Abstract

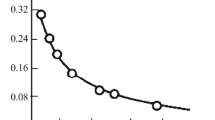

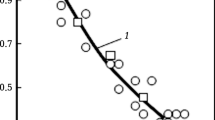

Refined estimates of the efficiency of sintering were obtained using various structural models of ceramic materials. The most precise method is based on a special model developed by the author for the structure of powdered materials and an approximation according to which the Voronoi polyhedra are assumed to remain unchanged on decreasing the porosity of the system, while the pore volume decreases owing to an apparent increase in the particle diameter.

Similar content being viewed by others

References

K. K. Strelov,Structure and Properties of Refractories [in Russian], Metallurgiya, Moscow (1972).

W. H. Rhodes, “Agglomerate and particle size effects on sintering yttria-stabilized zirconia,”J. Amer. Ceram. Soc.,64(1), 19–22 (1981).

V. V. Skorokhod and Yu. M. Solonin, “The ratio of integral and local densification during sintering of porous solids,”Poroshk. Metall., No. 12, 25–30 (1983).

V. V. Skorokhod, Yu. M. Solonin, and I. V. Uvarova,Chemical, Diffusion, and Rheological Processes in the Technology of Powder Materials [in Russian], Naukova Dumka, Kiev (1990).

V. A. Ivensen, “Study of the densification of metalloceramic composites on sintering. VI. The difference in the behavior of amorphous and crystalline (metallic) porous solids on sintering,”Zh. Tekh. Fiz., No. 4, 677–685 (1952).

O. J. Whittemore and S. A. Varela, “Pore distributions and pore growth during the initial stages of sintering,” in:Proc. 5th Conf. on Sintering and Related Phenomena, Notre Dame (1979), pp. 18–46.

L. A. Vermenko, O. I. Konovalyuk, and S. M. Solonin, “The phenomenon of pore size growth during activated sintering of tungsten powders,” in:Disperse Crystalline Powders in Materials Science [in Russian], Inst. Probl. Materialoved., Kiev (1980), pp. 126–128.

Yu. N. Kryuchkov, “Structural model of monodisperse powder materials,”Poroshk. Metall., No. 9-10, 66–72 (1993).

Yu. N. Kryuchkov, “Porous structure of ceramic materials based on monodisperse powders,”Steklo Keram., No. 5-6, 33–35 (1994).

E. Arzt, “The influence of an increasing particle coordination on the densification of spherical powders,”Acta Metallurgica,30(10), 1883–1890 (1982).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 4, pp. 34–36, April, 1997.

Rights and permissions

About this article

Cite this article

Kryuchkov, Y.N. Evaluation of the efficiency of sintering of porous ceramic materials. Refract Ind Ceram 38, 164–167 (1997). https://doi.org/10.1007/BF02767932

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767932