Abstract

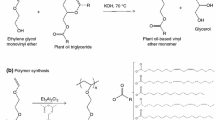

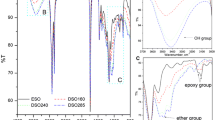

Cycloaliphatic epoxy resins are used in coatings and inks because of their exceptionally low viscosity and reactivity with a variety of co-reactants, thus permitting high-solids and zero VOC coatings. The low viscosity of epoxidized soybean oil (ESBO), its reactivity, and relatively low cost make it an inexpensive candidate co-resin in cationic thermally cured coatings and inks using blocked acid catalysts. Formulations with up to 40% ESBO in the epoxy resin blend were investigated. Blending of cycloaliphatic resin with 10% ESBO gave a bake coating with the same results as the standard formulation except pencil hardness was one unit lower when cured for 12 min at 120°C with a heat de-blocked catalyst. The hardness of coatings with ESBO is adjustable by changing the epoxy/polyol ratio, using harder polyols and harder epoxy resins.

Similar content being viewed by others

References

Eaton, R.F. and Lamb, K.T., “Liquid Sprayable Zero VOC Coatings Utilizing Cycloaliphatic Epoxies,”Proc. 23rd Waterborne, High-Solids, and Powder Coatings Symp., New Orleans, LA, February 14–16, 1996.

Union Carbide Bulletin UC-968, “Cyracure® Cycloaliphatic Epoxides Cationic UV Cure,” 1992.

Koleske, J.V., “Cationic Radiation Curing,”Federation Series on Coatings Technology, Federation of Societies for Coatings Technology, Blue Bell PA, 1991.

Muturi, P., Wang, D., Dirlikov, S., “Epoxidized Vegetable Oils as Reactive Diluents. I. Comparison of Vernonia, Epoxidized Soybean and Epoxidized Linseed Oils,”Prog. Org. Coat., 25, 85–94 (1994).

Crivello, J.V.,Macromolecular Reports, 1996, A33 (Suppls. 5 & 6), 251–262.

Raghavachar, R., Sarnecki, G., Baghdachi, J., and Massingill, J., “Cationic UV Cured Coatings using Epoxidized Soybean Oil,” RadTech Report, 12 (5), 36–40 (1998).

Wicks, Z.W., Jones, F.N., and Pappas, S.P.,Organic Coatings: Science and Technology, Vol. 1, John Wiley and Sons, New York, p. 134, 1992.

Alm, R.R., “Use of Amine Triflate Catalysts and Fluro-chemical Surfactants in High Solids Epoxy Coatings,”Journal of Coatings Technology,53, No. 683, 45 (1981).

Alm, R.R.,Mod. Paint Coat., p. 88 (Oct. 1980).

Union Carbide Bulletin UC-773, “Compliant Coatings Based on Cycloaliphatic Epoxies and Tone™ Polyols,” 1995.

Massingill, J.L., Sheih, P.S., Whiteside, R.C., Benton, D.E., and Morisse-Arnold, D.K., “Fundamental Studies of Epoxy Resins for Can and Coil Coatings II. Flexibility and Adhesion of Epoxy Resins,”Journal of Coatings Technology,62, No. 781, 31 (1990).

Author information

Authors and Affiliations

Additional information

Coatings Research Institute, 430 W. Forest Ave., Ypsilanti, MI 48197.

Rights and permissions

About this article

Cite this article

Raghavachar, R., Sarnecki, G., Baghdachi, J. et al. Cationic, thermally cured coatings using epoxidized soybean oil. J Coat Technol Res 72, 125–133 (2000). https://doi.org/10.1007/BF02733784

Issue Date:

DOI: https://doi.org/10.1007/BF02733784