Abstract

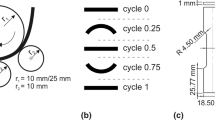

A study has been made of “side-wall curl” in a series of low-carbon, HSLA 50 and 80 and DP-80 steels. “Curl” occurs when the sheet metal is drawn into a die cavity, as in the forming of hat-shaped sections. It is found that the curl increases with increasing tensile strength and decreasing thickness of the steels, and that there is no consistent variation of curl with die radius. However, the curl, which is a consequence of residual stresses generated by the forming process, is thought to be influenced by the strain-hardening rate of the material, since this will affect the strain distribution through the sheet thickness. It is shown that, by the imposition of plastic deformation, the curl can be eliminated, as the result of the removal of the nonuniform distribution of residual stresses.

Similar content being viewed by others

References

R.G. Davies and C.L. Magee:J. Met., 1979, vol. 31, no. 11, pp. 17–23.

M. S. Rashid: SAE Preprint Numbers 760206, February 1976.

R.G. Davies:J. Appl. Metalwork., 1981, vol. 1, pp. 45–52.

George E. Dieter, Jr.,Mechanical Metallurgy, 1st ed., p. 417, McGraw-Hill Book Company, New York, 1961.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Davies, R.G. “Side-wall curl” in high-strength steels. J. Applied Metalworking 3, 120–126 (1984). https://doi.org/10.1007/BF02833690

Issue Date:

DOI: https://doi.org/10.1007/BF02833690