Abstract

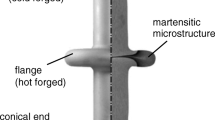

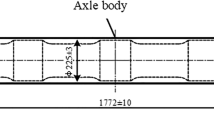

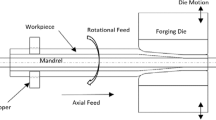

Forging processes in the past have primarily been developed based on empirical relationships or trial and error. The finite element approach to forging process development and design has been found to be practically feasible and economical. The rigid-viscoplastic finite element method (FEM) code “ALPID” developed by Battelle Columbus Laboratories, has been successfully utilized to simulate metal forming processes. In the following paper, the application of finite element simulation to study deformation mechanics in the forging of gear blanks and axle shafts is discussed. An underfill problem on the gear blank was overcome and tool life was improved on the axle shaft hot heading process.

Similar content being viewed by others

References

Oh, S.I., Lahoti, G.D., and Altan T., ALPID—A General Purpose FEM Program for Metal Forming, Proceedings of NAMRC IX, May 1981, State College, PA, p. 83.

Oh, S.I., Finite Element Analysis of Metal Forming Problems with Arbitrarily Shaped Dies,Int. J. of Mech. Sciences, v. 24, No. 4, p. 479.

Oh, S.I., Lahote, G.D., and Altan, T., Analysis of Backward Extrusion Processes by FEM, Proceedings of NAMRC, p. 143, May 1982.

Oh, S.I., Park, J.J., Kobayashi, S., and Altan, T., Application of FEM Modeling to Simulate Metal Flow in Forging a Titanium Alloy Engine Disk, Trans. of ASME,J. of Eng. of Industry, November 1983, v. 105, p. 251.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Duggirala, R., Badawy, A. Finite element method approach to forging process design. J. Mater. Shaping Technol. 6, 81–89 (1988). https://doi.org/10.1007/BF02834823

Issue Date:

DOI: https://doi.org/10.1007/BF02834823