Abstract

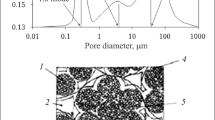

Results of studying the effect of the packing inhomogeneity of the powder compact on the strength of sintered corundum ceramics are presented. In the powders used for molding powder compacts, agglomerates of various sizes were formed artificially. Under the same sintering conditions no substantial difference in the density or grain size of materials that initially differed in the inhomogeneity of particle packing were observed. Strength measurements revealed an inverse dependence of the strength on the degree of powder inhomogeneity in the starting compact.

Similar content being viewed by others

References

A. V. Galakhov, I. V. Vyazov, V. Ya. Shevchenko, and A. A. Ezhov, “On the effect of the porous structure of a submicron-powder pressing on the strength of the zirconium dioxide ceramics,”Izv. Akad. Nauk SSSR, Neorg. Mater.,26(4), 828–833 (1990).

W. H. Rhodes, “Agglomerate and particle size effects on sintering yttria-stabilized zirconia,”J. Am. Ceram. Soc.,64(1), 19–22 (1981).

A. V. Galakhov, S. V. Kutsev, V. A. Kryuchkov, et al., “Effect of the molding pressure on the sintering of submicron powders of tetragonal zirconium dioxide,”Ogneupory, No. 1, 5–11 (1993).

A. V. Galakhov, E. V. Tsibailo, M. I. Yanovskaya, and I. A. Litvinov, “Grain growth in the sintering of compacts made of submicron powders,”Ogneupory Tekhn. Keram., No. 4, 17–21 (1997).

“Mechanical properties of pure, dense aluminium oxide as a function of grain size,” Sci. Sinter., 18, Spec. Issue, 41–49 (1986).

N. McN. Alford, J. D. Birchall, and K. Kendall, “High-strength ceramics through colloidal control to remove defects,”Nature,330(10), 51–53 (1987).

A. V. Galakhov, E. V. Tsibailo, G. A. Fomina, and V. S. Mitin, “Analysis of agglomerated packings,”Ogneupory, No. 4, 14–17 (1995).

E. S. Lukin, “Contemporary high-density oxide ceramics with a regulated microstructure. Part I. Effect of aggregation of oxide powders on the sintering and microstructure of ceramics,”Ogneupory Tekhn. Keram., No. 1, 5–14 (1996).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 5, pp. 14–19, May, 1997.

Rights and permissions

About this article

Cite this article

Galakhov, A.V., Tsibailo, E.V. Inhomogeneity of powder packing in compacts and strength of the ceramics obtained. Refract Ind Ceram 38, 184–188 (1997). https://doi.org/10.1007/BF02767844

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767844