Abstract

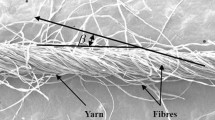

Roll drafting, a mechanical operation attenuating fiber bundles to an appropriate thickness, is an important operation unit for manufacturing staple yarns. It influences not only the linear density regularity of the slivers or staple yarns that are produced, but also the quality of the textile product and the efficiency of the thereafter processes. In this research, the dynamic states of the fiber bundle in the roll drafting zone were analyzed by simulation, based on the mathematical model that describes the dynamic behavior of the flowing bundle. The state variables are the linear density and velocity of the fiber bundles and we simulated the dynamics states of the bundle flow, e.g., the profiles of the linear density and velocity in the draft zone for various values of the model parameters and boundary conditions, including the initial conditions to obtain their influence on the dynamic state. Results showed that the mean velocity profile of the fiber bundle was strongly influenced by draft ratio and process speed, while the input sliver linear density has hardly affected the process dynamics. Velocity variance of individual fibers that could be supposed to be a disturbing factor in drafting was also influenced by the process speed. But the major disturbance occurred due to the velocity slope discontinuity at the front roll, which was strongly influenced by the process speed. Thickness of input sliver didn’t play any important role in the process dynamics.

Similar content being viewed by others

References

W. L. Balls, “Studies of Quality in Cotton”, MacMillan and Co., Ltd., London, p.122, 1928.

P. A. Grishin,J. Text. Inst.,45, 167 (1954).

J. S. Rao,J. Text. Inst.,52, 571 (1961).

H. R. Plonsker and S. Backer,Text. Res. J.,37, 637 (1967).

H. Balasubramanian, P. Grosberg, and Y. Turkes, “Studies in Modern Yarn Production”, Textile Institute, Manchester, p.150, 1968.

Y. Huh, “Modeling of Fiber Dynamics in Roller Draft”, the 6th ATC, Hong Kong, Aug. 22–24, 2001.

G. A. R. Foster and J. G. Martindale,J. Text. Inst.,37, T1 (1946).

J. S. Rao,J. Text. Inst.,53, T465 (1962).

B. Dutta and P. Grosberg,J. Text. Inst.,64, 534 (1973).

G. Mandl and H. Noebauer,J. Text. Inst.,68, 387, 394, 400 (1977).

N. A. G. Johnson,J. Text. Inst.,72, 69 (1981).

P. R. Lord and M. Govindaraj,J. Text. Inst.,81, 195 (1990).

G. Grover and P. R. Lord,J. Text. Inst.,83, 560 (1992).

Y. Huh and J. L. Woo,J. Korean Fiber Soc.,30, 527 (1993).

Y. Huh and J. S. Kim,Text. Res. J.,74, 872 (2004).

Y. Huh and J. S. Kim,J. Korean Fiber Soc.,41, 387 (2004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huh, Y., Kim, J.S. Effects of material parameters and process conditions on the roll-drafting dynamics. Fibers Polym 7, 424–431 (2006). https://doi.org/10.1007/BF02875776

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02875776