Abstract

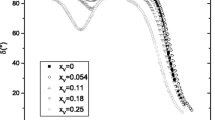

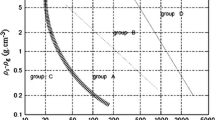

A great majority of high-density ceramic binding suspensions (HDBS) and the related molding systems, characterized by a volume fraction of the solid phaseC v=0.80−0.85, exhibit a strongly pronounced dilatancy that is a source of difficulties for the production and use of these materials. The effect of dilatancy and the mechanism of dilatant flow are analyzed from the standpoint of thermodynamics and colloid chemistry. Original experimental results and published data are generalized and a classification of the main types of dilatancy is proposed. The effects of some important factors on the character of dilatant flow in high-density ceramic binding suspensions based on quartz glass, quartz sand, mullite, and titanium dioxide are considered.

Similar content being viewed by others

References

Yu. E. Pivinskii,Ceramic Binders and Ceramic Concretes [in Russian], Metallurgiya, Moscow (1990).

M. Reiner,Deformation and Flow [Russian translation], Neftegortopizdat, Moscow (1963).

N. B. Ur'ev,Physicochemical Principles of the Technology of Disperse Systems and Materials [in Russian], Khimiya, Moscow (1988).

L. I. Peregudova, A. V. Akol'zina, N. B. Ur'ev, et al., “Colloidal-chemical properties of zinc-silicate compositions,”Kolloidn. Zh.,57(5), 709–712 (1995).

N. B. Ur'ev and A. A. Potanin,Flowability of Suspensions and Powders [in Russian], Khimiya, Moscow (1992).

Yu. E. Pivinskii, “On the thixotropy and dilatancy of ceramic suspensions of fused quartz,”Zh. Prikl. Khim.,456(9), 1917–1922 (1972).

Yu. E. Pivinskii, “Rheological and sedimentation properties of ceramic suspensions with granulated fillers,”Ogneupory, No. 4, 52–57 (1972).

Yu. E. Pivinskii, “Rheological properties of aqueous silica gel suspensions,”Kolloidn. Zh.,35(2), 289–295 (1973).

Yu. E. Pivinskii, “Study of dilatancy in mineral suspensions of various concentrations,”Fiz.-Khim. Mekh. Liof. Disp. Sistem, No. 6, 182–187 (1974).

N. N. Kruglitskii and Yu. E. Pivinskii, “Effect of temperature on dilatancy of mineral suspensions,”Fiz.-Khim. Mekh. Liof. Disp. Sistem, No. 6, 111–113 (1974).

N. N. Kruglitskii and Yu. E. Pivinskii,Principles of Rheology, Znanie, Kiev (1973).

N. N. Kruglitskii and Yu. E. Pivinskii, “On classification of the types of rheological behavior of dilatant disperse systems,”Dokl. Akad. Nauk UkrSSR, Ser. B, No. 3, 258–261 (1974).

Yu. E. Pivinskii and A. G. Romashin,Quartz Ceramics [in Russian], Matallurgiya, Moscow (1974).

Yu. E. Pivinskii and A. I. Natsenko, “Rheological and technological properties of mixed suspensions based on refractory components,”Ogneupory, No. 11, 49–55 (1974).

Yu. E. Pivinskii and N. N. Kruglitskii, “Effect of temperature on the rheological behavior of disperse non-Newtonian systems,”Kolloidn. Zh.,37(5), 997–1001 (1975).

Yu. E. Pivinskii, “Principles of ceramic concrete technology,”Ogneupory, No. 3, 34–42 (1978).

Yu. E. Pivinskii and R. G. Makarenkova, “The effect of granulated filler on the rheological properties of ceramic suspensions,”Ogneupory, No. 12, 39–44 (1978).

Yu. E. Pivinskii, “Study of the rheological and binding properties of quartz sand suspensions,”Ogneupory, No. 6, 39–45 (1980).

Yu. E. Pivinskii and P. L. Mityakin, “Rheological and binding properties of high-silica-gel suspensions,”Ogneupory, No. 5, 48–52 (1981).

V. A. Bevz and Yu. E. Pivinskii, “Obtaining binding suspensions and ceramic concretes on the basis of dinas,”Ogneupory, No. 9, 46–51 (1981).

N. N. Kruglitskii and Yu. E. Pivinskii, “Effect of stabilization and coagulation on the dilatancy of mineral suspensions,”Khim. Tekhnol., No. 1, 22–24 (1981).

Yu. E. Pivinskii, “On the phase relations, important technological properties, and classification of ceramic and other binder systems,”Ogneupory, No. 6, 49–60 (1982).

Yu. E. Pivinskii, “Volumetric and phase characteristics and their effect on the properties of suspensions and ceramic mold systems,”Ogneupory, No. 11, 50–58 (1982).

Yu. E. Pivinskii, “On the stabilization and aging of ceramic suspensions,”Ogneupory, No. 8, 15–22 (1983).

Yu. E. Pivinskii, N. T. Kotova, and F. S. Kaplan, “Highly concentrated suspensions of nontransparent quartz glass and related materials,”Ogneupory, No. 6, 14–19 (1986).

Yu. E. Pivinskii, “Highly concentrated ceramic binding suspensions. Principles of technology,”Ogneupory, No. 10, 3–9 (1987).

Yu. E. Pivinskii, “Highly concentrated ceramic binding suspensions. Stabilization, rheological properties, and principles of rheotechnological compatibility,”Ogneupory, No. 6, 6–13 (1988).

F. S. Kaplan and Yu. E. Pivinskii, “Rheological and colloidal-chemical properties of disperse ceramic systems,” in:Chemistry and Technology of Silicate and Refractory Nonmetallic Materials [in Russian], Nauka, Leningrad (1989), pp. 125–141.

F. S. Kaplan, Yu. E. Pivinskii, and A. N. Saprykin, “On features of dilatant strengthening of quartz glass suspensions,”Kolloidn. Zh.,50(6), 1092–1098 (1988).

F. S. Kaplan and Yu. E. Pivinskii, “Study of the effect of dispersion composition on the rheological properties of highly concentrated silica gel suspensions,”Kolloidn. Zh.,54(4), 73–79 (1992).

Yu. E. Pivinskii, “Refractory concretes of a new generation. Colloidal-chemical aspects of the technology,”Ogneupory, No. 1, 4–12 (1994).

Yu. E. Pivinskii, “Refractory concretes of new generation. Rheological aspects of technology,”Ogneupory, No. 4, 6–14 (1994).

H. Freundlich and H. L. Roder, “Thixotropy and dilatancy,”Trans. Faraday Soc.,34(202), 308–316 (1938).

W. H. Bauer and E. A. Collins, “Thixotropy and dilatancy,”Rheol. Theory Appl.,IV(4), 423–459 (1967).

A. B. Metzner and M. Whitlok, “Factors influencing dilatant behavior of suspensions,”Trans. Soc. Rheol.,2(2), 239–247 (1958).

M. K. Gal'perina and I. V. Kolyshkina, “Study of the rheological properties of clay slips,”Trudy Gos. NIIStroikeramika, No. 53, 5–16 (1983).

I. F. Efremov, G. M. Lukashenko, and É. A. Terent'eva, “The formation and properties of periodic colloidal structures,” in:Surface Forces in Thin Films [in Russian], Nauka, Moscow (1979), pp. 20–29.

I. F. Efremov, G. M. Lukashenko, and É. A. Terent'eva, “Dilatancy of colloidal structures,”Kolloidn. Zh.,42(5), 859–866 (1980).

I. F. Efremov, “Dilatancy of colloidal structures and polymer solutions,”Usp. Khim.,51(2), 285–310 (1982).

P. F. Ovchinnikov, “Rheological equations of thixotropic-dilatant structures,”Kolloidn. Zh.,40(2), 263–269 (1978).

P. F. Ovchinnikov,Vibrorheology [in Russian], Naukova Dumka, Kiev (1983).

M. N. Avdeev, “Characteristics of the structural-mechanical properties of dilatant disperse systems,” in:Selected Physico-Mechanical Studies of Liquid Systems [in Russian], Rostov-on-Don (1974), pp. 131–136.

A. W. Dobrovolskiy, “Development of slip moulding methods,”Ceramurgia Intern.,3(4), 156–164 (1977).

R. Lenk, “Rheologische Eigenschaften von SiC-Spritzgiebmassen,”Sprechsaal,124(9), 563–573 (1991).

Yu. E. Pivinskii, “Rheology in the technology of ceramics and refractories. 2. Disperse systems. Experimental techniques and methods of estimation of the rheological properties,”Ogneupory, No. 12, 11–19 (1995).

Yu. E. Pivinskii, “Rheology in the technology of ceramics and refractories. 3. Thixotropy and the classification of thixotropic systems,”Ogneupory, No. 1, 14–20 (1996).

Yu. E. Pivinskii, “Rheology in the technology of ceramics and refractories. 3. Thixotropic systems and factors determining their properties,”Ogneupory, No. 10, 9–16 (1996).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory i Tekhnicheskaya Keramika, No. 2, pp. 8–16, February, 1997.

For the previous articles of this series see No. 3 (1994), No. 12 (1995), and Nos. 1 and 10 (1996).

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E. Rheology in the technology of ceramics and refractories. Part 5. Dilatancy: Classification and types of dilatant systems. Refractories and Industrial Ceramics 38, 54–61 (1997). https://doi.org/10.1007/BF02767834

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767834