Abstract

A multimillion rupee 500-ton hydraulic extrusion/forging facility established at NPL, New Delhi, has been used to undertake extensive studies in forming, the process of plastically deforming, which is the most important way of shaping materials. Wrought materials are used extensively for making useful products employing extrusion and forging, the two important secondary processing techniques used to convert materials into useful shapes and sizes and also to improve the mechanical and metallurgical properties. The success of these processes depends on the proper control and eventual optimization of different process variables.

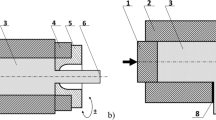

Different ferrous and non-ferrous materials including 316 and 321 stainless steels (using glass lubrication), aluminium brass, admiralty brass and 70/30 and 90/10 cupro nickels have been extruded at a lab-scale production level to determine the influence of different extrusion variables such as temperature, strain rate, extrusion ratio, different die design and several different compositions of lubricants on pressure requirement and surface quality of the products.

In the case of ferrous extrusions, the choice of billet-container lubricant has a marked effect on the shape of pressure-distance curves by influencing the effective coefficient of friction and heat transfer coefficient. Temperature, extrusion ratio and strain rate mainly influence the level of pressure-distance curves. Significance of specially designed dish shaped dies, avoiding the dead metal zone and the importance of extrusion limit diagrams for different materials on the available press capacity has also been highlighted.

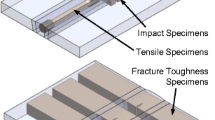

Deformation behaviour of the hi-tech materials; discontinuously reinforced metal matrix composites (MMCs) and aluminium-lithium alloys using hot extrusion and closed die forging, have been carried out. Parameters have been optimized to extrude rods and thin walled circular MMC tubes of aluminium alloy (2124/6061)-SiCp MMCs having varying volume fractions of SiCp. This developmental work has been carried out using powder metallurgy, liquid metallurgy and spray atomization and deposition routes, in joint collaboration with several R & D organizations.

Hot extrusion being an important production technique, results of these experiments can be directly transferred to industries. Similar deformation studies either by closed die or by isothermal forging have been made to develop components.

The pilot plant level facility is available for any industry for carrying out developmental R & D work. NPL welcomes such collaboration.

Similar content being viewed by others

References

Allison John E and Cole Gerald S 1993 JOM 19

Barraclough D R and Sellars C M 1974Mechanical properties of high rates of strain (London: Institute of Physics) p. 111

Bhat B V R, Mahajan Y R, Roshan M Md and Prasad Y V R K 1992Metall. Trans. A23 2223

Cockroft R 1969Metall. Mater. 3 351

Cook C R 1972Lubric. Eng. 28 199

Cox R 1964J. Iron Steel Inst. 202 246

Cox R, Mchugh T and Kirk F A 1960J. Iron Steel Inst. 194 423

Farag M M and Sellars C M 1973J. Inst. Met. 101 137

Forney R C 1986J. Met. 38 18

Gegel H L, Malas J C, Doraivelu S M and Shende V A 1987Metal Handbook (Materials Park, Ohio: ASM International) p. 417

Geiger A L and Jackson M 1989Adv. Mater. Proc. 136 23

Gupta A K, Goswami R K and Sikand R 1994Mater. Sci. & Technol. 10 1063

Gupta A K and Hughes K E 1979Metallurgia 46 644

Gupta A K and Krishnadas Nair C G 1989Proceedings of science and technology of aluminium lithium alloys (Bangalore: Aluminium Assoc. of India) p. 137

Gupta A K, Hughes K E and Sellars C M 1980Met. Technol. 323

Gupta A K, Sikand R, Raghvendra Rao S and Jayaram A R 1991Proc. INC AL 2 475

Gupta M, Sikand R and Gupta A K 1994Scr. Metall. Mater. 30 1343

Hepworth K 1978 Private Communications

Hughes K E 1973Metallurgist 6 572

Hughes K E and Sellars C M 1972J. Iron Steel Inst. 210 661

Hughes K E and Sellars C M 1974Metallurgist 6 201

Hughes K E, Nair K D and Sellars C M 1974Met. Technol. 1 161

Hughes K E, Plaut R L and Sellars C M 1982Met. Technol. 9 360

Humphreys F J 1990Proc. conf. recrystallization (ed.) T Chandra (Warrendale, PA: TMS) p. 113

Humphreys F J, Miller W S and Djazeb M R 1990Mater. Sci. Technol. 6 1323

Kuruvilla A K, Bhanuprasad V V, Prasad K S and Mahajan Y R 1989Bull. Mater. Sci. 12 495

Lavernia E J 1989Int. J. Rap. Solid 5 47

Liang X and Lavernia E J 1991Scr. Metall. Mater. 25 1199

Liversay D W and Sellars C M 1984Met. Technol. 11 149

Mitra R and Mahajan Y R 1993Defence Sci. J. 43 397

Pearson C E and Parkins R N 1961Extrusion of metals (London: Chapman and Hall)

Prasad Y V R K, Gegel H L, Doraivelu S M, Malas J C and Morgan J T 1984Metall. Trans. A15 1883

Rogers J A 1962 Ph D Thesis, University of Birmingham, UK

Rogers J A and Rowe G W 1967J. Inst. Met. 95 257

Rohatgi Pradip K 1993Defence Sci. J. 43 323

Sabroff A M 1963Metals Eng. Quarterly 31

Sejournet J 1956Rev. Metall. 53 572

Singer A R E 1970Met. Mater. 4 246

Singer A R E 1972J. Inst. Met. 100 185

Voight W 1928Lehrbuch der kristallphysik (Leipzig: Teubner) p. 716

Xia X, Sakaris P and McQueen H J 1994Mater. Sci. Technol. 10 487

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gupta, A.K. Processing of materials—monolithic to composites. Bull. Mater. Sci. 18, 773–810 (1995). https://doi.org/10.1007/BF02744810

Issue Date:

DOI: https://doi.org/10.1007/BF02744810