Abstract

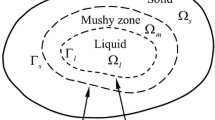

The process of solidification process is complex in nature and the simulation of such process is required in industry before it is actually undertaken. Finite element method is used to simulate the heat transfer process accompanying the solidification process. The metal and the mould along with the air gap formation is accounted in the heat transfer simulation. Distortion of the casting is caused due to non-uniform shrinkage associated with the process. Residual stresses are induced in the final castings. Simulation of the shrinkage and the thermal stresses are also carried out using finite element methods. The material behaviour is considered as visco-plastic. The simulations are compared with available experimental data and the comparison is found to be good. Special considerations regarding the simulation of solidification process are also brought out.

Similar content being viewed by others

References

Anderson BAB 1978 Thermal stresses in a submerged-arc welding joint considering phase transformations.J. Eng. Mater. Technol., Trans. ASME 100: 356–362

Basu B, Singh A K 1997 Role and characterization of double diffusive convection during solification of binary alloys.Proceedings of the Third ISHMT-ASME Heat and Mass Transfer Conference and Fourteenth National Heat Mass Transfer Conference, IIT, Kanpur, pp 129–141

Bellet M, Menai M, Bay F 1993 Finite element modelling of the cooling phase in casting processes.Modelling of casting, welding and advanced solidification processes VI (eds) T S Piwonka, V Voller, L Katgermann (The Minerals, Metals and Materials Society) pp 561–568

Campbell J 1991Casting (London: Butterworth Heinemann)

Chandra V 1995 Computer predictions of hot tears, hot cracks, residual stresses and distortions in precision castings. Basic concepts and approach.Proc. 124 TMS Annual Meeting, Warandale, PA, pp 107–117

Comini G, del Guidice S, Lewis R W, Zienkiewicz O C 1974 Finite element solution of nonlinear heat conduction problems with special reference to phase change.Int. J. Numer. Methods Engrg. 9: 109–127

Cormeau I C 1975 Numerical stability in quasi-static elasto-viscoplasticity.Int. J. Numer. Methods Engrg. 9: 109–127

Decultiex F, Menai M, Bay F, Levaillant C, Schmidt P, Svenson IL, Bellet M 1997 Thermomechanical modelling in casting with experimental validation.Modelling in welding, hot powder forming and casting (ed.) L Karlsson (Columbus, OH: ASM Int.) pp 291–313

Drezet J M, Roppaz M, Krahenbuhl Y 1995 Thermomechanical effects during direct chill and electromagnetic castings of aluminium alloys, Part II. Numerical solution.Proc. 124 TMS Annual Meeting, Warandale, PA, pp 941–950

Fjaer H G, Mo A 1990 ALSPEN, A mathematical model for thermal stresses in direct chill casting of aluminium billets.Metall. Trans. B21: 1049–1061

Grill A, Brimacombe J K, Weinberg F 1976 Mathematical analysis of stresses in continuous casting of steel.Ironmaking Steelmaking 1: 38–47

Guan J, Sahm P R 1992 Numerical investigations of thermal stresses in real 3D structural casting.Gisserei 8: 318–322

Heibler H, Zirngast J, Bernhard Ch 1994 Inner crack formation in continuous castings: Stress or strain criterion.Proc. 77 Steelmaking Conference, PA, vol. 77, pp 405–416

Hetu JF, Gao DM, Kabanemi KK, Bergeron S, Nguyen KT, Loong CA 1998 Numerical modelling of casting processes.Adv. Performance Mater. 5: 65–82

Inoue T, Ju D Y 1992 Simulation of solidification and viscoplastic stresses during vertical semi- continuous direct chill casting of aluminium alloys.Int. J. Plasticity 8:

Kelly JE, Michalek KP, O’Connor T G, Thomas B G, Dantzig JA 1988 Initial development of thermal and stress fields in continuous cast steel billets.Metall. Trans. A19: 1589–2602

Kowlowski PF, Thomas B G, Azzi JA, Wang H 1992 Simple constitutive equations for steel at high temperatures.Metall. Trans. B23: 903–918

Kuznetsov V, Vafai K 1995 Development and investigation of three phase model of the mushy-zone for analysis of porosity formation in solidifying castings.Int. J. Heat Mass Transfer 38: 2557–2567

Lewis R W, Bass B R 1976 The determination of temperature and stresses in cooling bodies by finite elements.ASME Trans., J. Heat Transfer 98: 478–484

Lewis R W, Morgan K, Galagher RH 1977Finite element analysis of solidification and welding processes (ASME)PVP-PB-026, pp 67–80

Lewis R W, Morgan K, Thomas H R, Seetharamu K N 1996The finite element mdethods in heat transfer analysis (New York: John Wiley)

Lewis R W, Seetharamu K N, Prasad B 1997 Modelling of heat transfer, fluid flow and thermodynamics in castings. InModelling in welding, hot powder forming and casting (ed.) L Karlsson (Columbus, OH: ASM Int.) pp 161–273

Lewis RW, Seetharamu KN, Hassan A Y 2001 Residual stress formation during casting. InHandbook of residual stress and distortion of steel (Columbus, OH: ASM Int.) ch. 5

Margin B, Katgerman L, Hannart B 1995 Physical and numerical modelling of thermal stress generation during DC casting of aluminium alloys.Proc. 7th Conf. on Modelling of Casting,Welding and Advanced Solidification Processes (TMC) pp 303–310

Morgan K, Lewis RW, Zienkiewicz OC 1978 An improved algorithm for heat conduction problems with phase change.Int. J. Numer. Methods Engrg. 12: 1191–1195

Morgan K, Lewis RW, Seetharamu KN 1981 Modelling heat flow and thermal stress in ingot casting.Simulation :55–63

Oddy AS, Lindgren LE 1997 Mechanical modelling and residual stresses.Modelling in welding, hot powder forming and casting (ed.) L Karlsson (Columbus, OH: ASM Int.) pp 31–59

Oddy A S, McDill J M J, Goldak J A 1990 Consistent strain fields in 3D finite elements analysis of welds.Trans. ASME, Press. Vessel Tech. 112: 309–311

Oeters F, Ruttiger K, Selenz H J 1977 Heat transfer in ingot pouring.Information Symp. On Casting and Solidification of Steel, Luxembourg, vol. 1, pp 126–167

Overfelt T 1992 The manufacturing of solidification modelling.J. Oper. Mainten. 44: 17–20

Overfelt T 1993 Sensitivity of a steel plate solidification model to uncertainties in thermophysical properties.Modelling of casting, welding and advanced solidification processes VI (eds) T S Piwonka, V Voller, L Katgermann (The Minerals, Metals and Materials Society) pp 663–370

Perzyna P 1966 Fundamental problems in visco-plasticity.Adv. Appl. Mech. 9: 243–377

Ruiz D J, Khandia Y 1995 Filling and solidification with coupled heat transfer and stress analysis.Proc. 7th Conf. on Modelling of Casting, Welding and Advanced Solidification Processes (TMS) pp 991–1006

Sarjant R J, Slack M R 1954 International temperature distribution on the cooling and reheating of steel ingots.J. Iron Steel Inst.: 428–444

Sathya Prasad B 1999Solidification simulation of casting using finite element method. Ph D thesis, Department of Mechanical Engineering, Indian Institute of Technology, Madras

Sevrin R 1970 Mathematical study of the thermal evolution of steel ingots.Mathematical models in metallurgical process developments (London: Iron & Steel Inst.) pp 147–157

Shapiro A, Stein W, Raboin P 1993 Casting process modelling using ProCAST and ST2D.Modelling of casting, welding and advanced solidification processes VI (eds) S Piwonka, V Voller, L Katgermann (The Minerals, Metals and Materials Society) pp 493–500

Steiger R V 1913Stahl Eisen 33: 1442

Stefanescu D M1995 Methodologies for modelling of solidification, micro structure and stress capabilities.Iron Steel Inst. Jpn. Int. 35: 637–650

Thomas B G, Samarasekara IV, Brimacombe JK 1988 Mathematical model of the thermal processing of steel ingots.Metall. Trans. B19: 119–147

Upadhya G, Paul A J 1994 Solidification modellig. A phenomenological review.AFS Trans. :69–80

Weingert H 1968Untersuchungen uber der Temperatur- und Erstarrung-sablanf Schwerer Blocke und Brammen. Ph D dissertation, Clausthal, Germany

Williams J R, Lewis RW, Morgan K 1979 An elasto-viscoplastic thermal stress models with application to the continuous casting of metals.Int. J. Numer. Methods Engrg. 14: 1–9

Yamanaka A, Nakajima K, Okamuza K 1995 Critical strain for internal crack formation in continuous casting.Ironmaking Steelmaking 22: 508–512

Yu K O, Nichols J J, Robinson M 1992 Finite element thermal modelling of casting microstructures and defects.J. Oper. Mainten. 44: 21–25

Zabaras N, Ruan Y, Richmond O 1991 On the calculations of deformations and stresses during axially symmetric solidification.Trans. ASME, J. Appl. Mech. 58: 865–871

Zhang Y F, Wang HP, Liu WK 1994 Fast acting simulation of simultaneous filling and solidification.Transport phenomenon in solidification (ASME) HTDV 284, pp 215–216

Zienkiewicz O C 1977The finite element method (London: McGraw Hill)

Zienkiewicz O C, Cormeau IC 1974 Visco-plasticity, plasticity and creep in elastic solids: A unified numerical solution.Int. J. Numer. Methods Engrg. 8: 821–845

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/BF02703389.

Rights and permissions

About this article

Cite this article

Seetharamu, K.N., Paragasam, R., Quadir, G.A. et al. Finite element modelling of solidification phenomena. Sadhana 26, 103–120 (2001). https://doi.org/10.1007/BF02728481

Issue Date:

DOI: https://doi.org/10.1007/BF02728481