Abstract

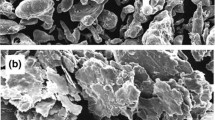

The kinetics of grain growth in compacts made of submicron titanium powders obtained by controlled hydrolysis of titanium alcoholates was studied. It was established that inhomogeneous packing of the particles in a compact made of agglomerated powder stimulates intense grain growth even in the early stage of sintering. It is shown that a material obtained by sintering homogeneously packed compacts composed of coarse non-agglomerated particles possesses, despite a low density, a homogeneous highly disperse structure and exhibits a much higher strength than a material obtained upon sintering a finely divided but agglomerated powder to maximum density.

Similar content being viewed by others

References

K. W. Lay, “Grain growth during sintering,”Mat. Sci. Res., No. 6, 66–80 (1973).

C. Greshkovich and K. W. Lay, “Grain growth in very porous Al2O3 compacts,”J. Amer. Ceram. Soc. 55(3), 142–146 (1972).

M. Yu. Bal’shin,Physical Powder Metallurgy [in Russian], Metallurgiya, Moscow (1948).

E. A. Barringer and H. K. Bowen, “Formation, packing and sintering of monodisperse TiO2 powders,”J. Amer. Ceram. Soc.,65(12), C-199–C-201 (1982).

T. K. Gupta, “Possible correlation between density and grain size during sintering,”J. Amer. Ceram. Soc. 55(5), 276–277 (1972).

A. V. Galakhov and I. V. Vyazov, “Compacting and sintering of agglomerated ultradisperse powders,”Ogneupory, No. 9, 12–16 (1989).

A. V. Galakhov and N. M. Zhavoronkov, “Pore size distribution and the formal analysis of sintering kinetics,”Dokl. Akad. Nauk SSSR,316(6), 1444–1446 (1991)

F. F. Lange and B. J. Kellett, “Thermodinamics of densification. Part II. Grain growth in porous compacts and relation to densification,”J. Amer. Ceram. Soc.,72(5), 735–741 (1989).

M. F. Yan, R. M. Cannon, H. K. Bowen, and U. Chowdhry, “Effect of grain size distribution on sintered density,”Mater. Sci. Eng.,60, 275–281 (1983).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 4, pp. 18–22, April, 1997.

Rights and permissions

About this article

Cite this article

Galakhov, A.V., Tsibailo, E.V., Yanovskaya, M.I. et al. Grain growth during the sintering of compacted submicron powders. Refract Ind Ceram 38, 147–151 (1997). https://doi.org/10.1007/BF02767926

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767926