Summary

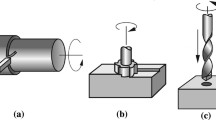

Blanking and machining are commonly used in processes to obtain the shape of many mechanical pieces. Although considerable number of experimental results exist, certain essential aspects of cutting are still not well understood. This comes from the complexity of the thermomechanical phenomena induced by the material separation as well as from the complexity of the dynamical behaviour of the whole workpiece/tool/machine system. Numerical simulations make it possible to go further in the comprehension and the prediction of machining and cutting processes.

In this work the state-of-the art is analysed and we present the most recent developments in the contribution of computational mechanics to numerical simulation of machining and blanking. This contribution is, on one hand, developed at a very global scale calledmacroscopic scale. At this scale a representation of the deformations of the piece is necessary, for example when thin walls are present, and when both predictions of the geometrical state of final surface and/or stability of the process are expected. On the other hand, the contribution is also located at a more local scale: themesoscopic scale. At this scale, the aim is the determination of thermomechanical sollicitations applied to the tool, the simulation of chip formation, or the description of residual states (mechanical, chemical) inside the workpiece after machining.

Similar content being viewed by others

References

http://www.maline.com/cutpro/.

AdvantedgeTM.

M. Touratier (1998). Computational models of chip formation in machining in a multi-scale approach. Present status and future needs. Technical Report, LM2S-Report, ENSAM Paris.

S. Jayarama, S. Kapoor and R.E. DeVor (2001). Estimation of the specific cutting pressures for mechanistic cutting force models.Int. J. Machine Tools, and Manufacture,41 (2), 265–281.

F. Atabey, I. Lazoglu and Y. Altintas. Mechanics of boring processes—Part I (2003)Int. J. Machine Tools and Manufacture,43 (5), 463–476.

H.E. Merritt (1965). Theory of self-excited machine tool chatter—resarch i.J. Engineering for Industry,17, 447–454.

F. Ismail and E. Soliman (1997). A new method for the identification of stability lobes in machining. Int. J. Machine Tools, and Manufacture,37 (6), 763–774.

F. Abrari, M.A. Elbestawi and A.D. Spence (1998). On the dynamics of ball end milling: modeling of cutting forces and stability analysis.Int. J. Machine Tools, and Manufacture,38, 215–237.

E. Budak and Y. Altintas (1998). Analytical prediction of chatter stability in milling-parti: General formulation.ASME Trans.—J. of Dynamic Systems. Measurement and Control,120, 22–30, March.

E. Budak and Y. Altintas (1998). Analytical prediction of chatter stability in milling-partii: Application of the general formulation to common milling systems.ASME Trans.-J. of Dynamic Systems, Measurement and Control,120, 31–36, March.

M.P. Volger, R.E. DeVor and S.G. Kapoor (2001). Nonlinear influence of effective lead angle in turning process stability.J. of Manufacturing Science and Engineering,124, 473–475.

Y. Altintas, S. Engin and E. Budak (1999) Analytical stability prediction and design of variable pitch cutters.J. of Manufacturing Science and Engineering,121, 173–178, May.

F. Lapujoulade (2003),Simulation des phénomènes vibratoires intervenant en usinage. PhD thesis, INSA Lyon et Université Claude Bernard Lyon I.

S. Eugin and Y. Altintas (2001). Mechanics and dynamics of general milling cutters. Part I: helical end mills.Int. J. Machine Tools, and Manufacture,41, 2195–2212.

S. Engin and Y. Altintas (2001). Mechanics and dynamics of general milling cutters. Part II: inserted cutters.Int. J. Machine Tools, and Manufacture,41, 2213–2231.

A. Grefio (2000). Calcul par ééments finis d'un banc d'essai. InPremières Assises Machines et Usinage à Grande Vitesse, March.

Y. Altintas (2000). Modelling approaches and software for predicting the performance of milling operations at mal-ubc. InCIRP 2000 Machining Workshop.

J. Gradišek, M. Kalveram, T. Insperger, K. Weinert, G. Stépán, E. Govekar and I. Grabec (2004). On stability prediction for low radial immersion milling. In A. Moisau and G. Poulachon (Eds.), 7th CIRP International Workshop on Modeling of Machining Operations, pp. 227–233.

D. Montgomery and Y. Altintas (1991). Mechanism of cutting force and surface generation in dynamic milling.J of Engineering for Industry,113, 160–168, May.

G. Coffignal, E. Beauchesne, K. Dekelba and N. Hakem (1996). Mechanical simulation of machining using cutting tools. In1st International Conference-IDMME'96, Volume 1, pp. 145–154.

A. Marty, P. Lorong and G. Coffignal (2000). Numerical simulation of a turning operation. InII International Seminar on Improving Machine Tool Performance, La Baule de Nantes de France, July.

S. Assouline, E. Beauchesne, G. Coffignal, P. Lorong and A. Marty (2002). Simulation numérique de l'usinage à l'échelle macroscopique: modèles dynamiques de la pièce.Mécanique et Industrie,3, 389–402.

F. Lapujoulade, T. Mabrouki, and K. Raissi (2002). Prédiction du comportement vibratoire du fraisage latéral de finition des piéces à parois minces.Mécanique et Industries,3, 403–418.

T. Van Hook (1986). Real-time shaded nc milling display. InSIGGRAPH'86, pp. 15–35.

G.M. Kim, P.J. Cho and C.N. Chu (2000). Cutting force prediction for scultured surface ball-end milling using z-map.Int. J. Machine Tools, and Manufacture,40, 277–291.

Y. Mizugaki, M. Hao and K. Kikkawa (2001). Geometric generating mechanism of machined surface by ball-nosed end milling. InAnnals of the CIRP, Volume 50.

S. Ratchev, S. Liu, W. Huang and A.A. Becker (2004). Milling error prediction and compensation in machining of low-rigidity parts.Int. J. Machine Tools, and Manufacture,44, 1629–1641.

K. Weinert and A. Zabel (2004). Simulation based tool wear prediction in milling of sculptured surfaces.Annals of the CIRP,53, 217–223.

W.M.M. Ng and S.T. Tan (2000). Incremental tessellation of trimmed parametric surfaces.Computer Aided Design,32(4), 279–294.

R. Radulescu, S.G. Kapoor and R.E. DeVor (1993). An investigation of variable spindle speed face milling for tool-work structures with complex dynamics: Part 1-simulation results. J. of Manufacturing Science and Engineering,64, 603–614.

R. Radulescu, S.G. Kapoor and R.E. DeVor (1993). An investigation of variable spindle speed face milling for tool-work structures with complex dynamics: Part 2-physical explanation.J. of Manufacturing Science and Engineering,64, 615–627.

Khaled Dekelbab (1995).Modélisation et simulation du comportement dynamique de l'ensemble Pièce-Outil-Machine en usinage par outil coupant. PhD thesis, Ecole Nationale Supérieure d'Arts et Métiers-CER de Paris.

K. Mehdi, J.-F. Rigal and D. Play (2002). Dynamic behavior of a thin-walled cylindrical workpiece during the turning process, Part 2: experimental approach and validation.J. of Manufacturing Science and Engineering,124, 569–580.

B.K. Choi and R.B. Jerard (1998).Sculptured surface machining. Kluwer Academic Publishers.

K.J. Bathe (1996).Finite Element Procedures. Prentice-Hall.

M. Géradin and D. Rixen (1996).Théorie des vibrations. Application à la dynamique des structures. Masson.

S.P.F.C. Jaspers and J.H. Dautzenberg (2002). Material behaviour in metal cuttingl: strains, stain rates and temperatures in chip formation.J. Material Processing Technology,121, 123–135.

J.-D. Kim and C.-H. Moon (1996) A study on microcutting for the configuration of tools using molecular dynamics.J. Material Processing Technology,59, 309–314.

R.G. Rentsch (2004). Molecular dynamics simulation of microscopic phenomena in cutting and forming processes. InESAFORM, pp. 93–96, Trondheim, Norway, April 28–30.

H. Hernst (1938). Physics of metal cutting.Machining of Metals—American Society for Metals, page 24.

H. Hernst and M.E. Merchant (1941). Chip formation, friction and high quality machined surfaces.Trans. American Society for Metals,29, 299–378.

M.E. Merchant (1945). Mechanics of the metal cutting process: I. Orthogonale cutting and type 2 chip.Journal of Applied Physics,16, 267–275.

N. Fang, I.S. Jawahir and P.L.B. Oxley (2001). A universal slip-line model with non-unique solutions for machining with curled chip formation and a restricted contact tool.Int. J. Mech. Sci.,43, 557–580.

A. Molinari and A. Moufki (2005). A new thermomechanical model of cutting applied to turning operations. part i. theory.Int. J. Machine Tools. and Manufacture,45, 166–180.

A. Moufki and A. Molinari (2005). A new thermomechanical model of cutting applied to turning operations. part ii. parametric study.Int. J. Machine Tools, and Manufacture,45, 181–193.

A. Moufki, A. Devillez, D. Dudzinski and A. Molinari (2004). Thermomechanical modelling of oblique cutting and experimental validation.Int. J. Machine Tools, and Manufacture,44, 971–989.

Y.K. Chou and H. Song (2005). Thermal modeling for white layer predictions in finish hard turning.Int. J. Machine Tools, and Manufacture,45, 481–495.

S.-L. Ko and A. Dornfeld (1996). Burr formation and fracture in oblique cutting.J. of Material Processing Technology,62, 24–36.

V.R. Marinov (2001). Hybrid analytical-numerical solution for the shear angle in orthogonal metal cutting—part i: theoretical foundation.Int. J. Mech. Sci.,43, 399–414.

K. Okushima and Y. Kakino (1971). The residual stress produced by metal cutting.Annals of the CIRP,20(1), 13.

A.O. Tay, M.G. Stevenson and G.D. Davis (1974). Using finite element method to determine the temperature distribution in orthogonal in orthogonal machining.Proceedings of Institute of Mechanical Engineers,188, 627.

M.G. Stevenson, P.K. Wright and J.G. Chow (1983). Further developments in applying finite element technique to the calculation of temperature distribution in machining and compressions with experiment.ASME Journal of Engineering for Industry,105, 149–154.

R. Natarajan and S. Jeelani (1983). Residual stresses in machining using finite element method.Computer in Engineering, Computer Software Applications,3, 79–80.

K.F. Ehmann, S.G. Kapoor, R.E. DeVor and I. Lazoglu (1997). Machining process modeling: A review.J. of Manufacturing Science and Engineering,119, 655–663.

J. Mackerle (1999). Finite-element analysis and simulation of machining: a bibliography (1976–1996).J. of Material Processing Technology,86, 17–44.

G.R. Johnson and W.H. Cook (1983). A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. InProceedings of the 7 th International Symposium on Ballistics, pp. 541–547, The Hague, Holland, April.

T. Ozel and E. Zeren (2004). Determination of material work flow stress and friction for fef of machining using orthogona cutting tests.J. Proc. Tec.,153–154, 1019–1025.

D. Steinberg, S. Cochram and M. Guinan (1980). A constitutive model for metals applicable at high-strain rate.J. of Applied Physics,51 (3), 1498–1504.

W.K. Rule and S. Jones (1998). A revised form for the johnson-cook strength model.Int. J. of Impact Engng,21(8), 609–624.

G.R. Johnson and W.H. Cook (1985). Fracture caracteristics of three metals subjected to various strains, strain rates, temperatures and pressure.Engineering Fracture Mechanics,21, (1), 31–48.

Z.-C. Lin and S.Y. Lin (1992). A coupled finite element model thermo-clastic-plastic large deformation for orthogonal cutting.J. of Engineering Mater. and Technol. 114, 218–226.

T. Shirakashi, K. Maekawa and E. Usui (1993). Flow stress of low carbon steel and high temperature and strain rate.J. of Jap. Society for Production Engng,17, 167–172.

Z.-C. Lin and Y.-Y. Lin (1999). Fundamental modeling for oblique cutting by thermo-elastic-plastic fem.Int. J. Mech. Sci.,41, 941–965.

A.G. Mamalis, M. Horváth, A.S. Branis and D.E. Manolakos (2001). Finite element simulation of chip formation in othogonal metal cutting.J. of Material Processing Technology, 110, 12–27.

Y.-C. Yen, A. Jain and T. Altan (2004). A finite element analysis of orthogonal machining using different tool edge geometries.J. of Material Processing Technology,146, 72–81.

J.S. Wu, O.W. Dillon and W.Y. Lu (1996). Thermo-viscoplastic modeling of machining process using a mixed finite element method.J. of Manufacturing Science and Engineering,118, 470–482.

D.-C. Ko, S.-L. Ko and B.-M. Kim (2002). Rigid-thermoviscoplastic finite element simulation of non-steady-state orthogonal cutting.J. of Material Processing Technology,130–131, 345–350.

J. Lemonds and A. Needleman (1986). Finite element analysis of shear localization in rate and temperature dependent solids.Mechanics of Materials,5, 339–361.

T.D. Marusich and M. Ortiz (1995). Modelling and simulation of high-speed machining.Int. J. Numer. Meth. in Engng,38, 3675–3694.

S. Lei, Y.C. Shin and F.P. Incorpera (1997). Material constitutive modeling under high strain rates and temperatures through orthogonal machining tests. InProceedings of Manufacturing Science and Engineering. ASME IMECE, MED, Volume6-2, pp. 91–98.

S. Lei, Y.C. Shin and F.P. Incorpera (1999). Thermo-mechanical modelling of orthogonal machining process by finite element analysis.Int J. Machine Tools, and Manufacture,39, (15), 731–750, May.

J. Söder and T. Altan (2001). Material database for manufacturing simulation (madams): Summary of the activities and flow stress database. ERC for Net Shape Manufactureing HPM/ERC/NSM-01-R-76, Ohio State University.

Firas Ali (2001),Modélisation et simulation thermomécaniques de la coupe des métaux. PhD thesis, Ecole Nationale Supérieure d'Arts et Métiers-CER de Paris, Juillet.

J.S. Strenkowski and J.T. Carroll (1986). An orthogonal metal cutting model based on an eulerian finite element method. InManufacturing Processes, Machines and Systems, Proceedings of the 13th NSF Conference on Production Research an Technology.

D.J. Benson and S. Okazawa (2004). Simulations of high-speed machining using a multimaterial finite element formulation. In S. Ghosh, J.C. Castro, and J.K. Lee (Eds.),NUMI-FORM, Material Processing and Design: Modeling, Simulation and Applications, pp. 1341–1346.

J.T. Carroll and J.S. Strenkowski (1988). Finite element models of orthogonal cutting with application to single point diamond turning.Int. J. Mech. Sci.,30, 899–920.

R.A. Riddle (1987). The effect of the failure criterion in the mumerical modeling of orthogonal metal cutting. Technical Report UCRL-93745, Lawrence Livermore Report.

H.T.Y. Yang, M. Heinstein and A.J.M. Shih (1989). Adaptative 2d finite element simulation of metal forming processes.Int. J. Numer. Meth. in Engng,28, 1409–1428.

K. Komvopoules and S.A. Erpenbeck (1991). Finite element modeling of orthogonal metal cutting.ASME Journal of Engineering for Industry,113, 253–267.

S.F. Wayne, C. Simmerman and D.A. Oniel (1993). Aspects of advanced cutting tool and chip-flow modeling. In H. Bildstein and R. Eck, editors,Procedings of the 13 th International Plansee Seminar, Volume 2, page 64 Metalwerk Plansee, Rentte.

A.J. Shih (1996). Finite element analysis of orthogonal metal cutting mechanics.Int. J. Machine Tools, and Manufacture,36 (2), 255–273.

M. Baker, J. Rosler, and C. Siemers (2002). A finite element model of high speed metal cutting with adiabatic shearing.Comp. and Struc.,80, 495–513.

H. Sasahara, T. Obikawa and T. Shirakashi (2004). Prediction model of surface residual stress within a machined surface by combining two orthogonal plane models.Int. J. Machine Tools. and Manufacture,44, 815–822.

L.-J. Xie, J. Schmidt, C. Schmidt and F. Biesinger (2005). 2d fem estimate of tool wear in turning operation.Wear,258, 1479–1490.

G. Camacho, T. Marusich and M. Ortiz (1996). Adaptative meshing methods for the analysis of unconstrained plastic flow.Advanced Computational Methods for Material Modeling,268, 71–83.

E. Ceretti, M. Lucchi and T. Altan (1999). FEM simulation of orthogonal cutting: serrated chip formation.J. of Material Processing Technology,95:17–26.

Y. B. Guo and D. W. Yen (2004). A fem study on mechanisms of discontinuous chip formation in hard machining.J. of Material Processing Technology,155–156, 1350–1356.

O. Pantalé, J.-L. Bacaria, O. Dalverny, R. Rakotomalala and S. Caperaa (2004). 2d and 3d numerical models of metal cutting with damage effects.Comp. Meth. Applied Mech. and Eng.,193, 4383–4399.

M. Barge, H. Hamdi, J. Rech and J-M. Bergheau (2005). Numerical modelling of orthogonal cutting: influence of numerical parameters.J. of Material Processing Technology. in press.

Deform 3d user manual, 1997.

E. Ceretti, C. Lazzaroni, L. Menegardo and T. Altan (2000). Turning simulations using a three-dimensional FEM code.J. of Material Processing Technology,98, 99–103.

R. Rokotomalala, P. Joyot and M. Touratier (1993). Arbitrary lagrangian-eulerian thermome-chanical finite element model of material cutting.Communication in Numerical Methods in Engineering,9, 975–987.

L. Olovsson, L. Nilsson and K. Simonsson (1999). An ALE formulation for the solution of two-dimensional metal cutting problems.Comp. and Struc.,72, 497–507.

M. Baker (2004). Finite element investigation of the flow stress dependence of chip formation.J. of Material Processing Technology.

M. Baker, J. Rosler and C. Siemers (2003). The influence of thermal conductivity on segmented chip formation.Computational materials Science,26, 175–182.

ABAQUS.Abaqus/Explicit User's Manual, HKS Inc., 1997.

ABAQUS.ABAQUS/Standard User's Manual. HKS Inc., 1997.

LS Dyna.Ls-dyna theorical Manual. L.S.T. Corporation California, USA, 1997.

Halil Gil, S. Engin Engin Kilic, and A. Ermai Tekkaya (2004). A comparison of orthogona cutting data from experiments with three ditherent finite element models.Int. J. Machini Tools, and Manufacture,44, 933–944.

E. Fratini, A. Lombardo and F. Micari (1996). Material characterization for the prediction of ductile fracture occurrence: an inverse approach.Journal of Materials Processing Technology, 60, 311–316.

E.H. Lee (1969). Elastic-plastic deformation at finite strains.J. Applied Mech. ASME,36. 1–6.

K.J. Bathe (1986).Finite Element procedures. Prentice Hall.

D. Perié, M. Vaz and D.R.J. Owen (1999). On adaptive strategies for large deformations of elasto-plastic solids at finite strains: computational issues and industrial applications.Comp Meth. Applied Mech. and Eng.,176, 279–312.

A.L. Eterovic and K.-J. Bathe (1990). A hyperelastic-based large strain elasto-plasstic constitutive formulation with combined isotropic-kiematic hardening using the logarithmic stress and strain measures.Int. J. Numer. Meth. in Engng,30, 1099–1114.

J.C. Simo (1992). Algorithms for static and dynamic multiplicative plasticity that preserve the classical return-mapping algorithm schemes of the infinitesimal theory.Comp. Meth. Applied Mech. and Eng.,99, 61–112.

A. Cuiti no and M. Ortiz (1992). A material-independent method for extending stress-update algorithms from small-strain plasticity to finite plasticity with multiplicative kinematics.Engimeering computations,9, 437–451.

J.C. Simo and C. Miehe (1992). Associative coupled thermoplasticity at finite strains: formulation numerical analysis and implementation.Comp. Meth. Applied Mech. and Eng.,98, 41–104.

J.C. Simo and T.J.R. Hughes (1998).Computational inelasticity. Springer-Verlag.

J.S. Chen, Y. Yoon and C.T. Wu (2002). Non-linear version of stabilized conforming nodal integration for galerkin mesh-free methods.Int. J. Numer. Meth. Engng,53, 2587–2615.

G. Taylor and H. Quinney (1934). The latent energy remaining in a metal after cold working.Proceedings of the Royal Society,143, 307–326.

B. Nayroles, G. Touzot and P. Villon (1992). Generalizing the finite elemnt method: diffuse approximation and diffuse elements.Computational mechanics,10, 307–318.

T. Belytschko, Y.Y. Lu and L. Gu (1994). Element-free galerkin methods.Int. J. Numer. Meth. in Engng,37, 229–256.

W.K. Liu, S. Jun and Y.F. Zhang (1995). Reproducing kernel particle methods.Int. J. Numer. Methods Fluids.,21, 1081–1106.

L.B. Lucy (1977). A numerical approach to the testing of fuion process.The astronomical journal,88, 1013–1024.

S. Gupta M. Sharan and E.J. Kansa (1997). Application of the multiquadratic method for numerical solution of elliptic partial differential equations.Applied Mathematics and Computation,84, 837–857.

N. Sukumar, B. Moran and T. Belytschko (1998). The natural elements method in solid mechanics.Int. J. Numer. Meth. in Engng,43, 839–887.

S. Li, W. Hoa and W.K. Liu (2000). Mesh-free simulations of shear banding in large deformation.Int. Journ. Solids. and Sruct.,37, 7183–7206.

I. Alfaro, D. Gonzalez, D. Bel, E. Cueto, M. Doblare and F. Chinesta (2004). Recent advances in the meshless simulation of aluminium extrusion and other related forming processes.Archives of Computational Methods in Engineering. to appear.

J. Yvonnet, P. Lorong, D. Ryckelvuck and F. Chinesta (2005). Simulating dynamic thermoelastoplasticity in large transformations witha adaptive refinement in the natural element method: application to shear banding.Int. J. Forming Processes. accepted.

J.S. Chen, C. Pan and C.T. Wu (1997). Large deformation analysis of rubber based on a reproducing kernel particle method.Computer methods in applied mechanics and enginnering,173, 99–109.

J. Dolbow and T. Belytschko (1999). Volumetric locking in the element-free galerkin method.Int. J. Numer. Meth. in Engng,46, 925–942.

W.K. Liu, S. Li and T. Belytschko (1997). Moving least square reproducing kernel method (i) methodology and convergence reproducing kernel particle methods.Comput. Meth. Appl. Mech. Engng.,143, 113–154.

P. Krysl and T. Belytschko (1996). Element-free galerkin: convergence of the continuous and discontinuous shape functions.Comp. Meth. Applied Mech. and Eng..

J. Yvonnet, D. Ryckelynck, P. Lorong and F. Chinesta (2004). A new extension of the natural element method for non convex and discontinuous domains: the constrained natural element method (c-nem).Int. J. Numer. Meth. in Engng,60, 1451–1474.

M. Sambridge, J. Braun and H. McQueen (1995). Geophysical parameterization and interpolation of irregular data using natural neighbours.Geophys. J. Int.,122, 837–857.

R. Sibson (1980). A vector identity for the dirichlet tesselations.Math. Proc. Camb. Phil. Soc.,87, 151–155.

H. Hiyoshi and K. Sugihara (2002). Improving continuity of voronoi-based interpolation over delaunay spheres.Computational Geometry,22, 167–183.

V.V. Belikov, V.D., Ivanov, V.K. Kontorovich, S.A. Korytnik and A.Y. Semenov (1997). The non-sibsonian interpolation: a new method of interpolation of the values of a function on an arbitrary set of points.Computational Mathematics and Mathematical Physics,37 (1), 9–15.

E. Cueto, M. Doblaré and L. Gracia (2000). Imposing essential boundary conditions in the natural elements method by means of density-scaled alpha-shapes.Int. J. Numer. Meth. in Engng,49, 519–546.

R. Seidel (1988). Constrained delaunay triangulations and voronoi diagrams with obstacles. In1978–1988 Ten Years IIG, pp. 178–191.

E. Schönhardt (1928). Uber die zerlegung von dreieckspolyedern in tetraeder.Math. Annalen,98.

JR Shewchuck (1998). Tetrahedral mesh generation by delaunay refinement. InProceedings of the fourteenth annual symposium on computational geometry, Minneapolis, Minnesota, pp. 86–95, June. Association for Computing Machinery.

JR Shewchuck (2000). Sweep algorithms for constructing higher-dimensional constrained delaunay triangulations. InProceedings of the sixteenth annual symposium on computational geometry, pp. 350–359, June. Association for Computing Machinery.

J. Yvonnet, F. Chinesta, P. Lorong and D. Rynckelynck (2005). The constrained natural element method (c-nem) for treating thermal models involving moving interfaces.International Journal of Thermal Sciences,44, 559–569.

J. Lemaitre and J.L. Chaboche (1990).Mechanics of solid materials. Cambridge University Press, UK.

J.-F. Yau, S.-S. Wang and H.T. Corten (1980). A mixed-moed crack analysis of isotropic solids using conservation laws of elasticity.J. Applied Mech. ASME,47, 335–341.

J.M. Melenk and I. Babuška (1996). The partition of unity finite element method: basic theory and applications.Comp. Meth. Applied Mech. and Eng.,139, 289–314.

O.C. Zienkiewicz and J.Z. Zhu (1987). A simple error estimator and adaptive procedure for practical engineering analysis.Int. J. Numer. Meth. in Engng. 24, 337–357.

N.-S. Lee and K.J. Bathe (1994). Error indicators and adaptive remeshing in large deformation finite element analysis.Finite Element Analysis Design,16, 99–139.

G.T. Camacho and M. Ortiz (1996). Computational modeling of impact damage in brittle materials.Int. J. Solids Struc.,33, 2899–2938.

P. Ladevèze (1998).Non Linear Computational Structural Mechanics, Springer.

I. Babuška and W.C. Rheinboldt (1979). Adaptive approaches and reliability estimations in finite elemenet analysis.Comp. Meth. Applied Mech. and Eng.,17/18, 519–40.

P. Ladevèzeand G. Coffignal and J.P. Pelle (1998). Accuracy of elastoplastic and dynamic analysis. InBabuška et al. eds., Accuracy estimates and adaptive refinements in finite element computations, pp. 86–95, John Wiley, June. Association for Computing Machinery.

T. Belytschko, B.L. Wong and E.J. Plakacz (1989). Fission-fusion adaptivity in finite elements for nonlinear dynamics of shells.Comp. and Struc.,33, 1307–1323.

M. Ortiz and J.J. Quigley (1991). Adaptive mesh refinement in strain localization problems.Comp. Meth. Applied Mech. and Eng.,90, 781–804.

L. Gallimard, P. Ladevèze and J.P. Pelle (1996). Error estimation and adaptivity in elastoplasticityInt. J. Numer. Meth. in Engng.,39, 189–217.

W.K. Lin, R.A. Uras and Y. Chen (1997). Enrichment of the finite element method with the reproducing kernel particle method.J. Applied Mech. ASME,64, 861–870.

Y. You, J.S. Chen and H. Lu (2003). Filters, reproducing kernel, and adaptive meshfree method.Computational mechanics,31, 316–326.

H-J. Chung and T. Belytschko (1998). An error estimate in the efg method.Computational Mechanics,21, 91–100.

C.K. Lee and C.E. Zhou (2003). On error estimation and adaptive refinement for element free Galerkin method. Part I: stress recovery and a posteriori error estimation.Comp. & Struc.,82(4–5), 413–428.

C.K. Lee and C.E. Zhou (2003). On error estimation and adaptive refinement for element free Galerkin method. Part II: adaptive refinement.Comp. & Struc.,82(4–5), 429–443.

H. Lu and J.S. Chen (2002). Adaptive meshfree particle method.Lecture notes in Computational Science and Engineering,26, 251–267.

J. Yoo, B. Moran and J.-S. Chen (1998). Stabilized conforming nodal integration in the natural-element method.Int. J. Numer. Meth. in Engng,60, 861–890.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lorong, P., Yvonnet, J., Coffignal, G. et al. Contribution of computational mechanics in numerical simulation of machining and blanking: State-of-the-Art. Arch Computat Methods Eng 13, 45–90 (2006). https://doi.org/10.1007/BF02905931

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02905931