Abstract

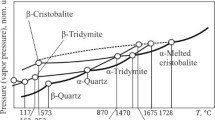

The laws of phase formation in silica gel products obtained using a limestone residue are established. Results of x-ray diffraction, petrographic, and other analyses show that the process of transformation of quartz into high-temperature modifications of silica gel proceeds at a markedly higher rate if the limestone residue is used in a mixture with pyrite cinder rather than with a conventional lime-iron additive. This is related to certain special features of the mineralizer composition and the physicochemical processes involved in the firing. The temperature dependence and kinetics of the conversion of silica gel into its high-temperature structural modifications during the firing of dinas with dry mineralizers were studied in the course of heating in the temperature range from 1200 to 1420°C and during a hold at the maximum heat-treatment temperature. Equations describing the structural transformation processes are derived. A relationship between the physico-chemical properties of the samples and the features of the phase formation processes is demonstrated.

Similar content being viewed by others

References

I. V. Khonchik, V. I. Drozd, B. G. Alapin, et al., “New types of calcium-containing mineralizers for the production of dinas articles,”Ogneupory, No. 7, 7–10 (1991).

V. L. Bulakh, I. V. Khonchik, and S. N. Romanenko, “Development of dinas technology using dry mineralizers,”Ogneupory, No. 8, 19–21 (1991).

I. V. Khonchik, N. M. Kvasman, and V. L. Bulakh, “Optimization of the physicochemical properties of silica gel articles by the method of simplex-network planning,”Ogneupory, No. 10, 17–19 (1991).

G. V. Kukolev,Chemistry of Silicon and Physical Chemistry of Silicates [in Russian], Vysshaya Shkola, Moscow (1966).

A. A. Baikov,Physicochemical Conditions for the Production of Refractory Products, A Collection of Papers, Vol. 5 [in Russian], Acad. Sci. USSR, Moscow (1948).

D. S. Belyankin, B. V. Ivanov, and V. V. Lapin,Petrography of Technical Rocks [in Russian], Acad. Sci. USSR, Moscow (1952).

I. S. Kainarskii and A. I. Karyakin, “On the conversion of quartz into tridymite,”Dokl. Akad. Nauk SSSR,86(1), 137–140 (1952).

P. S. Mamykin, “On the general theory of mineralizers for dinas production,” in:A Collection of Papers Devoted to the 60th Birthday of P. P. Budnikov, [in Russian] (1946), pp. 143–153.

N. F. Lebedev,Physicochemical and Technological Study of Dinas Production from Portland Cement, Candidate's Thesis [in Russian], Sverdlovsk (1975).

G. V. Kukolev,Dinas Formation in the Course of Firing, Trudy UkrNIIO i Kislotouporov, Issue 36 [in Russian], ONTI Gostekhizdat Ukrainy, Kharkov (1935).

A. S. Berezhnoi,Multicomponent Oxide Systems [in Russian], Naukova Dumka, Kiev (1970).

E. F. Osborn, “Phase diagrams of refractories,”Am. Ceram. Soc. Bull.,56(7), 654–659 (1977).

I. S. Kainarskii,Dinas [in Russian], Metallurgizdat, Moscow (1961).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 2, pp. 17–21, February, 1997.

Rights and permissions

About this article

Cite this article

Khonchik, I.V., Drozd, V.I. & Alapin, B.G. Kinetics of structural transformations in silica gel and physicochemical processes involved in the firing of dinas refractories containing dry mineralizers. Refractories and Industrial Ceramics 38, 62–66 (1997). https://doi.org/10.1007/BF02767835

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767835