Abstract

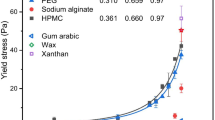

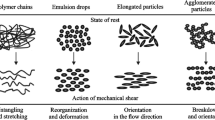

The effects of various factors, including the characteristics of the solid phase, bulk concentration, stabilization, coagulation, temperature, and vibrations, on the dilatant properties of high-density ceramic binding suspensions are considered. The main factor controlling the dilatancy is the proximity of the actual bulk concentrationC v to the critical valueC v cr, corresponding to the concentration of shape formation (conversion of the suspension into a solid). Suspensions of quartz glass withC v cr=0.91 possessed a Newtonian character of flow forC v=0.75−0.78, while suspensions withC v cr=0.70−0.75 exhibited a strong dilatancy even in the range ofC v=0.60−0.64. The dilatancy of some highly disperse suspensions at much lower values ofC v is caused by a high value of the effective bulk concentrationC v ef, including a considerable volume of bound liquid. On the basis of results of original studies and generalization of published data, a mechanism is formulated according to which dilatancy is treated as due to the effect of constrained volume in disperse systems. Most suspensions are characterized by a bulk dilatancy according to Reynolds.

Similar content being viewed by others

References

Yu. E. Pivinskii, “Rheology in the technology of ceramics and refractories. Part 5. Dilatancy: classification and types of dilatant systems,”Ogneupory, No. 2, 8–16 (1997).

Yu. E. Pivinskii,Ceramic Binders and Ceramic Concretes [in Russian], Metallurgiya, Moscow (1990).

Yu. E. Pivinskii, “On the thixotropy and dilatancy of ceramic suspensions of fused quartz,”Zh. Prikl. Khim. 45(9), 1917–1922 (1972).

Yu. E. Pivinskii, “Rheological and sedimentation properties of ceramic suspensions with granulated fillers,”Ogneupory, No. 4, 52–57 (1972).

Yu. E. Pivinskii, “Rheological properties of aqueous silica gel suspensions,”Kolloidn. Zh.,35(2), 289–295 (1973).

Yu. E. Pivinskii, “Study of dilatancy in mineral suspensions of various concentrations,”Fiz.-Khim. Mekh. Liof. Disp. Sistem, No. 6, 182–187 (1974).

N. N. Kruglitskii and Yu. E. Pivinskii, “On classification of the types of rheological behavior of dilatant disperse systems,”Dokl. Akad. Nauk UkrSSR, Ser. B, No. 3, 258–261 (1974).

Yu. E. Pivinskii and R. G. Makarenkova, “The effect of granulated filler on the rheological properties of ceramic suspensions,”Ogneupory, No. 12, 39–44 (1978).

Yu. E. Pivinskii, “Study of the rheological and binding properties of quartz sand suspensions,”Ogneupory, No. 6, 39–45 (1980).

Yu. E. Pivinskii and P. L. Mityakin, “Rheological and binding properties of high-silica-gel suspensions,”Ogneupory, No. 5, 48–52 (1981).

V. A. Bevz and Yu. E. Pivinskii, “Obtaining binding suspensions and ceramic concretes based on dinas,”Ogneupory, No. 9, 46–51 (1981).

N. N. Kruglitskii and Yu. E. Pivinskii, “Effect of stabilization and coagulation on the dilatancy of mineral suspensions,”Khim. Tekhnol., No. 1, 22–24 (1981).

Yu. E. Pivinskii, “On the phase relations, important technological properties, and classification of ceramic and other binder systems,”Ogneupory, No. 6, 49–60 (1982).

Yu. E. Pivinskii, “Volumetric and phase characteristics and their effect on the properties of suspensions and ceramic mold systems,”Ogneupory, No. 11, 50–58 (1982).

Yu. E. Pivinskii, “On the stabilization and aging of ceramic suspensions,”Ogneupory, No. 8, 15–22 (1983).

Yu. E. Pivinskii, N. T. Kotova, and F. S. Kaplan, “Highly concentrated suspensions of nontransparent quartz glass and related materials,”Ogneupory, No. 6, 14–19 (1986).

Yu. E. Pivinskii, “Highly concentrated ceramic binding suspensions. Principles of technology,”Ogneupory, No. 10, 3–9 (1987).

Yu. E. Pivinskii, “Highly concentrated ceramic binding suspensions. Stabilization, rheological properties, and principles of rheotechnological compatibility,”Ogneupory, No. 6, 6–13 (1988).

F. S. Kaplan and Yu. E. Pivinskii, “Rheological and colloidal-chemical properties of ceramic disperse systems,” in:Chemistry and Technology of Silicate and Refractory Nonmetallic Materials [in Russian], Nauka, Leningrad (1989), pp. 125–141.

F. S. Kaplan, Yu. E. Pivinskii, and A. N. Saprykin, “On the features of dilatant strengthening of quartz glass suspensions,”Kolloidn. Zh.,50(6), 1092–1098 (1988).

F. S. Kaplan and Yu. E. Pivinskii, “Study of the effect of dispersion composition on the rheological properties of highly concentrated silica gel suspension,”Kolloidn. Zh.,54(4), 73–79 (1992).

Yu. E. Pivinskii, “Refractory concretes of a new generation. Colloidal-chemical aspects of the technology,”Ogneupory, No. 1, 4–12 (1994).

Yu. E. Pivinskii, “Refractory concretes of a new generation. Rheological aspects of the technology,”Ogneupory, No. 4, 6–14 (1994).

H. Freudlich and H. L. Roder, “Thixotropy and dilatancy,”Trans Faraday Soc.,34(202), 308–316 (1938).

W. H. Bauer and E. A. Collins, “Thixotropy and dilatancy,”Rheology. Theory and Applications,IV(4), 423–459 (1967).

A. B. Metzner and M. Whitlok, “Factors influencing dilatant behavior of suspensions,”Trans. Soc. Rheol.,2(2), 239–247 (1958).

M. K. Gal’perina and N. V. Kolyshkina, “Study of the rheological properties of clay slips,”Trudy Gos. NIIStroikeramika, No. 53, 5–16 (1983).

I. F. Efremov, G. M. Lukashenko, and É. A. Terent’eva, “The formation and properties of periodic colloidal structures,” in:Surface Forces in Thin Films [in Russian], Nauka, Moscow (1979), pp. 20–29.

I. F. Efremov, G. M. Lukashenko, and É. A. Terent’eva, “Dilatancy of colloidal structures,”Kolloidn. Zh.,42(5), 859–866 (1980).

I. F. Efremov, “Dilatancy of colloidal structures and polymer solutions,”Usp. Khim,51(2), 285–310 (1982).

A. P. Tikhonov, O. V. Senatova, and A. F. Krivoshchepov, “Study of the properties of Al2O3 suspensions for the production of ceramic ware by electrophoretic techniques,”Kolloidn. Zh.,38(5), 1022–1025 (1976).

A. P. Tikhonov and A. F. Krivoshchepov, “Effect of the dispersity of the solid phase on the structural-mechanical properties of highly concentrated suspensions,”Kolloidn. Zh.,41(2), 383–386 (1979).

A. P. Tikhonov and A. F. Krivoshchepov, “Dilatant-thixotropic transformations in periodic colloidal structures,”Kolloidn. Zh.,41(5), 1212–1213 (1979).

Yu. E. Pivinskii and A. G. Romashin,Quartz Ceramics [in Russian], Metallurgiya, Moscow (1974).

Yu. E. Pivinskii and A. I. Natsenko, “Rheological and technological properties of mixed suspensions based on refractory components,”Ogneupory, No. 11, 49–55 (1974).

L. I. Peregudova, A. V. Akol’zina, N. B. Ur’ev, et al., “Colloidal-chemical properties of zinc-silicate compositions,”Kolloidn. Zh.,57(5), 709–712 (1995).

K. M. Beazleu, “Factors influencing dilatant behavior in China clay suspensions,”Trans. Brit. Ceram. Soc.,64(11), 531–548 (1965).

Th. Plaul,Technologie der Grosskeramik, Band 1, Verlag für Bauwesen, Berlin (1964).

I. M. Gor’kova,Physicochemical Investigation of Sedimentary Rocks for Construction Purposes [in Russian], Stroiizdat, Moscow (1975).

N. Staneva, I. Kasabov, and W. Zotchev, “Rheological behavior of whiteware casting slips,”Interceram. 43(5), 346–347 (1994).

Yu. E. Pivinskii, “Rheology and technology of ceramics and refractories. Part 4. Thixotropic systems and factors determining their properties,”Ogneupory, No. 10, 9–16, (1996).

Yu. E. Pivinskii,New Refractory Concretes [in Russian], BelGTASM, Belgorod (1996).

N. B. Ur’ev,Physicochemical Principles of the Technology of Dispersed Systems and Materials [in Russian], Khimiya, Moscow (1988).

C. Lewgrand, “Rheologie des melanges de ciment ou de sable et d’eau,”Rev. Mater. Constr., No. 659-660, 217–222 (1971).

N. N. Kruglitskii and Yu. E. Pivinskii, “Effect of temperature on the dilatancy of mineral suspensions,”Fiz-Khim. Mekh. Liof. Disp. Sistem, No. 6, 111–113 (1974).

Yu. E. Pivinskii and N. N. Kruglitskii, “Effect of temperature on the rheological behavior of disperse non-Newtonian systems,”Kolloidn. Zh.,37(5), 997–1001 (1975).

V. B. Deryagin,Theory of Stability of Colloids and Thin Films [in Russian], Nauka, Moscow (1986).

N. N. Kruglitskii and Yu. E. Pivinskii,Principles of Rheology [in Ukrainian], Znanie, Kiev (1973).

Yu. E. Pivinskii, “Principles of ceramic concrete technology,”Ogneupory, No. 2, 34–42 (1978).

A. A. Trapeznikov, G. G. Petrzhik, and T. I. Korotina, “Rheological and dielectric properties of dilatant and thixotropic systems,”Dokl. Akad. Nauk SSSR,176(2), 378–381 (1967).

Yu. E. Pivinskii and G. Ya. Akimov, “On the process of semifinished-product densification during molding and pressing of ceramic materials,” in:Refractory Materials and Articles: Investigations and Technological Developments (A Topical Collection of Scientific Works of the All-Union Research Institute of Refractories) [in Russian], Metallurgiya, Moscow (1987), pp. 26–30.

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 4, pp. 2–14, April, 1997.

For the previous articles of this series see Refractories and Industrial Ceremics No. 3 (1994), No. 12 (1995), Nos. 1 and 10 (1996), and No. 2 (1997).

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E. Rheology in the technology of ceramics and refractories. Part 6. Dilatant systems and factors determining their properties. Refract Ind Ceram 38, 131–142 (1997). https://doi.org/10.1007/BF02767924

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767924