Abstract

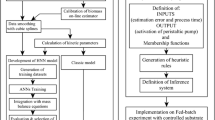

In order to control glucose concentration during fed-batch culture for antibiotic production, we applied so called “software sensor” which estimates unmeasured variable of interest from measured process variables using software. All data for analysis were collected from industrial scale cultures in a pharmaceutical company. First, we constructed an estimation model for glucose feed rate to keep glucose concentration at target value. In actual fed-batch culture, glucose concentration, was kept at relatively high and measured once a day, and the glucose feed rate until the next measurement time was determined by an expert worker based on the actual consumption rate. Fuzzy neural network (FNN) was applied to construct the estimation model. From the simulation results using this model, the average error for glucose concentration was 0.88 g/L. The FNN model was also applied for a special culture to keep glucose concentration at low level. Selecting the optimal input variables, it was possible to simulate the culture with a low glucose concentration from the data sets of relatively high glucose concentration. Next, a simulation model to estimate time course of glucose concentration during one day was constructed using the on-line measurable process variables, since glucose concentration was only measured off-line once a day. Here, the recursive fuzzy neural network (RFNN) was applied for the simulation model. As the result of the simulation, average error of RFNN model was 0.91 g/L and this model was found to be useful to supervise the fed-batch culture.

Similar content being viewed by others

References

Aiba, S., A. E. Humphrey, and N. F. Millis (1973)Biochemical Engineering. pp. 85–86. University of Tokyo Press, Tokyo, Japan.

Reed, G. (1981)Prescott and Dunn's Industrial Microbiology. p. 36. AVI Publishing Co., Westport, Conn., USA.

Lin, H. K., S. Iijima, K. Shimizu, F. Hishinuma, and T. Kobayashi (1989) Control of gene expression from theSUC2 promoter ofSaccharomyces cerevisiae with the aid of a glucose analyser.Appl. Microbiol. Biotechnol. 32: 313–316.

Linko, S., Y. Zhu, and P. Linko (1999) Applying neural networks as software sensors for enzyme engineering.TIBTECH 17: 155–162.

Thibult, J., V. V. Breusegem, and A. Cheruy (1990) On-line prediction of fermentation variables using neural networks.Biotechnol. Bioeng. 36: 1041–1048.

Hanai, T., A. Katayama, H. Honda, and T. Kobayashi (1997) Automatic fuzzy modeling forGinjo sake brewing process using fuzzy neural networks.J. Chem. Eng. Jpn. 30: 94–100.

Honda, H., T. Hanai, A. Katayama, H. Tohyama, and T. Kobayashi (1998) Temperature control ofGinjo sake mashing process by automatic fuzzy modeling using fuzzy neural networks.J. Ferment. Bioeng. 85: 107–112.

Tomida, S., T. Hanai, N. Ueda, H. Honda, and T. Kobaya-shi (1999) Construction of COD simulation model for activated sludge process by fuzzy neural network.J. Biosci. Bioeng. 88: 215–220.

Tomida, S., T. Hanai, H. Honda, and T. Kobayashi (2000) Construction of COD simulation model for activated sludge process by recursive fuzzy neural network.J. Chem. Eng. Jpn. 34: 369–375.

Horikawa, S., T. Furuhashi, and Y. Uchikawa (1991) A study on fuzzy modeling using fuzzy neural networks.Proc of International Fuzzy Engineering Symp.'91. November 13–15. Yokohama, Japan.

Rumelhart, D. E., G. E. Hinton, and R. J. Williams (1986) Learning internal representations by error propagation.Parallel Distributed Processing 1: 318–362.

Hanai, T., A. Kakamu, H. Honda, T. Furuhashi, Y. Uchikawa, and T. Kobayashi (1996) Modeling of total evaluation process ofGinjo sake using a fuzzy neural network.Trans. Soc. Instrument Control Engineers 32: 1113–1120.

Adachi, S. (1996)Identification of System Variables for Control. (in Japanese), pp. 115–131. Tokyo Denki Daigaku Shuppan Kyoku, Tokyo, Japan.

Kreyszig, E. (1988)Advanced Engineering Mathematics. (In Japanese) pp. 29–33. Baifuukan, Tokyo, Japan.

Gen, M. and K. Ida (1988)Library for Numerical Calculation Based on Turbo C. (in Japanese), pp. 129–134. HBJ Shuppan Kyoku, Tokyo, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Imanishi, T., Hanai, T., Aoyagi, I. et al. Software sensing for glucose concentration in industrial antibiotic fedbatch culture using fuzzy neural network. Biotechnol. Bioprocess Eng. 7, 275–280 (2002). https://doi.org/10.1007/BF02932836

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02932836