Abstract

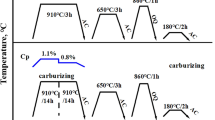

This article describes an experiment to determine the effect of retained austenite on the chipping of the case-hardened layer of Cr−Ni−W carburized steel by examining the same case-hardened layer with varying amounts of retained austenite after different heat treatments. The existence of a critical load level was established; contact fatigue resistance can be improved when the loads are above critical. This is determined by deformation of the austenite structure and substructure, the austenite-martensite transformation under the influence of the load, and the retention of the deformed austenite structure in the martensite.

Similar content being viewed by others

References

V.S. Sagaradze,The Increasing of Reliability of Carburized Parts (in Russian) (Moscow: Mashinostroyenie, 1985).

G.K. Trubin,Contact Fatigue of Gear Materials (Moscow: Mashinostroyenie, 1972).

N.M. Ryzhov and S.A. Pakhomova, “Effectivity of Carburized Steels Heat Shotpeening” (in Russian)Metallovedeniye I Termicheskaya Obrabotka Metallov, 5 (1994), pp. 21–24.

B.B. Vinokur, “The Composition of the Solid Solution Structure and Contact Fatigue of the Case-Hardened Layers,”Met. Trans., 24A, (5) (1993), pp. 1163–1169.

N.A. Filippov, V.S. Litvinov, and Yu.R. Nemirovsky,Steels With Metastable Austenite (Moscow: Metallurgiya, 1988).

E.B. Cula and S.V. Radcliffe, “Thermomechanical Treatment of Steel,”J. of Metals, 15 (10) (1963), pp. 17–27.

S. Putko and M. Seczerek, “What We Know About Spalling” (in Ukrainian),Fracture Mechanics: Success and Problems. Transactions of 8 th International Conference of Fracture (Lvov: Ukrainian Academy of Science, 1993), pp. 196–204.

A.L. Geller and B.B. Vinokur, “Phase Composition and Contact Fatigue Strength of Case-Hardened Steel,”Russian Metallurgy, 3 (1986), pp. 194–198.

L. Horg and C. Jumin, “The Investigation of Wear Resistance of Bearing Steel With Block Type Residual Austenite by Sloding,”Iron and Steel, 28 (4) (1993), pp. 44–51.

I. Atsushi, J. Hiroshi, and I. Tsuyoshi, “Effect of Retained Austenite on the Fatigue Properties of Carburized Steel,”KOBELKO Technology Review, 17 (1994) pp. 49–56.

J.R. McKinney and R.J. Swegger, “The Way of Steel Parts Carburizing,” U.S. patent no. 415387 (1983).

B.B. Vinokur, S.E. Kondratyuk, and O.G. Kasatkin, “Contact Strength of Carburized Layer of Steel 18CrMnNiMoV,”Russian Metallurgy, 2 (1988), pp. 169–173.

A.L. Geller and V.N. Yurko, “The Residual Austenite and Wear Resistance of Case-Hardened Alloyed Steels,”Izvestiya Vuzav Chernaya Metallurgiya, 6 (1991), pp. 66–70.

A.L. Geller, “Thin Structure of Residual Austenite of Cr−Mn and Cr−Ni Case-Hardened Steels,”Alloying, Structure, and Properties of Case-Hardened Steels (Kiev: Institute of Casting Problems of Ukrainian Academy of Science, 1992), pp. 31–44.

I.M. Lyubarsky,Increasing the Wear Resistance of Heavy-Duty Gears (Moscow: Mashinosnroyenie, 1965).

W. Georgy, “A Review of Some Aspects of Fatigue Crack Growth under Variable Amplitude Loading,”Int. J. of Fatigue, 14 (1992), pp. 337–342.

Additional information

Authors' Note: Alloyed steel compositions are presented in the Soviet standard. The first two numbers give the approximate carbon content in hundredths of a percent. The number after the element shows the approximate percentage of the alloying elements. The number one or no number at all means the percentage is about one or less.

Bertold B. Vinokur earned his Doctor of Technical Science in physics of metals and metal science at the Ukrainian Academy of Science, Ukraine, in 1978. He is currently retired. Dr. Vinokur is a member of TMS.

Alexandr L. Geller earned his Doctor of Technical Science in metal science and heat treatment at Donetsk Technical University, Ukraine, in 1997. He is currently an assistant professor in the Department of Materials Science and Engineering at Donetsk Technical University, Donetsk, Ukraine.

Rights and permissions

About this article

Cite this article

Vinokur, B.B., Geller, A.L. The effect of retained austenite on contact fatigue in Cr−Ni−W carburized steel. JOM 49, 69–71 (1997). https://doi.org/10.1007/BF02914356

Issue Date:

DOI: https://doi.org/10.1007/BF02914356