Abstract

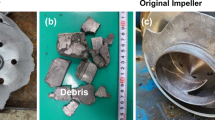

Failure of the pilot-scale test melter resulted from severe overheating of the Inconel 690 (690) jacketed molybdenum electrode. Extreme temperatures were required to melt the glass during this campaign because the feed material contained a very high waste loading. Metallurgical evaluation revealed the presence of an alloy containing nickel and molybdenum in several ingots found on the bottom of the melter and on a drip which had solidified on the electrode sheath. This indicates that a major portion of the electrode assembly was exposed to a temperature of at least 1317°C, the nickel/molybdenum eutectic temperature. Small regions on the end of the 690 sheath showed evidence of melting, indicating that this localized region exceeded 1345 °C, the melting point of 690. In addition to nickel, antimony was found on the grain boundaries of the molybdenum electrode. This also contributed to the failure of the electrode. The source of the antimony was not identified but is believed to have originated from the feed material.

Metallurgical evaluation also revealed that nickel had attacked the grain boundaries of the molybdenum/tungsten drain valve. This component did not fail in service; however, intergranular attack led to degradation of the mechanical properties, resulting in the fracture of the drain valve tip during disassembly. Antimony was not observed on this component.

Similar content being viewed by others

References

J.C. Marra:Ceram. Trans., 1996, vol. 78, p. 241.

T.B. Massalski:Binary Alloy Phase Diagrams, vol. 2, American Society for Metals, Metals Park, OH, 1987, p. 1611.

K.J. Imrich and C.F. Jenkins:Materials Performance in a Radioactive Waste/Glass Melter System Environment, Corrosion/96, National Association of Corrosion Engineers, Houston, TX, 1996.

H.P. Martinz, G. Leichtfried, and P. Wilhartitz:Ceram. Trans., 1996, vol. 78, p. 39.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Imrich, K.J. Failure analysis of a pilot scale melter. Practical Failure Analysis 1, 31–36 (2001). https://doi.org/10.1007/BF02715361

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02715361