finishing mill with PID structure. KSME International Journal 18, 1062–1073 (2004). https://doi.org/10.1007/BF02983281

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02983281