Abstract

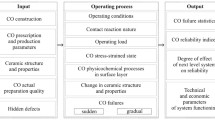

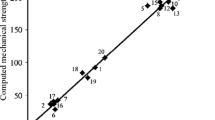

Problems arising in designing and organizing ceramics production, including a new generation of materials, are formulated and differentiated. Some aspects of the properties of the materials are described using deterministic, statistical, and probabilistic models. The latter two models are shown to be expedient and promising. It is shown that the effect of the manufacturing process should be taken into account when evaluating the operating properties of the products.

Similar content being viewed by others

References

P. O. Gribovskii.Hot Casting of Ceramic Parts [in Russian], Gosénergoizdat, Moscow-Leningrad (1961).

K. K. Strelov,Structure and Properties of Refractories [in Russian], Metallurgiya, Moscow (1972).

V. L. Balkevich, “Ceramics of a new generation,”Steklo Keram., No. 6, 17–20 (1988).

K. K. Strelov,Theoretical Fundamentals of the Technology for Refractory Materials [in Russian], Metallurgiya, Moscow (1985).

P. A. Kouzov,Basic Principles for Analyzing the Disperse Composition of Industrial Dust and Ground Materials [in Russian], Khimiya, Leningrad (1987).

K. Okadzaki,The Technology of Ceramic Dielectrics [Russian translation], Énergiya, Moscow (1976).

E. B. Bendovskii and Yu. M. Mosin, “Effect of the shaping method on the strength properties of ceramics,”Steklo Keram., No. 11-12, 27–29 (1992).

H. Liebowitz (ed.),Fracture, Vol. 7, Microscopic and Macroscopic Fundamentals, Academic Press, New York (1969).

V. E. Vernikovskii, “Calculating the parameters of the equation of unloading and multiple compaction in semidry pressing of refractory parts,”Ogneupory, No. 6, 17–21 (1990).

A. K. Karklit, A. P. Larin, S. A. Losev, and V. E. Vernikovskii,Production of Refractories by the Semidry Method [in Russian], Metallurgiya, Moscow (1981).

V. E. Perel'man,Shaping of Powder Materials [in Russian], Metallurgiya, Moscow (1979).

R. Ya. Popil'skii and Yu. E. Pivinskii,Pressing of Powder Ceramic Mixtures [in Russian], Metallurgiya, Moscow (1983).

S. P. Nichiporenko,Fundamental Problems of the Theory of Processing and Shaping of Ceramic Mixtures [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1960).

Yu. M. Rappoport, “Ultrasound flaw detection for refractory products,”Ogneupory, No. 11, 24–29 (1985).

S. L. Akhnazarova and V. V. Kafarov,Optimization of Experiments in Chemistry and Chemical Engineering [in Russian], Vysshaya Shkola, Moscow (1978).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 4, pp. 8–12, April, 1998.

Rights and permissions

About this article

Cite this article

Mosin, Y.M. Some problems of the development of technology and science of ceramics and refractories. Refract Ind Ceram 39, 121–124 (1998). https://doi.org/10.1007/BF02768037

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02768037