Abstract

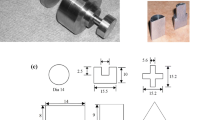

This study investigates the influence of weld cavity geometry on metal flow during the extrusion process. The results of physical modeling done with lead billets are presented. A method of weld cavity design that ensures uniform metal flow in extrusion of asymmetric shapes is proposed.

Similar content being viewed by others

References

J. Wantuchowski, J. Richert:Rudy Metale, 1972, vol. 5, pp. 219–223 (in Polish).

J. Wantuchowski, J. Zasadzinski, J. Richert:Metalurgia Odlewnictwo, 1974, No 438(59), pp. 259–273 (in Polish).

J. Zasadzinski et al.: Report, Part I and II, IPPiM, The Academy of Mining and Metallurgy, Krakow, 1983, 1984 (in Polish).

J. Zasadzinski, J. Richert, W. Misiolek: Proceedings of XI Report Meeting of Metalurgical Committee of Polish Academy of Sciences, Kozubnik, Poland, October 6–9, 1987, pp. 145–148 (in Polish).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zasadzinski, J., Richert, J. & Misiolek, W. Physical modeling pertaining to extrusion of asymmetric shapes. J. Materials Shaping Technology 7, 113–116 (1989). https://doi.org/10.1007/BF02833777

Issue Date:

DOI: https://doi.org/10.1007/BF02833777