Abstract

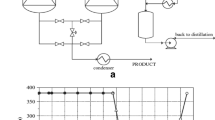

Modern ethanol distillation processes are designed to ensure removal of all ethanol from the column bottoms, i.e., to levels <100 ppm ethanol, and utilize substantial stripping steam to achieve this result. An alternate approach using sorption was attempted as a means to reduce energy requirements in the stripping section, and thereby reduce cost. Adsorbents tested for use in such an application showed that carbonaceous supports, in particular Ambersorb XEN 572, gave alcohol-free water as effluent when a 1% (w/w) starting ethanol concentration was passed downflow at 1 bed vol/h over a fixed-bed adsorber at 70°C. Regeneration was readily achieved at 70–90°C using hot air, vacuum, superheated steam, or hot water to strip the ethanol from the column, and yielded ethanol streams containing a maximum of 5.9% alcohol, with average concentrations of 2.5–3.5% depending on the regeneration method used. These experimentally determined operating conditions combined with distillation energy calculations have enabled development of a process concept for sorptive concentration of dilute ethanol which is more energy efficient than distillation alone. The combination of existing distillation and corn grit drying technologies, with sorptive recovery of dilute ethanol (from the column bottoms) shows promise of recovering a fuel grade, 99.4% ethanol product from a 4.5% ethanol broth with an energy requirement of 23,100 BTU/gal. The potential energy saving of 3600 BTU/gal over distillation alone corresponds to 1.8¢/gal, and provides motivation for further examination of this approach in reducing costs of ethanol production from biomass.

Similar content being viewed by others

Abbreviations

- Cp :

-

specific heat capacity of water

- D:

-

mass flow rate of overhead product

- mc :

-

mass flow rate of cooling water in overhead condenser

- ms :

-

mass flow rate of steam in reboiler

- RD :

-

R, reflux ratio for distillation column

- RDmin :

-

Rmin, minimum reflux ratio

- l:

-

latent heat of vaporization of liquid in bottoms

- ls :

-

latent heat of vaporization of steam

- ΔT:

-

rise in temperature of cooling water in overhead condenser

References

Ladisch, M. R. and Westgate, P. J. (1994),Improvements in Separation and Recovery Technology For Lower Biofuel Costs, Proceedings of Corn Utilization Conference V Corn Growers Association, St. Louis, MO.

Ladisch, M. R. and Schwandt, R. (1992), inTechnology for Expanding the Biofuels Industry. Proceedings of workshop sponsored by DOE, USDA and Renewable Fuels Association in Chicago, p. II–4.

David, M. L., Hamnzaker, G. S., Buzenberg, R. J., and Wagner, J. P. (1978), inGasohol Economic Feasibility Study, Development Planning and Research Assoc., Inc., Manhattan, KS.

Ghose, T. K. and Tyzgi, R. D. (1979),Biotechnol. Bioeng. 21, 1387.

Hohmann, N. and Rendleman, C. M. (1993), inEmerging Technologies in Ethanol Production, USDA Agriculture Information Bulletin No. 663, p. 1.

Ladisch, M. R. and Dyck, K. (1979).Science 205, 898.

Phillips, J. A. and Humphrey, A. E. (1983), inWood and Agricultural Residues: Research in Use for Feed, Fuels, and Chemicals, Soltes, E. J., ed., Academic, New York, p. 503.

Robertson, G. H., Doyle, L. R., and Pavlath, A. E. (1983),Biotechnol. Bioeng. 25, 3133.

Crawshaw, J. P. and Hills, J. H. (1990),Ind. Eng. Chem. Res.29, 307.

Voloch, M., Ladisch, M. R., Bienkowski, P., and Tsao, G. T. (1984),Cereal Polysaccharides in Technology and Nutrition, Rasper, V. F. ed., American Association of Cereal Chemists, St. Paul, MN, p. 103.

Hong, J., Voloch, M., Ladisch, M. R., and Tsao, G. T. (1982),Biotechnol. Bioeng. 24, 725.

Ladisch, M. R., Voloch, M., Hong, J., Bienkowski, P., and Tsao, G. T. (1984),Ind. Eng. Chem. Process Design Dev. 23, 437.

Hills, J. H. and Pirzada, I. M. (1989),Chem. Eng. Res. Des. 67, 442.

Hassaballah, A. A. and Hills, J. H. (1990),Biotechnol. Bioeng. 35, 598.

Bienkowski, P. R., Barthé, A., Voloch, M., Neuman, R. N., and Ladisch, M. R. (1986),Biotechnol. Bioeng. 28, 960.

Neuman, R., Voloch, M., Bienkowski, P., and Ladisch, M. R. (1986),Ind. Eng. Chem. Fundam. 25, 422.

Walsh, P. K., Liu, C. P., Findley, M. E., Liapis, A. I., and Siehr, D. J. (1983),Biotechnol. Bioeng. Symp. 13, 629.

Lee, J. Y., Westgate, P. J., and Ladisch, M. R. (1991),AIChE J. 37, 1187.

Westgate, P. J. and Ladisch, M. R. (1993),Ind. Eng. Chem. Res. 32, 1676.

Goetz, R. J. (1995), In Forefront, Goetz, R., ed. AGAD, Purdue University, West Lafayette, IN.

Katzen, R., Diebold, V. B., and Moon, G. B. (1969), US Patent 3, 445, 345.

Katzen, R. and Diebold, V. B. (1976), US Patent 3, 990, 952.

Lynd, L. R. and Grethlein, H. E. (1986)AIChE J. 32(8), 1347.

Carey, J. S. and Lewis, W. K. (1932),J. Ind. Eng. Chem. (24), 882.

Hong, J., Ladisch, M. R., and Tsao, G. T. (1981),J. Chem. Eng. Data 26(3), 305–307.

Dalager, P. (1969),J. Chem. Eng. Data 14(3), 298–301.

Altsheler, W. B., Unger, E. D., and Kolachov, P. (1951),J. Ind. Eng. Chem. 43(11), 2559–2564.

McCabe, W. L., Smith, J. C., and Harriott, P. (1985), inUnit Operations of Chemical Engineering. McGraw-Hill, New York, p. 489.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gulati, M., Westgate, P.J., Brewer, M. et al. Sorptive recovery of dilute ethanol from distillation column bottoms stream. Appl Biochem Biotechnol 57, 103–119 (1996). https://doi.org/10.1007/BF02941692

Issue Date:

DOI: https://doi.org/10.1007/BF02941692