ABstract

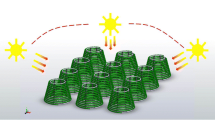

A photobioreactor was constructed in the form of a Perspex column 900 mm tall with an internal diameter of 70 mm. The reactor volume was 1.8 L and the light source consisted of a metal-halide lamp to reproduce sunlight. Light was distributed through the culture using a new type of optical fiber that diffuses light out through its surface, perpendicular to the fiber axis. A cluster of 661 light-diffusing optical fibers (LDOFs) pass from the light source through the reactor column (60-cm culture depth) and are connected to a mirror at the top of the reactor. This biosolar reactor has been used for the production of glutamate from CO2 by the marine cyanobacterium Synechococcus sp. NKBG040607. We present here details of the construction of the biosolar reactor and characterization of its properties. The effect of light intensity on glutamate production was measured. Carbon dioxide-to-glutamate conversion ratios were determined at different cell densities: the maximum conversion ratio (28%) was achieved at a cell density of 3x108 cells/mL. A comparison of glutamate production using the LDOF biosolar reactor described here with production by batch culture using free or immobilized cells showed that use of an optical-fiber biosolar reactor increased glutamate-production efficiency 6.75-fold. We conclude that as a result of its high surface-to-volume ratio (692/m) increased photoproduction of useful compounds may be achieved. Such a system is generally applicable to all aspects of photobiotechnology.

Similar content being viewed by others

References

Pimentel, D. and Pimentel, M. (1979),Food, Energy and Society, Edward Arnold, London.

Pirt, S. J. (1982),J. Chem. Technol. Biotechnol. 32, 198–202.

Pirt, S. J., Lee, Y. K., Walach, M. R., Pirt, M. W., Balyuzi, H. H. M., and Bazin, M. J. (1983),J. Chem. Technol. Biotechnol. 33, 35–58.

Myers, J. and Graham, J. R. (1961),Plant Physiol. 36, 342–346.

Ramos de Ortega, A. and Roux, J. C. (1986),Biomass 10, 141–156.

Matsunaga, T., Nakamura, N., Tsuzaki, N., and Takeda, H. (1988),Appl. Microbiol. Biotechnol. 28, 373–376.

Rippka, R., Deruelles, J., Waterbury, J. B., Herdman, M., and Stanier, R. Y. (1979),J. Gen. Microbiol. 111, 1–61.

Bernt, E. and Bergmeyer, H. U. (1973),Methods of Enzymatic Analysis, Bergmeyer, V., ed., Academic, New York, pp. 1704–1708.

Mori, K. (1986),Biotechnol. Bioeng. Symp. 15, 331–336.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Matsunaga, T., Takeyama, H., Sudo, H. et al. Glutamate production from CO2 by Marine CyanobacteriumSynechococcus sp.. Appl Biochem Biotechnol 28, 157–167 (1991). https://doi.org/10.1007/BF02922597

Issue Date:

DOI: https://doi.org/10.1007/BF02922597