Abstract

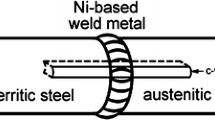

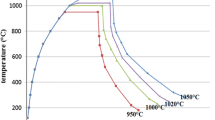

The effect of postweld heat treatments (PWHT) and hydrogen charge on disbonding susceptibility of type 347 weld overlays on 2.25Cr-lMo base material was studied. Following PWHTs at 690° C (ASME code requirements) high disbonding susceptibilities were found. Martensitic bands were formed during welding at the cladding interface. During PWHT at 690° C, these bands have been reaustenitized and massive carbide precipitation took place in regions closest to the parent metal. Carbide precipitation involved austenite destabilization during cooling from PWHT and local formation of virgin martensite. The presence of high hydrogen contents and of tensile residual stresses in interfacial regions of the clad resulted in a heavy local loss of ductility and disbonding occurrence. In order to reduce the disbonding susceptibility, temperatures not exceeding 600° C should be reached during PWHT, so that the reaustenitization of cladding interfacial regions can be avoided and more favorable stress and hydrogen distributions be obtained locally. A reduced disbonding susceptibility can be obtained on samples heat treated at 690° C only if a final heat treatment at 590° C is superimposed, confirming the importance of structural evolution during PWHT in influencing resulting residual stresses and hydrogen distributions.

Similar content being viewed by others

References

K. Naito and K. Kinoshita. Final Report, the Japan Pressure Vessel Research Council, 1982, p. 1.

J.E. Sims and G.J. Bruck. Chicago Bridge and Iron Company, Houston, Texas, p. 34.

T. Badino and G. Camona. Proc. Riporti con Saldatura, Chiavari, 1984.

S. Talbot,Mem. Sc. Rev. Met., 5, 1979, p. 301.

R.A. Oriani and P.H. Josephic.Acta Met., 27, 1979, p. 997.

S. Hannula, H. Hanninen, and S. Tahtinen,Met. Trans. A, 15, 1984, p. 2205.

M. Balbi,L’acciaio Inossidabile, 3, 1983, p. 18.

M.F. Gittos, J.L. Robinson, and T.G. Gooch. “Disbonding of Austenitic Stainless Steel Cladding in High Temperature Hydrogen Service,” The Welding Institute, Summary Report, March 1984, pp. 6–7.

H.A. Schimoeller and J.L. Ruge. Proc. Int. Conf. Residual Stresses in Welded Construction and Their Effects, The Welding Institute, Nov. 1977, p. 251.

M. Habashi, and J. Galland.Mem. Sc. Rev. Metal., 6, 1982, p. 316.

N. Bandyopadhyay, K. Jun, and C.J. McMahon.Met. Trans., 14A, 1983, p. 881.

D.L. Johnson, G. Krauss, J.K. Wu, and K.P. Tang,Met. Trans., 18A, 1987, p. 718.

J.P. Hirt,Met. Trans., 11A, 1980, p. 861.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

De Sanctis, M., Paganini, L., Solina, A. et al. Disbonding of type 347 weld overlays induced by postweld heat treatments and hydrogen charge. J. Heat Treating 7, 35–47 (1989). https://doi.org/10.1007/BF02833186

Issue Date:

DOI: https://doi.org/10.1007/BF02833186