Abstract

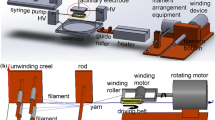

The possibility of producing blended yarn by using one spinneret is analyzed theoretically, especially the formation of differences in linear density and shrinkage between the monofils. Under the same spinning pressure, the die-spinning nozzles with different diameters are used to produce the differences in the flow of the melt. According to the hagen-poseuille equation for streamline flow in cylinder pipe, the volumetric flow rate and the mean melt speed of die-spinning nozzles increase with the increase of diameters. Under the conditions that the winding speeds are the same, so that the effective draw ratios decrease with the increase of the die-spinning nozzles diameters. Then, the filament formed through the die-spinning nozzle with large diameter is coarse and have a low birefringence. On the contrary, the filament formed through the die-spinning nozzle with small diameter is fine and have a high birefringence. The differences between the filament in structure and property could be acquired by one spinneret.

Similar content being viewed by others

References

X. Wang, Q. Feng, Y. Yao andet al., “The Production and Usage of the Silk-Like Fibers”, 1st ed., pp.48–60, China Petrifaction Press, Beijing, 1995.

A. B. Russian, Translated by Chenxi Ni Yipping, “The Manufacture and Usage of the Multi-Difference Yarn”, 1st ed., pp.1–11, China Textile Industry Press, Beijing, 1991.

X. Zhou and J. Xiao, “New Synthetic Fiber and Its Production”, 1st ed., pp.35–42, China Textile Press, Beijing, 1998.

L. Shi and C. Chen,Synthetic Technology & Application,9(2), 40 (1994).

X. Zhang, S. Meng, and Q. Zhao,China Synthetic Fibers, No. 6, 48 (1985).

M. Yao,Wool Technology, No. 4, 3 (2001).

H. Ian,Textile Horizons,12(6), 29 (1992).

X. Song, “Dyeing and Finishing of Shingson”, 1st ed., pp.50–55, China Textile Press, Beijing, 1997.

J. Okita and H. Miyake,Japan Patent, JP62-015320, 1987.

M. Yoshimoto and Y. Matsui,Japan Patent, JP59-094613, 1984.

K. Nose and K. Hori,Japan Patent, JP57-139515, 1982.

H. Otsubo and E. Ichihashi,Japan Patent, JP61-047815, 1986.

H. Iimuro, and O. Wada,Japan Patent, JP59-204972, 1984.

Y. Dai, P. Yuan, and Y. Zhang,China Synthetic Fiber Industry,14(5), 1 (1991).

K. Hayakawa,China Synthetic Fibers Industry,13(6), 1 (1990).

C. Li, H. Wang, X. Ma, andet al., China Synthetic Fiber Industry,22(5), 47 (1999).

C. Cao,China Synthetic Fiber Industry,13(5), 45 (1990).

X. Wang,Technical Fabrics, No. 6, 32 (1995).

Z. Hu, Ph.D. Dissertation, China Textile University, Shanghai, 1999.

C. Lai, Master Dissertation, China Textile University, Shanghai, 1998.

Y. Tong, X. Gao, and Z. Bi,China Synthetic Fiber Industry,15(6), 29 (1992).

J. Cheng,Technical Fabrics, No.2, 13 (1995).

G. K. Batchelor, “An Introduction to Fluid Dynamics”, 1st ed., pp.594–608, Cambridge Univ. Press, Cambridge, 1967.

Y. Zhang and B. Wang, “The Solution To A Problem of Fluid Dynamic”, 1st ed., pp.213–215, Beijing Institute of Technology Press, Beijing, 2001.

D. Guo and W. Wang, “The Science and Engineering of Polyester Fibers”, 1st ed., pp.177–180, China Textile Press, Beijing, 2001.

Y. Guo,China Synthetic Fiber, No. 1, 31 (1994).

F. Li, “Hydrodynamics and Hydro-Mechanism”, 1st ed., pp.210–226, Metallurgic Industry Press, Beijing, 1980.

X. Shen, X. Wu, Y. Li and J. Duo, “The Processing Principles for the High Molecular Materials”, 1st ed., pp.184–187, China Textile Press, Beijing, 2000.

A. Prastaron and P. Parrini,Text. Res. J.,46(2), 118 (1975).

Z. Wang, “Viscosity Fluid Dynamic”, 1st ed., pp.40–50, Publishing House of Harbin Industrial University, Harbin, 1990.

Z. Zhang and Z. Dong, “Viscosity Fluid Mechanics”, 1st ed., pp.65–66, Qinghua University Press, Beijing, 1998.

Y. Xu,China Synthetic Fibers, No. 6, 47 (1991).

T. Sun, H. Zhou, and X. Gao,China Synthetic Fibers, No.3, 20 (1979).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, N., Zhang, J., Lai, K. et al. Theoretic analysis on the manufacture of blended yarn by one spinneret. Fibers Polym 8, 284–288 (2007). https://doi.org/10.1007/BF02877271

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02877271