Abstract

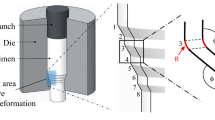

The workability of a material during deformation processing is determined by (a) the die geometry which, in turn, determines the flow field during deformation, and, (b) the inherent workability of the material under the imposed processing conditions of strain rate and temperature. Most common alloys have good inherent workability and can be successfully formed over wide ranges of temperature and strain rate. Products can be successfully formed from these alloys even with dies which impose large variations in strain rate during deformation. However, many of the new alloys and composites can be deformed only in very narrow processing regimes, and control of the strain rate during deformation of such materials becomes important. For example, extrusion of a whisker-reinforced aluminum alloy composite is possible only when the strain rate is controlled to within one order of magnitude. This paper describes the development of a method for obtaining preliminary shapes of controlled strain rate extrusion dies, a special case being the constant strain rate die. The theoretical basis for such die design processes is presented, followed by some examples of die geometries. Since this design procedure ignores the material flow properties, the designed die shapes must be verified using the finite element method or physical modeling. Results of simulations with the program ALPID are also presented.

Similar content being viewed by others

References

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker, “Modeling of Dynamic Materials Behavior in Hot Deformation: Forging of Ti 6242,”Met. Trans. 15A, p. 1883 (1984).

Y.V.R.K. Prasad, H.L. Gegel, J.C. Malas, J.T. Morgan, K.A. Lark, S.M. Doraivelu, and D.R. Barker, “Constitutive Behavior and Dynamic Modeling of Hot Deformation of a P.M 2024 Al Alloy with 20 Vol.% SiC Dispersion,” Technical Report AFWAL-TR-84-4076, Air Force Wright Aeronautical Laboratories, Wright-Patterson AFB, November 1984.

J.C. Malas, H.L. Gegel, J.S. Gunasekera, S.M. Doraivelu, and J.T. Morgan, “Computer-Aided Design of Extrusion Dies by Metal-Flow Simulation,” inComputers in Engineering 1983 American Society of Mechanical Engineers, New York, 1983.

H.L. Gegel, J.S. Gunasekera, J.C. Malas, J.T. Morgan, and L.E. Matson, “Consolidation and Forming of P/M Porous Billets,” inRapid Solidification Processing Principles and Technologies, III, R. Mehrabian, Ed., National Bureau of Standards, Washington, D.C., 1982.

J.C. Malas, J.T. Morgan, H.L. Gegel, J.S. Gunasekera, S.M. Doraivelu, and S.I. Oh, “An Investigation on the Mathematical Modeling Technique used for Analyzing Industrial Metal-working Processes,” in11th North American Manufacturing Research Conference Proceedings, North American Manufacturing Research Institute of SME, Dearborn, Michigan, 1983, pp. 203–210.

J.S. Gunasekera and S. Hoshino, “Extrusion of Non-Circular Sections through Shaped Dies,”Annals Intl. Inst. Prod. Eng. Res. (C1RP) 29, p. 141, 1980.

V. Nagpal and T. Altan, “Computer-Aided Design and Manufacturing of Dies for Lubricated Extrusion of Shapes,”J. Mech. Working Tech. 1, 183, 1978.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Srinivasan, R., Gunasekera, J.S., Gegel, H.L. et al. Extrusion through controlled strain rate dies. J. Materials Shaping Technology 8, 133–141 (1990). https://doi.org/10.1007/BF02833625

Issue Date:

DOI: https://doi.org/10.1007/BF02833625