Abstract

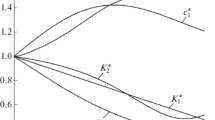

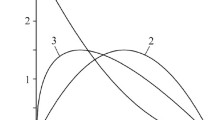

We propose a three-layer model of the process of braking. To determine the contact temperature and wear, we use an exponential dependence of the friction factor on temperature. By using the Laplace integral transformation with respect to time, we reduce the problem under consideration to a system of nonlinear Volterra-type equations. The results of numerical evaluation of the braking time, time of attainment of the maximum temperature, maximum contact temperature, and wear are presented in the graphic form.

Similar content being viewed by others

References

M. P. Aleksandrov,Brake Systems in Machine Building [in Russian]. Mashinostroenie. Moscow (1965).

Yu. N. Drozdov, V. G. Archegov, and V. I. Smirnov,Antiscuff Resistance of Rubbing Bodies [in Russian], Nauka. Moscow (1981).

E. V. Zinov’ev, “Thermal state and frictional characteristics of specimens made of polymeric composites in testing on various fric- tional-testing machines,” in:Thermal Dynamics of Friction [in Russian], Nauka, Moscow (1970). pp. 92–106.

V. N. Parfenov and S. S. Kokonin, “Temperature problem of friction in loaded multidisk brakes,” in:Problems of Nonstationary Friction in Machines, Instruments, and Devices [in Russian], Nauka, Moscow (1978). pp. 98–119.

A. V. Chichinadze,Numerical Analysis and Investigation of External Friction in the Process of Braking [in Russian]. Nauka. Mos- cow (1967).

A. V. Chichinadze, è. D. Braun, A. G. Ginzburg, and Z. V. Ignateva,Numerical Analysis, Testing, and Selection of Friction Couples [in Russian], Nauka, Moscow (1979).

O. O. Evtushenko and Yu. O. Pyr’ev, “Solution of the system of equations of thermal dynamics of friction in the process of braking,”Dop. Nat. Akad. Nauk Ukrainy, No. 10, 71–77 (1997).

Z. Olesiak, Yu. Pyryev, and A. Yevtushenko, “Determination of temperature and wear during braking,”Wear, 210, Nos. 1-2, 120- 126(1997).

O. O. Evtushenko and Yu. O. Pyr’ev, “Evaluation of the contact temperature and wear in the process of braking,”Mat. Met. Fiz.- Mekh. Polya,40, No. 3, 108–112 (1997).

O. O. Evtushenko and Yu. O. Pyr’ev, “ Evaluation of the contact temperature and wear of frictional elements of brakes,”Fiz.-Khim. Mekh. Mater.,34, No. 2, 93–96 (1998).

I. G. Goryacheva and M. N. Dobychin,Contact Problems in Tribology [in Russian], Nauka, Moscow (1988).

M. Abramowitz and I. Stegun (editor),Handbook on Mathematical Functions with Formulas, Graphs, and Mathematical Tables, Nat. Bureau Stand. (1964).

Author information

Authors and Affiliations

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 36, No. 2, pp. 55–59, March-April, 2000.

Rights and permissions

About this article

Cite this article

Evtushenko, O.O., Pyr’ev, Y.O. Temperature and wear of the friction surfaces of a cermet patch and metal disk in the process of braking. Mater Sci 36, 218–223 (2000). https://doi.org/10.1007/BF02767542

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02767542