Abstract

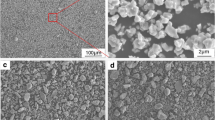

A procedure for manufacturing multilayer ceramic products functional from the Si3N4- and BN-based composite material is developed. A correlation is found between the chemical composition of the starting material, the production procedure, the microstructure and physicochemical properties of the final product, the serviceability, and the field of product application. This makes it possible to speed up the design of other products made of the aforementioned material. The material is considered promising in view of results of testing parts of molds intended for molding heat-resistant glass and lenses.

Similar content being viewed by others

References

“Functionally gradient materials,” Atoms Jpn., 39(9), 32–33 1995).

N. I. Ershova, I. Yu. Kelina, and V. M. Zemlyanskaya, “Hotmolded composite materials in the silicon nitride-boron nitride system,”Ogneupory, No. 11, 17–21 (1995).

N. I. Ershova, I. Yu. Kelina, and Z. V. Pavlova, “A study of the possibility of using Si3N4—BN material in bearing cages,” in:Composite-Material Structures [in Russian], NPO Prikladnoi Mekhaniki, Moscow (1993), No. 4, pp. 36–39.

N. I. Ershova, L. P. Tikhonova, L. N. Gremza, and I. Yu. Kelina, “A study of the applicability of nitride ceramics in mold parts for molding glasses,” in:Structures and Production Technology of Articles Made of Nonmetal Materials [in Russian], ONPO Tekhnologiya, Obninsk (1992), p. 11.

R. W. Rice, J. H. Enloe, J. W. Lau, E. Y. Luh, and L. E. Lalhert, “Hot-pressing—a new route to high performance ceramic multilayer electronic packages,”Am. Ceram. Soc. Bull.,71(5), 751, 753–755 (1992).

Review of Foreign Patents on Application of Ceramics as Turbine Components [in Russian], TsIAM, Moscow (1985), No. 207, pp. 62–78.

E. N. Chasovskoi, E. N. Pozdnyakova, N. I. Ershova, and A. A. Selunskii, “Numerical analysis of the thermal stress of (Si3N4−Y2O3)—BN composite material intended for use in rotor seals,” in:Structures and Production Technology of Articles Made of Nonmetal Materials, Part I. Refractory Ceramic Materials [in Russian], VIMI, Moscow (1990), p. 58.

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 5, pp. 6–10, May, 1997.

Rights and permissions

About this article

Cite this article

Ershova, N.I., Kelina, I.Y. Multilayer ceramic products made of Si3N4-and BN-based composite material. Refract Ind Ceram 38, 175–179 (1997). https://doi.org/10.1007/BF02767842

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767842