Abstract

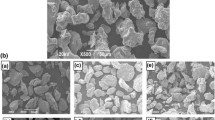

The spray-dispersion method, which produces a metal containing homogeneously dispersed fine oxide particles sprayed from outside into the molten metal stream, was applied to HASTELLOY* X and Ni−Cr−W alloy. The condition of the dispersion of ZrO2 particles and the mechanical properties were examined for ZrO2 dispersed alloys. The addition of a dispersion controlling element, Nb or Ta, was found to be effective for decreasing the average particle diameter of sprayed particles and for increasing the volume fraction of the particles. Ultimate tensile strength and 0.2 pct proof strength were increased by ZrO2 particle dispersion. And creep strength of ZrO2 particle dispersed alloys was greater than that of non-dispersed ones. From these results, the production of oxide dispersed nickelbase heat resistant alloys has been established by the spray-dispersion method.

Similar content being viewed by others

References

M. Hasegawa and K. Takeshita:Metall. Trans. B, 1978, vol. 9B, pp. 383–88.

M. Hasegawa and K. Takeshita:Tetsu-to-Hagané, 1977, vol. 63, pp. 294–302.

M. Hasegawa and K. Takeshita:Report of the 123rd Committee on Heat-Resisting Metals and Alloys, Japan Society for the Promotion of Science, 1977, vol. 18, pp. 201–06.

M. Hasegawa, K. Sassa, and K. Sekine:Report of the 123rd Committee on Heat-Resisting Metals and Alloys, Japan Society for the Promotion of Science, 1978, vol. 19, pp. 213–18.

M. Hasegawa, K. Takahashi, and S. Watanabe:Tetsu-to-Hagané, 1982, vol. 68, pp. 1024–31.

M. Hasegawa: Waseda University, Tokyo, Japan, unpublished research, 1982.

M. Hasegawa:Spray-Dispersion Strengthening of Metals, The Nikkan Kogyo Shinbun-sha, Ltd (Industrial Daily News, Ltd), Tokyo, 1980, pp. 129–31.

M. Hasegawa and K. Takeshita:Tetsu-to-Hagané, 1976, vol. 62, pp. 201–09.

W. M. Armstrong, A. C. D. Chaklader, and J. F. Clarke:J. Amer. Ceramic Soc., 1962, vol. 45, pp. 115–18.

V. I. Tumanov, V. F. Funke, and L. I. Belen'kaya:Zh. Fiz. Khim., 1962, vol. 36, pp. 1574–77.

S. Ohta:Tetsu-to-Hagané, 1979, vol. 65, pp. 1031–40.

R. Raj and M. F. Ashby:Metall. Trans. A, 1972, vol. 3, pp. 1937–42.

T. Tanabe, T. Shikata, Y. Sakai, Y. Fujitsuta, H. Araki, H. Yoshida, and R. Watanabe:Tetsu-to-Hagané, 1983, vol. 67, pp. 2045–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hasegawa, M., Osawa, M. Oxide dispersion strengthened nickel-base heat resistant alloys by means of the spray-dispersion method. Metall Trans A 16, 1043–1048 (1985). https://doi.org/10.1007/BF02811674

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02811674