Abstract

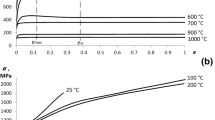

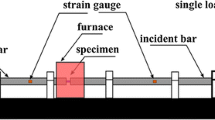

The deformation behavior of Ti-50.9 at % Ni shape memory alloy under axial compression dynamic loads was investigated by an MTS 858 Mini Bionix test machine. The alloy were aged at 500°C for an hour before being machined into specimens. The compression experiments were conducted at 20°C and the variety of dynamic loads were controlled by the strain rate, which was 3 mm/min, 15 mm/min, 30mm/min and 50 mm/min, respectively. The experimental results indicate that in the case of 3 mm/min, stress-induced martensitic transformation occurs at about 350 MPa when loading and reverse transformation at about 200 MPa when unloading, during which the aged Ti-50.9 at % Ni alloy shows the recoverable nonlinear pseudoelastic strain of 4.3% with the residual strain of 1.2% reserved. With the strain rate increasing, the area encloses by loading-curve and unloading-curve, i.e stress (strain) hysteresis becomes smaller and smaller and the residual strain also decreases, while critical stress for inducing martensitic transformation rises. At a higher strain rate the alloy exhibits linear-like pseudoelasticity, which is up to 4.5%.

Similar content being viewed by others

References

K Otsuka and C M Wayman.Shape Memory Materials. Cambridge, UK: Cambridge University Press, 1998:1–49

D Y Li. A New Type of Wear-resistant Material: Pseudo-elastic TiNi Alloy.Wear, 1998, 221:116–123

Tiancheng Zhang and D Y Li. An Experimental Study on the Erosion Behavior of Pseudo-elastic TiNi Alloy in Dry Sand and in Aggressive Media.Materials Science and Engineering, 2000, A293:208–214

H C Lin, S K Wu and M T Yeh. Damping Characteristics of TiNi Shape Memory Alloys.Metall. Trans. A, 1993, 24A:2189–2194

Murong Yang, Koshao Chen, Juichi Lee,et al. The Improvement of Biocompatibility of an Equiatomic TiNi Shape Memory Alloy by DC Plasma-polymerized Hexamethyldisilazane Coatings.Materials Science Forum, 2003, 426–432(4):3055–3060

Y F Zheng, W Cai, J X Zhang,et al. Microstructural Development inside the Stress Induced Martensite Variant in a Ti-Ni-Nb Shape Memory Alloy.Acta Mater., 2000, 48:1409–1425

Z G Wei, C Y Tang, W B Lee. Design and Fabrication of Intelligent Composites Based on Shape Memory Alloys.Journal of Materials Processing Technology, 1997, 69(1–3):68–74

Yu Haihu, Zhao Yu, Jiang Desheng. Development and Application of Smart Materials and Structure.Journal of Wuhan University of Technology, 2001, 23(1):37–41 (in Chinese)

Zhao Zhi-min, Chen Yu-ming, Yu Xiao-lei. The Parameters Selection of SMA Optically Activated and Its Application.journal of Wuhan University of Technology— Mater. Sci. Ed. 2002, 17 (4):1–4

H C Lin, S K Wu. The Tensile Behavior of a Cold-rolled and Reverse-transformed Equiatomic TiNi Alloy.Acta Metall. Mater., 1994, 42:1623–1630

T Tadaki, Y Nakata, K Shimizu. Thermal Cycling Effects in an Aged Ni-rich Ti-Ni Shape Memory Alloy.Trans. JIM, 1987, 28: 883–890

Jianming Gong and Tobushi Hisaaki. Superelastic Deformation Behavior of TiNiShape Memory Alloy Subjected to Various Cyclic Loading.Journal of Functional Materials, 2002, 33(4):391–397 (in Chinese)

P Filip and K Mazanec. Influence of Work Hardening and Heat Treatment on the Substructure and Deformation Behaviour of Ti-Ni Shape Memory Alloys.Scripta Metall. Mater., 1995, 32(9): 1375–1380

Khalil Allafi J, Ren X, Eggeler Gunther. The Mechanism of Multistage Martensitic Transformations in Aged Ni-rich NiTi Shape Memory Alloys.Acta Materialia, 2002, 50(4):793–803

X L Lu, W Cai and L C Zhao. Damping Behavior of a Ti44 Ni47 Nb9 Shape Memory Alloy.Journal of Materials Science Letters, 2003, 22:1243–1245

M. Fremond and S Miyazaki.Shape Memory Alloys. Springer Verlag Wion. New York, 1996, 95

H C Lin, H M Liao, J E He,et al. Wear Characteristics of TiNi Shape Memory Alloys.Metall. and Mater. Trans. A, 1997, 28A: 1871–1877

Author information

Authors and Affiliations

Additional information

HUANG Xue-wen: Born in 1972

Funded by the National Natural Science Foundation of China (No. 50075072) and the Open Foundation of Tribology Institute of Southwest Jiaotong University

Rights and permissions

About this article

Cite this article

Xue-wen, H., Guang-neng, D., Zhong-rong, Z. et al. The deformation behavior of TiNi shape memory alloy under axial dynamic compression. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 19, 86–89 (2004). https://doi.org/10.1007/BF02835070

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02835070