Abstract

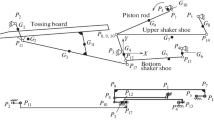

Samples of 28 different potato harvester chain links in seven different configurations were evaluated using the MSU-USDA Instrumented Sphere (IS). During the fall of 1989, 23 potato harvesters in Michigan were evaluated using the IS. Besides the IS impact data, each harvester was measured for chain speed relationships, operating ground speed, chain type and drop height. Testing of the harvesters did provide a range of data that represents what is likely to occur when the IS is used to evaluate individual harvesters. Based on the average peak acceleration and velocity change values (and the computed severity rating), air heads had the most severe impacts. The next most severe impacts were the primary chain, where all impacts were on steel. Next were the transitions to the rear cross and the side elevator, both of which involved a change of direction for the IS and the potatoes. Roller tables had the least severe impacts.

Compendio

Se evaluaron muestras de 28 diferentes eslabones de cadenas de cosechadoras, en siete diferente configuraciones, utilizando la Esfera Instrumentada de la MSU-USDA (IS). Durante el otoño de 1989, se evaluaron en Michigan 23 cosechadoras de papa utilizando la IS. Además de los datos sobre el impacto de la IS, cada cosechadora fué evaluada por sus relaciones con la velocidad de la cadena, su velocidad de operatión sobre el terreno, tipo de cadena y altura de descarga. Las pruebas con las cosechadoras proveyeron un rango de information que representa qué es lo que puede ocurrir cuando se utiliza la IS para evaluar a cada cosechadora por separado. Basándose en la aceleración máxima promedio y valores de cambio de velocidad (y la tasa computada de severidad), las cabeceras de aire tuvieron el impacto más severo. Los siguientes impactos más severos fueron sobre la cadena principal, donde todos los impactos fueron sobre acero. Los siguientes fueron en las conexiones con la cruceta posterior y el elevador lateral, los cuales provocan cambios de directión para la IS y las papas. Las mesas agitadoras tuvieron los impactos menos severos.

Similar content being viewed by others

Literature Cited

Brown, G.K., N.L. Schulte-Pason, E.J. Timm, C.L. Burton and D.E. Marshall. 1989. Apple packing line impact damage reduction. Tech. Paper 89-6050. ASAE, St. Joseph, MI.

Brown, G.K., N.L. Schulte-Pason and E.J. Timm. 1990. Impact classification using the instrumented sphere. Tech. Paper 90-6001. ASAE, St. Joseph, MI.

Fluck, R.C. and E.M. Ahmed. 1973. Impact testing of fruits and vegetables. Trans. ASAE 16:660–663.

Garcia, C., M. Ruiz and P. Chen. 1988. Impact parameters related to bruising in selected fruits. Tech. Paper 88-6027. ASAE, St. Joseph, MI.

Hesen, J.C. and E. Kroesbergen. 1960. Mechanical damage to potatoes. Eur Potato J 3:30–46.

Horsfield, B.C., R.B. Fridley and L.L. Claypool. 1972. Application of the theory of elasticity to the design of fruit harvesting and handling equipment for minimum bruising. Trans. ASAE 15:746–750.

Johnston, E.F. and J.B. Wilson. 1969. Effect of soil temperatures at harvest on the bruise resistance of potatoes. Am Potato J 46:75–82.

Mohsenin, N.N., V.K. Jindal and A.N. Manor. 1978. Mechanics of impact of a falling fruit on a cushioned surface. Trans. ASAE 21:594–600.

Peterson, C.L. and C.W. Hall. 1975. Dynamic mechanical properties of the Russet Burbank potato as related to temperature and bruise susceptibility. Am Potato J 52:289–312.

Schulte-Pason, N.L., E.J. Timm and G.K. Brown. 1990. Apple, peach and pear impact damage thresholds. Tech. Paper 90-6002. ASAE, St. Joseph, MI.

Siyami, S., H.R. Zapp, B.R. Tennes and G.K. Brown. 1987. Instrumented pseudofruit for acquisition of impact damage data for agricultural perishables. Rev Sci Instrum 58(7)1306–1310.

Thornton, R.E. 1985. Chain speed adjustment to obtain low tuber damage at harvest.In: Engineering for Potatoes, B.F. Cargill, Ed. ASAE, St. Joseph, MI.

Zapp, H.R., S.H. Ehlert, G.K. Brown, P.R. Armstrong and S.S. Sober. 1989. Advanced instrumentation sphere (IS) for impact measurement. Tech. Paper 89-6046. ASAE, St. Joseph, MI.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Brook, R.C. Impact testing of potato harvesting equipment. American Potato Journal 70, 243–256 (1993). https://doi.org/10.1007/BF02849312

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02849312