Abstract

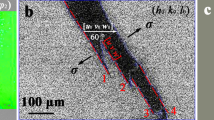

A special constant deflection device for TEM has been designed, and then change of dislocation configuration ahead of a crack tip during stress corrosion cracking (SCC) of brass in water and of Ti−24Al−11Nb alloy in methanol and initiation of SCC can be observed in TEM.In situ tensile test in TEM for brass was carried out for comparison. The results show that anodic dissolution during SCC can facilitate dislocation emission, multiplication and motion, and a dislocation free zone (DFZ) is formed. The stress at a particular site in the DFZ, which is an elastic zone and is thinned gradually through corrosion-enhanced dislocation emission and motion, is possibly up to the cohesive strength, resulting in initiating of a nanocrack of SCC in the DFZ or sometimes at the crack tip. Because of the action of the corrosion solution the nanocrack of SCC propagates into a cleavage or intergranular microcrack rather than blunts into a void likein situ tension in TEM.

Similar content being viewed by others

References

Chu, W. Y., Ya, J., Hsiao, C. M., Stress corrosion cracking of austenitic stainless steel under compressive stress,Corrosion, 1984, 40: 302.

Sieradzki, K., Newman, R. C. B., Brittle behaviour of ductile metals during stress-corrosion cracking,Phil. Mag. A, 1985, 51: 95.

Galvele, J. R., A stress corrosion cracking mechanism based on surface mobility,Corros. Sci., 1987, 27: 1.

Jones, D. A., A united mechanism of stress corrosion and corrosion fatigue cracking,Metall. Trans., 1985, 16A: 1133.

Magnin, T., Chieragatti, R., Oltra, R., Mechanism of brittle fracture in a ductile 310 alloy during stress corrosion,Acta Metall. Mater., 1990, 38: 1313.

Kaufman, M. J., Fink, J. I., Evidence for localized ductile fracture in the brittle transgranular SCC of ductile FCC alloys,Acta Metall., 1985, 36: 2213.

Flanagan, W. F., Bastias, P., Lichter, B. D., A theory of transgranular stress-corrosion cracking,Acta Metall. Mater., 1991, 39: 695.

Flanagan, W. F., Zhong, L., Lichter, B. D., A mechanism for transgranular stress-corrosion cracking,Metall. Trans., 1993, 24A: 553.

Rios, R., Magmin, T., Noel, D.et al., Critical analysis of alloy 600 SCC mechanism in primary water,Metall. Mater. Trans., 1995, 26A: 925.

Uhlig, H. H., Effect of surface dissolution on plastic deformation of iron and steel,J. Elec. Soc., 1976, 123: 1699.

Smialowski, M., Kostansking, J., Creep and stress corrosion cracking of austenitic stainless steel in boiling 35% magnesium chloride solution,Corros. Sci., 1979, 19: 1019.

Gu, B., Chu, W. Y., Jiao, I. J.et al., The facilitating effect of anodic polarization on ambient creep of brass,Corrosion Sci., 1994, 44: 1437.

Huang, Y., Cao, C., Lin, H.et al., SCC mechanism of AISI 321 in acidic chloride solution,Acta Metall. Sinica (in Chinese), 1993, 29: B212.

Wei, X. J., Zhou, X. Y., Ke, W., Investigating deformation at a crack tip during corrosion fatigue using laser moir interferometry technology,Acta Metall. Sinica (in Chinese), 1993, 29: B269.

Swann, P. R., Emburry, J. D., Initiation of stress corrosion cracking, inHigh Strength Materials (ed. Zackey, V. F.), New York: John Wiley, 1965, 327.

Huang, Y. H., Chen, Q. Z., Yuan, C. Y.et al., In situ TEM observations of dislocation emission and motion induced by anodic dissolution in 310 steel,Acta Metall. Sinica (in Chinese), 1994, 30: B452.

Chen, Q. Z., Chu, W. Y., Hsiao, C. M.,In situ TEM observations of nucleation and bluntness of nanocracks in thin crystals of 310 stainless steel,Acta Metall. Mater., 1995, 43: 4371.

Chu, W. Y., Zhang, Y., Wang, Y. B.et al., Thein situ TEM observation of nanocrack in titanium aluminide,Science in China, Ser. A, 1995, 38: 233.

Chu, W. Y., Gao, K. W., Wang, Y. B.et al., Nucleating and propagation of nanocrack in dislocation free zone in brittle material,Science in China, Ser. A, 1995, 38: 1501.

Parkins, R. N., Rangel, C. M., Yu, J., Stress corrosion cracking of α-brass in waters with and without additions,Metall. Trans., 1985, 16A: 1671.

Zhang, Y., Chu, W. Y., Wang, Y. B.et al., Interphase stress corrosion crack,Sci. Metall. Mater., 1995, 32: 657.

Ohr, S. M., An electron microscope study of crack tip deformation and its impact on dislocation theory of fracture,Mater. Sci. Eng., 1983, 59: 1.

Nelson, J. C., Oriani, R. A., Stress generation during anodic oxidation of titanium and aluminum,Corros. Sci., 1993, 34: 307.

Qiao, L. J., Chu, W. Y., Hsiao, C. M., Hydrogen-facilitated corrosion and SCC of stainless steel of type 310,Metall. Trans. A, 1993, 24: 959.

Author information

Authors and Affiliations

Additional information

Project supported by the National Natural Science Foundation of China.

Rights and permissions

About this article

Cite this article

Chu, W., Gu, B., Gao, K. et al. Corrosion-enhanced dislocation emission and motion resulting in initiation of stress corrosion cracking. Sci. China Ser. E-Technol. Sci. 40, 235–242 (1997). https://doi.org/10.1007/BF02916598

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02916598