Abstract

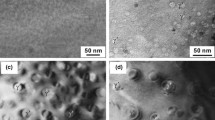

Creep induced instability of strengthening precipitates at grain boundaries is of general concern in the applications of many high temperature alloys. Having shown that the general validity of the existing mechanism for such an instability in nickel-base superalloys may be considered suspect, this paper reports and discusses the effects of both tensile and compressive creep on γ′ grain boundary precipitate morphology in an alloy consisting of γ′ (Ni3Al) precipitates in a γ (nickel solid solution) matrix. We find that the uniform distribution of γ′ precipitates is altered by the application of uniaxial creep stress, with the stress-induced precipitate morphology depending strongly on stress sense. Tensile creep results in the dissolution of γ′ precipitates at grain boundaries aligned more or less transverse to the stress axis, with an accompanying increase in volume fraction of γ′ precipitates at grain boundaries oriented parallel to, or almost parallel to the stress axis. In contrast, the reverse change in morphology occurs during compressive creep. The observed morphology changes and their dependence on stress sense are shown to be consistent with the flow of chromium atoms from grain boundaries that are under normal compression towards grain boundaries that are under normal tension. The results conclusively demonstrate that Herring-Nabarro type diffusion in multiphase, polycrystalline alloys can cause chemical changes in grain boundary regions which, in the extreme, result in phase changes at grain boundaries. The results and proposed mechanism are discussed in terms of the findings of other investigations.

Similar content being viewed by others

References

J. K. Tien and S. M. Copley:Met. Trans., 1971, vol. 2, p. 215.

J. K. Tien and S. M. Copley:Met. Trans., 1971, vol. 2, p. 543.

C. P. Sullivan and M. P. Donachie, Jr.:Metals Eng. Quart., 1967, vol. 7, p. 36.

D. McLean:J. Inst. Metals, 1956, vol. 85, p. 468.

R. F. Decker:Symposium on Steel Strengthening Mechanisms, p. 147, Climax Molybdenum Co, Greenwich, Conn., 1970.

R. F. Decker and J. W. Freeman:Trans. TMS-AIME, 1960, vol. 218, p. 277.

M. J. Fleetwood:J. Inst. Metals, 1961–62, vol. 90, p. 429.

C. W. Weaver:J. Inst. Metals, 1961–62, vol. 90, p. 404.

G. N. Maniar:J. Inst. Metals, 1963, vol. 91, p. 350.

O. H. Kriege and J. M. Baris:Trans. ASM, 1969, vol. 62, p. 195.

J. R. Mihalisin and D. L. Pasquine:Intern. Symp. on Structural Stability in Superalloys, Seven Springs, Pa., Sept., 1968.

E. L. Raymond:Trans. TMS-AIME, 1967, vol. 239, p. 1415.

C. H. Wells and C. P. Sullivan:ASTM Spec. Tech. Publ. 459, 1969, p. 59.

D. J. Wilson:NASA Rept. 04368-16T, 1969.

L. R. Woddyatt, C. T. Sims, and H. J. Beattie, Jr.:Trans. TMS-AIME, 1966, vol. 236, p. 519.

C. T. Sims:J. Metals, 1966, vol. 18, p. 1119.

A. Taylor and R. W. Floyd:J. Inst. Metals, 1952–53, vol. 81, p. 451.

F. R. N. Nabarro:Report of a Conference on the Strength of Solids, p. 75, Physical Society, London, 1948.

C. Herring:J. Appl. Phys., 1950, vol. 21, p. 437.

G. B. Fedorov, E. A. Smimov, and F. I. Zhomov:Met. i Metallog. Chistykh Metallov, 1963, vol. 4, p. 110, AERE Trans. 1031, by J. J. Cornish, Atomic Energy Research Establishment, Harwell, 1965.

P. L. Farnsworth and R. L. Coble:J. Am. Ceram. Soc., 1966, vol. 49, p. 264.

R. L. Coble:J. App. Phys., 1963, vol. 34, p. 1679.

R. L. Squires, R. T. Weiner, and M. Phillips:J. Nucl. Mater., 1963, vol. 8, p. 77.

J. E. Harris and R. B. Jones:J. Nucl. Mater., 1963, vol. 10, p. 360.

A. Karim, D. L. Holt, and W. A. Backofan:Trans. TMS-AIME, 1969, vol. 245, p. 1131.

C. Crussard, J. Plateau, and G. Henry:Joint Intern. Conf. on Creep, p. 1–91, Inst. Mech. Engrs., London, 1963.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tien, J.K., Gamble, R.P. The influence of applied stress and stress sense on grain boundary precipitate morphology in a nickel-base superalloy during creep. Metall Trans 2, 1663–1667 (1971). https://doi.org/10.1007/BF02913891

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02913891