Abstract

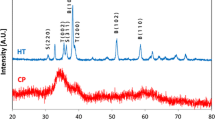

The effect of heat treatment at 1340 — 1450°C on the sintering of ceramic powders of the A12O3-ZrO2-Y2O3 system obtained by the method of rapid solidification of the melt is considered. It is shown that in this temperature range powder particles undergo crystallization of the amorphous phase and an ε-A12O3 → α-A12O3 transformation with the formation of an intraparticle ultradisperse polycrystalline structure of an eutectic type. The system attains a thermodynamically equilibrium state. However, the sinterability of compacts from such powders increases substantially, which is associated with the elevated contribution of the intraparticle grain boundary diffusion into the diffusion mass transfer.

Similar content being viewed by others

References

N. Claussen, G. Lindemann, and G. Petzov, “Rapid solidification of the A12O3-ZrO2 system,”Ceram. Ind.,9(3), 83–86 (1983).

V. A. Kryuchkov, L. P. Ivanova, A. V. Galakhov, et al., “A12O3-ZrO2 ceramics from powders obtained by the method of rapid hardening from the melt,”Ogneupory, No. 6, 19–22 (1989).

A. V. Galakhov, V. A. Kryuchkov, L. P. Ivanova, et al., “Structure and phase composition of powders in the A12O3-ZrO2-Y2O3, system,”Neorg. Mater.,26(4), 823–827 (1990).

G. Cevales, “Phase equilibrium diagram of alumina-zirconia and examination of new phase 99% A12O3-1% ZrO2(ε-A12O3),”Bar. Bent. Keram. Ges.,45(5), 216–219 (1968).

V. I. Grishaev and V. I. Tostanovskii, “Special features of oxide structural ceramics from mechanically milled powders,”Ogneupory, No. 2, 20–23 (1993).

B. A. Nebder, R. P. Ingel, W. I. Donough, and J. R. Spann, “Novel ceramic microstructures from advanced processing,”Adv. Ceram. Mater.,1(2), 137–144(1986).

M. Yoshimura, M. Kaneko, and S. Somiya, “Crystallization of amorphous materials by rapid quenching of melt in the system ZrO2,-SiO2,-A12O3,”J. Ceram. Soc. Jpn.,95(2), 202–208 (1987).

E. B. Slamovich and F. E. Lange, “Densification behavior of single-crystal and polycrystalline spherical particles of zirconia,”J. Am. Ceram. Soc.,73(11), 3368–3375 (1990).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kryuchkov, V.A., Galakhov, A.V. Sintering of powders in the Al2O3-ZrO2-Y2O3 system obtained by the method of rapid solidification of the melt as a function of the initial heat treatment. Refract Ind Ceram 39, 237–238 (1998). https://doi.org/10.1007/BF02765072

Issue Date:

DOI: https://doi.org/10.1007/BF02765072