Abstract

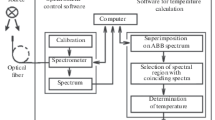

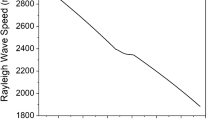

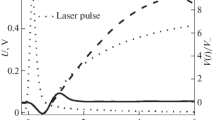

We propose a method for measurement of temperature and the heating and cooling rates of the surface of metal alloys in the process of pulse laser treatment and estimate the dynamic error of measurements. We obtain experimental dependences of heating and cooling of the nonirradiated surface of a Fe83B17 specimen and demonstrate the possibility of registering thermal processes with heating and cooling rates of up tol06K/sec.

Similar content being viewed by others

References

V. S. Kovalenko, Yu. A. Kunitskii, L. F. Golovko, and B. S. Davydov,Amorphization of the Surface of Materials under Energy Action [in Russian], Kiev Polytechnic Institute, Kiev (1983).

Yu. K. Kovneristyi, “Amorphous metallic materials,”Metalloved. Term. Obrab. Met., No. 9, 2–8 (1983).

N. A. Yaryshev,Theoretical Foundations of Measurement of Nonstationary Temperatures [in Russian], ènergiya, Leningrad (1967).

I. S. Miroshnichenko,Quenching from the Liquid State [in Russian], Metallurgiya, Moscow (1982).

O. A. Gerashchenko, A. N. Gordov, V. I. Lakh, et al.Temperature Measurements. A Handbook [in Russian], Naukova Dumka, Kiev (1984).

N. N. Rykalin, A. A. Uglov, I. V. Zuev, and A. N. Kokora,Laser and Electron-Beam Treatment of Materials. Handbook [in Russian], Mashinostroenie, Moscow (1985).

V. I. Denisenko, V. G. Prokoshev, and D. V. Abramov, “Dynamic processes during laser hardening of coatings made of chromium.”Teplofiz. Vys. Temp.,36, No. 4, 674–684 (1998).

F. Kh. Mirzoev, V. Ya. Panchenko, and L. A. Shelepin, “Laser control over processes in a solid,”Usp. Fiz. Nauk,166. No. 1. 3–7 (1996).

G. P. Kokurina, A. A. Katasonov, and A. N. Rumynskii, “Thermoelastic stresses induced by laser irradiation in translucent materials,”Teplofiz. Vys. Temp.,34, No. 4, 597–606 (1996).

S. G. Rabinovich,Measurement Errors [in Russian], ènergiya, Moscow (1978).

B. S. Davydov and O. A. Vostrov,Influence of the Form of a Laser Pulse on the Space and Time Distributions of Temperature. Creation and Utilization of Laser Technique and Technology in Machine Building and Instrument Making [in Russian], Tekhnika, Kiev (1985).

V. S. Kraposhin. “Treatment of the surface of metal materials by laser irradiation.”Poverkhn. Fiz. Khim., Mekh., No. 3, 3–12 (1982).

A. E. Bell, “Review and analysis of laser annealing,”RCA Rev.,40, No. 9, 295–338 (1979).

A. A. Samarskii,Introduction to Numerical Methods [in Russian], Nauka. Moscow (1982).

A. Bhattacharya and D. Streetman, “Dynamics of pulsed CO2-laser annealing of silicon,”J. Phys. Ser. D: Appl. Phys. 14, No. 5, 67–72(1981).

Yu. A. Kunitskii, V. N. Korzhik, and Yu. S. Borisov,Noncrystalline Metallic Materials and Coatings in Engineering [in Russian], Tekhnika, Kiev (1988).

D. M. Himmelblau,Applied Nonlinear Programming, McGraw-Hill, New York (1972).

Author information

Authors and Affiliations

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 36, No. 2, pp. 103–107, March-April, 2000.

Rights and permissions

About this article

Cite this article

Paustovskii, A.V., Gubin, Y.V. & Kunitskii, Y.A. Dynamic measurements of temperature in the process of pulse laser treatment of materials. Mater Sci 36, 274–279 (2000). https://doi.org/10.1007/BF02767548

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767548