Abstract

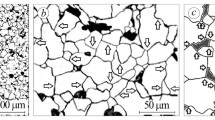

We investigate the resistance to hydrogen-sulfide stress corrosion cracking and hydrogen-induced cracking of ASTM A333 steel intended for the oil and gas industry. On the basis of the results obtained for seven meltings of this steel supplied for the Tengiz gas-processing plant, we established that all meltings satisfy specifications of the NACE MR0175-96 standard in their chemical composition and strength characteristics (S < 0.005%. P < 0.025%, HRC < 22, etc.). For two of the seven investigated meltings, resistance to hydrogen-sulfide stress corrosion cracking is not high (threshold stresses < 0.8Σmin 0.2) and one melting has a low resistance to hydrogen-induced cracking (coefficient of the length of regions of crack formation > 6% and coefficient of the width of regions of crack formation > 3%). Therefore, complete (100%) incoming control over the corrosion-mechanical resistance of all materials of equipment operating in hydrogen-sulfide-containing media must be carried out.

Similar content being viewed by others

References

A. I. Radkevich. V. P. Koval’, T. N. Kalichak. and I.I. Vasilenko, “Corrosion cracking of martensite rustless steels in hydrogen-sul-containing media.”Kor. Zashch. Neftegaz. Prom., No. 11, 3–5 (1974).

A. I. Radkevich, 0. N. Chaplya, and I.I. Vasilenko, “The corrosion-electrochemical behavior of stainless steels in hydrogen-sulfide-containing media.”Kor. Zashch. Neftegaz. Prom., No. 5, 2–4 (1981).

A. I. Radkevich. M. D. Klapkiv, T. S. Dolotova. and I.I. Vasilenko. “The influence of the composition of a hydrogen-sulfide-containing medium on the growth rate of a crack under cyclic loading.”Fiz.-Khim. Mekh. Mater.,20, No. 3, 29–32 (1984).

V. G. Sorokin (editor),A Handbook of Types of Steels and Alloys [in Russian], Mashinostroenie. Moscow (1989).

NACE Standard MR0I75-96.Standard Material Requirements. Sulfide Stress Cracking Resistant Metallic Materials for Oilfield Equipment. NACE, Houston P. O. Box 218340 (1996).

Specification Tenguiz Oil and Gas Plant. Process Plant, Lurgi code: 65102-00-MAL — TENGUIZ II. Specification No. SPC- 62900-XP-007.

NACE Standard TM-01-77.Standard Test Method. Testing of Metals for Resistance to Sulfide Stress Cracking at Ambient Temper- atures, NACE. Houston P. O. Box 1499 (1977).

MSKR-01-85. AMethod for Tests for Resistance to Hydrogen-Sulfide Corrosion Cracking [in Russian], GKNT SSSR. Moscow (1985).

NACE Standard TM-02-84.Test Method Evaluation of Pipeline Steels for Resistance to Stepwise Cracking, Houston. Texas (1984).

M. F. J. Galis. B. J. Orlans, and G. C. Guntz.Study of Metallurgical Parameters Influencing the Behaviour of Line Pipes in H,SMedium, SSC Symposium. Saint-Cloud (1991).

D. Brideau. M. Lafrance. and I. Proveau. Development of New Sorts of Steel with Increased Characteristic for Transport of Acid Gas and Oil [in Russian], in:Neftegaz-Frantsiya, Yuzinor As e., Moscow (1986).

G. M. Pressoure. R. Blondeau, and L. Cadiou, “HSLA steels with improved hydrogen sulfide cracking resistance.” in:Proc. Conf. Amer. Soc. Metals, Philadelphia (1984), pp. 827–843.

I. I. Vasylenko. O. Yu. Shul’te, and O. I. Radkevich. “The influence of the chemical composition and technology of production of steels on their sensitivity to hydrogen-induced cracking and hydrogen-sulfide stress corrosion cracking.”Fiz.-Khim. Mekh. Mater.,26. No. 4. 8–22(1990).

T. Kaneko. U. Okada. and A. Ikeda. The Influence of the Microstructure on the Sensitivity to SSC of Low-Alloy High-Strength Pipe Products for Oil-Extracting Countries, in:Pipes of Oil Range and Pipe-Line Industry of Sumitomo, I-2-1, Sumitomo, Tokyo (1989).

A. I. Radkevich. R. K. Melekhov, Ya. I. Spektor. and R. V. Yatsenko. “Investigation of domestic and foreign low-alloy hydrogen-sulfide-resistant steels for oil and gas pipe-line equipment,” in:Proceedings of the International Scientific and Engineering Conf. “StructuralSteels-Progressive Processes of Production and Efficiency of Applications” (Dnepropetrovsk. October 1995) [in Russian], Dnepropetrovsk (1995), pp. 58–59.

O. Chaplya. O. Radkevych, O. P’yasets’kyi. and Ya. Spektor, “Comparative analysis of corrosion-mechanical characteristics of do- mestic 20YuCh pipe steel with its foreign analogs,”Mashynoznavsn’o, No. 8, 52–56 (1999).

Author information

Authors and Affiliations

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv. Vol. 36, No. 3, pp. 93–97, May-June. 2000.

Rights and permissions

About this article

Cite this article

Radkevych, O.I., P’yasets’kyi, O.S. & Vasylenko, I.I. Corrosion-mechanical resistance of pipe steel in hydrogen-sulfide containing media. Mater Sci 36, 425–430 (2000). https://doi.org/10.1007/BF02769606

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02769606